Ceramic insert grades – Sandvik Coromant Heat resistant super alloys User Manual

Page 24

22

Ceramic insert grades

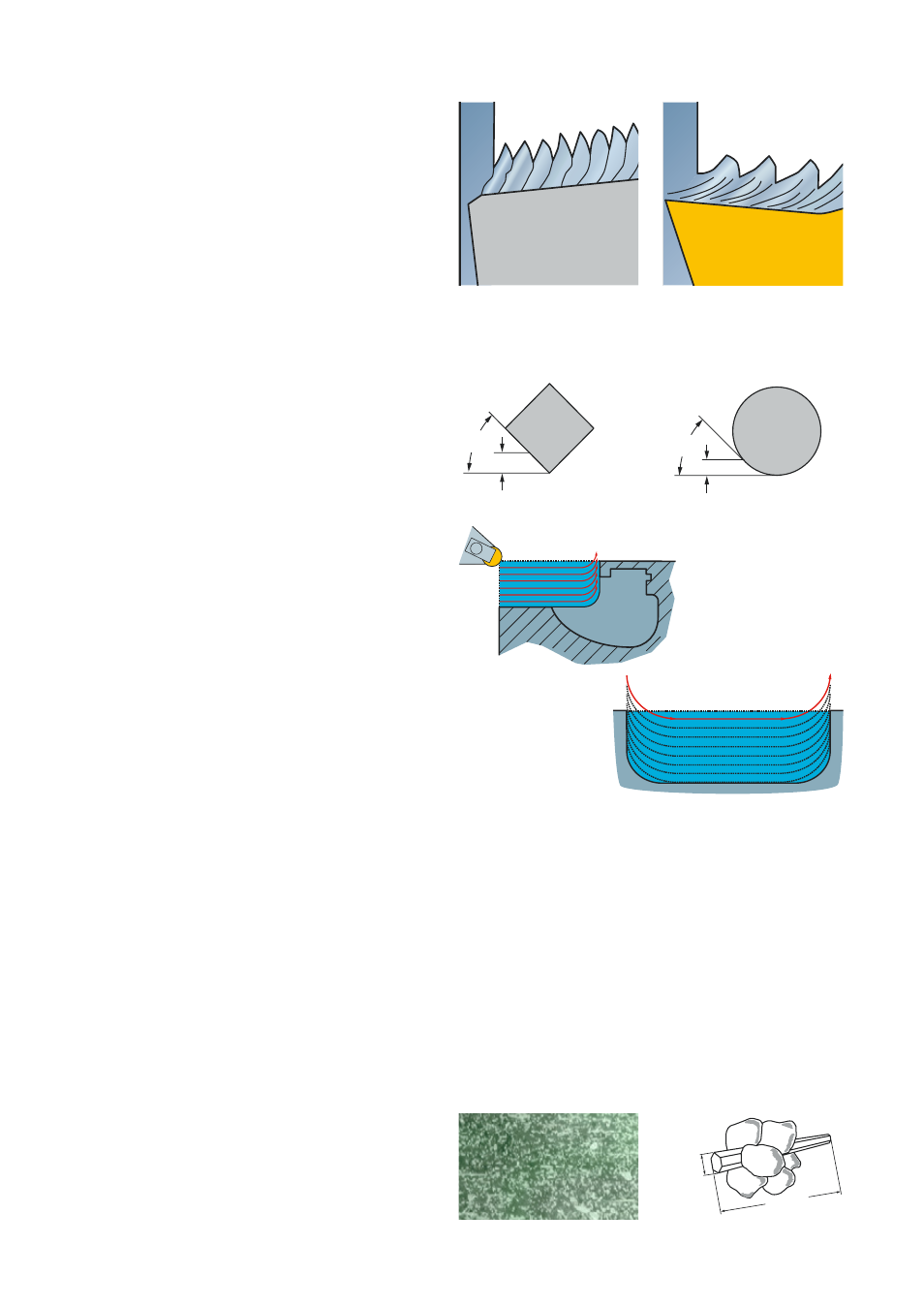

45º

>45º

Ceramic cutting materials offer excellent

productivity in roughing operations in FSM

and ISM. Their application differs greatly

compared to carbide due to their:

• High temperature resistance – allows

high cutting speed to be applied to pro-

duce a highly plasticised and sheared

chip.

• Low toughness – can lead to edge fritter-

ing, top slice and notch wear.

Both of these factors mean that for suc-

cessful application the following rules need

to be applied:

• Optimize entering angle at about 45° to

reduce notch, round or square inserts

should be used.

• Maximum chip thickness – between

0.08 to 0.15 mm.

• Optimized programming techniques

- to minimize notch on entry and long

passes.

- control the cutting arc of engagement in

corners.

There are 2 types of ceramics developed

for use in HRSA:

• Sialon – (Silicon, Aluminium, Oxygen,

Nitrogen) – a mixture of silicon nitride and

aluminium oxide. It has the best chemical

stability resisting notch wear:

- CC6060 – optimized choice for long

cutting lengths in clean material and for

profiling/pocketing with optimized pro-

gramming techniques.

- CC6065 – optimized for heavy roughing

applications, plunging and machining

direct into corner.

• Whiskered ceramic – to provide the

improved toughness and bulk strength

compared to the traditional ceramic,

fibres are included:

- CC670 – first choice for machining of

forged components with rough scale

and ovality.

Ceramics

Carbide

0.5 mm

10–80 mm