Examples of machining – Sandvik Coromant Heat resistant super alloys User Manual

Page 17

15

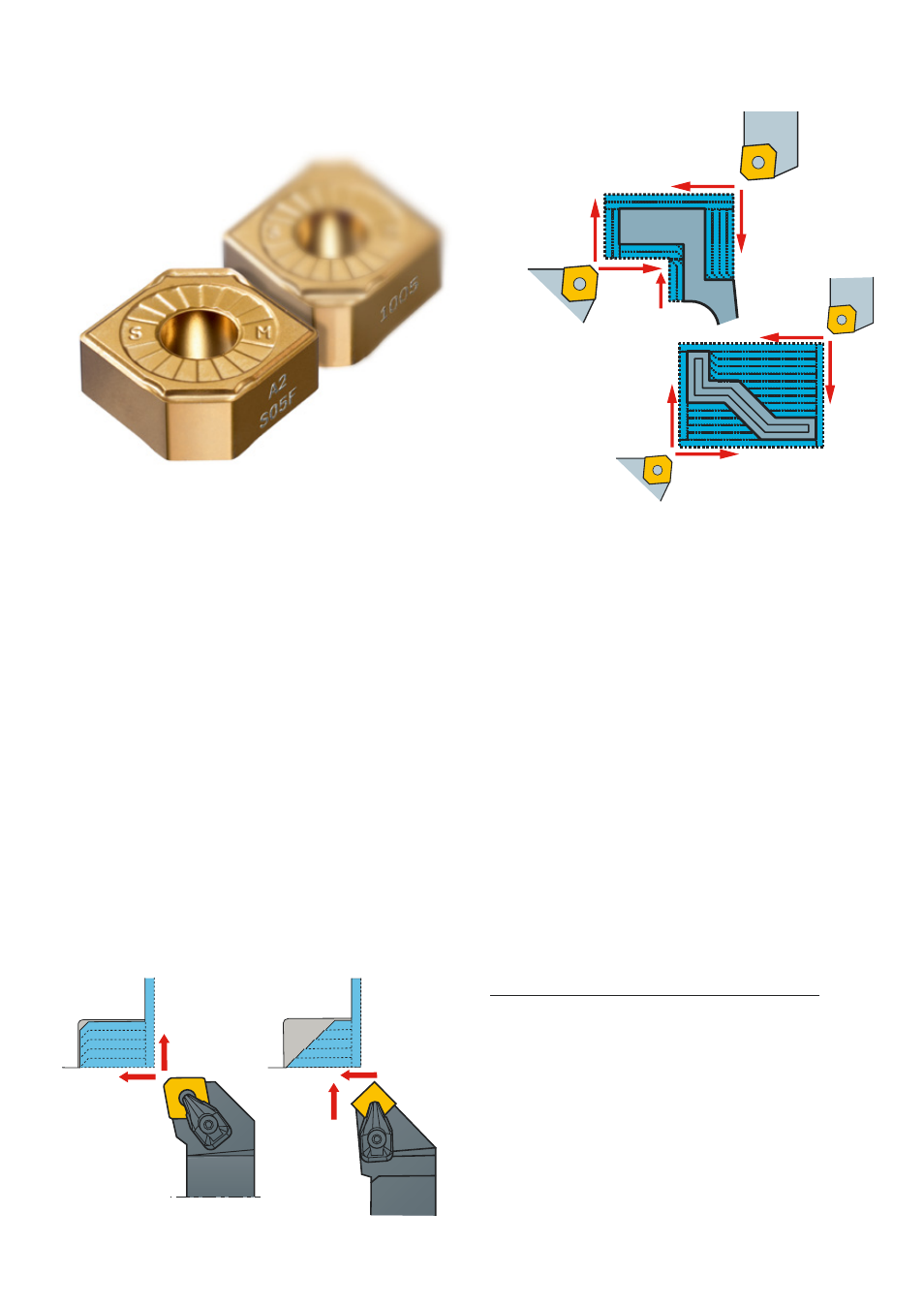

Xcel insert – high productive machining into a corner

A tooling solution for semi-rough turning

into shoulders, combines a host of design

advantages combing the benefits of a

square and rhomboid insert into one single

tool:

• reduced notch wear and increased feeds

compared to rhombic inserts.

• reduced radial forces and constant chip

thickness compared to round inserts.

• greater accessibility in confined spaces

than square inserts, in addition to having

the ability to machine in two directions,

and provide a known offset point for pre-

cise positioning of the cutting edge.

Longer tool life, secure machining, and

increased cutting data – all the best pos-

sible advantages are available from a single

tool.

Two chamfer sizes are available, to suit

depths of cut up to 2.7 mm in intermediate

stage machining, ISM. They are offered in

several grades, all proven performers in ISO

S materials.

Insert code

Max a

p

mm

CNMX 1204A1-SM

1.7

CNMX 1204A2-SM

2.7

C-style CNMX-SM

S-style SNMG

Grade recommendations – first choice

<35 HRC

S05F

>35 HRC

GC1105

Titanium

H13A

Iron based

GC2015

Examples of machining

Casing

Ring