Sandvik Coromant Heat resistant super alloys User Manual

Page 119

117

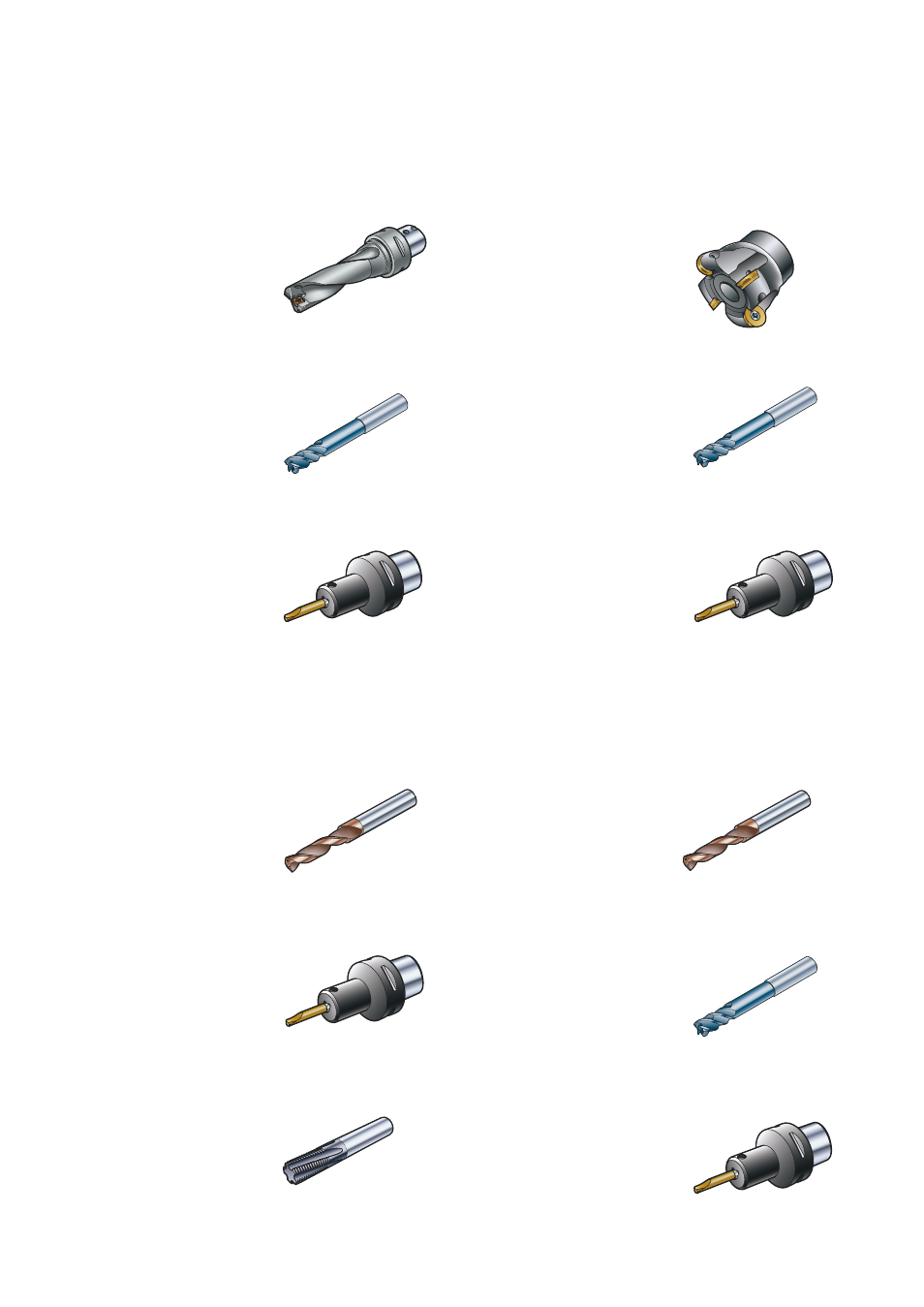

1 Drilling

CoroDrill 880 – Ø 21.00 mm

Central insert – LM 1044

Peripheral insert – LM 1044

v

c

30 m/min

f

n

0.05 mm/r

2. Circular milling – hole Ø 22 mm

CoroMill Plura R216.24 – Ø 12.00 mm

R216.24-12050CAK26P 1620

v

c

75 m/min

a

e

0.5 mm

f

z

0.1 mm/tooth

a

p

10 mm

3. Chamfering

Coromant Capto

CoroTurn XS

C4-CXS-47-06

CXS-06T045-20-6225R 1025

v

c

75 m/min

f

z

0.1 mm/tooth

1. Drilling

CoroDrill Delta-C R846 – Ø 7.00 mm

R846-0700-30-A1A 1220

v

c

25 m/min

f

n

0.1 mm/r

2. Finish boring

CoroMill Plura R216.24 – Ø 8.00 mm

R216.24-12050CAK26P 1620

v

c

40 m/min

f

n

0.2 mm/r

3. Chamfering

Coromant Capto

CoroTurn XS

C4-CXS-47-05

CXS-05T045-20-5220R 1025

v

c

75 m/min

f

z

0.1 mm/tooth

2. Circular milling – hole Ø 60 mm

CoroMill Plura R216.24 – Ø 12.00 mm

R216.24-12050CAK26P 1620

v

c

75 m/min

f

z

0.1 mm/tooth

a

p

10 mm

1. Circular ramping – hole Ø 59 mm

CoroMill 300 – Ø 35 mm

R300-12400E-MM 2040

v

c

25 m/min

f

z

0.2 mm/tooth

a

p

2.0 mm

3. Chamfering

Coromant Capto

CoroTurn XS

C4-CXS-47-06

CXS-06T045-20-6225R 1025

v

c

75 m/min

f

z

0.1 mm/tooth

1. Drilling

CoroDrill Delta-C R846 – Ø 6.90 mm

R846-0690-30-A1A 1220

v

c

25 m/min

f

n

0.1 mm/r

3. Thread milling

CoroMill Plura

R217.33C060240AC13N 1630

v

c

75 m/min

f

z

0.07 mm/tooth

2. Chamfering

Coromant Capto

CoroTurn XS

C4-CXS-47-05

CXS-05T045-20-5220R 1025

v

c

75 m/min

f

z

0.1 mm/tooth

OPERATION D

Ø 8 mm, hole 5 mm deep

OPERATION A

Ø 22 mm, hole 20 mm deep

OPERATION B

Ø 60 mm, hole 20 mm deep

OPERATION C

5/16-24 UNF, hole 15 mm deep

Hole making in the aerospace industry – aero engine