Effect of feed per tooth, f, The entering angle, Applied – Sandvik Coromant Heat resistant super alloys User Manual

Page 74

72

f

z

h

ex

iC

Effect of feed per tooth, f

z

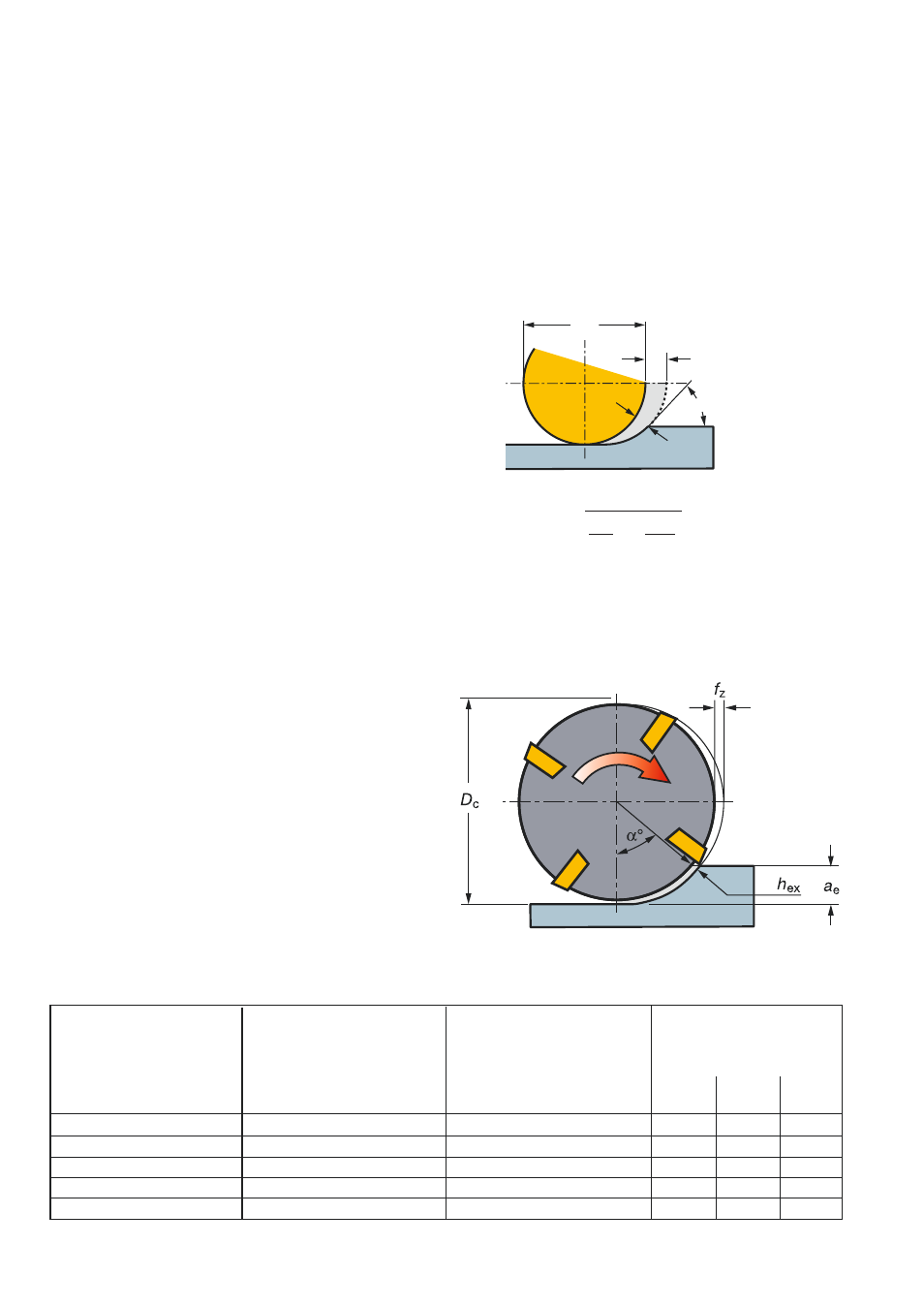

As with other workpiece materials, feed and depth of cut are also important for tool life

when machining HRSA materials. The feed per tooth value is calculated from the recom-

mended maximum chip thickness (h

ex

) – this deviates from the feed per tooth depending

upon the following two factors:

0.1

0.15

0.2

0.25

60°

1.16

0.12

0.17

0.23

0.2

53°

1.25

0.13

0.19

0.25

0.15

46°

1.4

0.14

0.21

0.28

0.1

37°

1.66

0.17

0.25

0.33

0.05

26°

2.3

0.23

0.34

0.46

Depth of cut

diameter ratio,

a

e

/D

c

Entering angle, α

Modification value, f

n

f

z

mm/tooth for given

chip thickness in mm:

Round inserts

Max chip thickness

h

ex

= f

z

×

sin

k

r

h

ex

=

f

z

×

√

4a

p

–

(

2a

p

)

2

iC iC

This is the width of the component engaged

in cut in relation to the diameter of the

cutter. It is the distance across the sur-

face being machined covered by the tool.

When the a

e

is below half the diameter the

maximum chip thickness is reduced rela-

tive to the f

z

– therefore the feed can be

increased.

Radial immersion, (a

e

/D

c

)

The entering angle (

k

r

) applied

h

ex

h

ex

h

ex

For inserts with an entering angle of 45º

and round inserts there is a chip thin-

ning effect – this allows greater feed than

inserts with

k

r

90º.