E-pl e-mm m-mm, Coromill®300 – positive round face milling concept, Grade/geometry recommendations for milling hrsa – Sandvik Coromant Heat resistant super alloys User Manual

Page 72

70

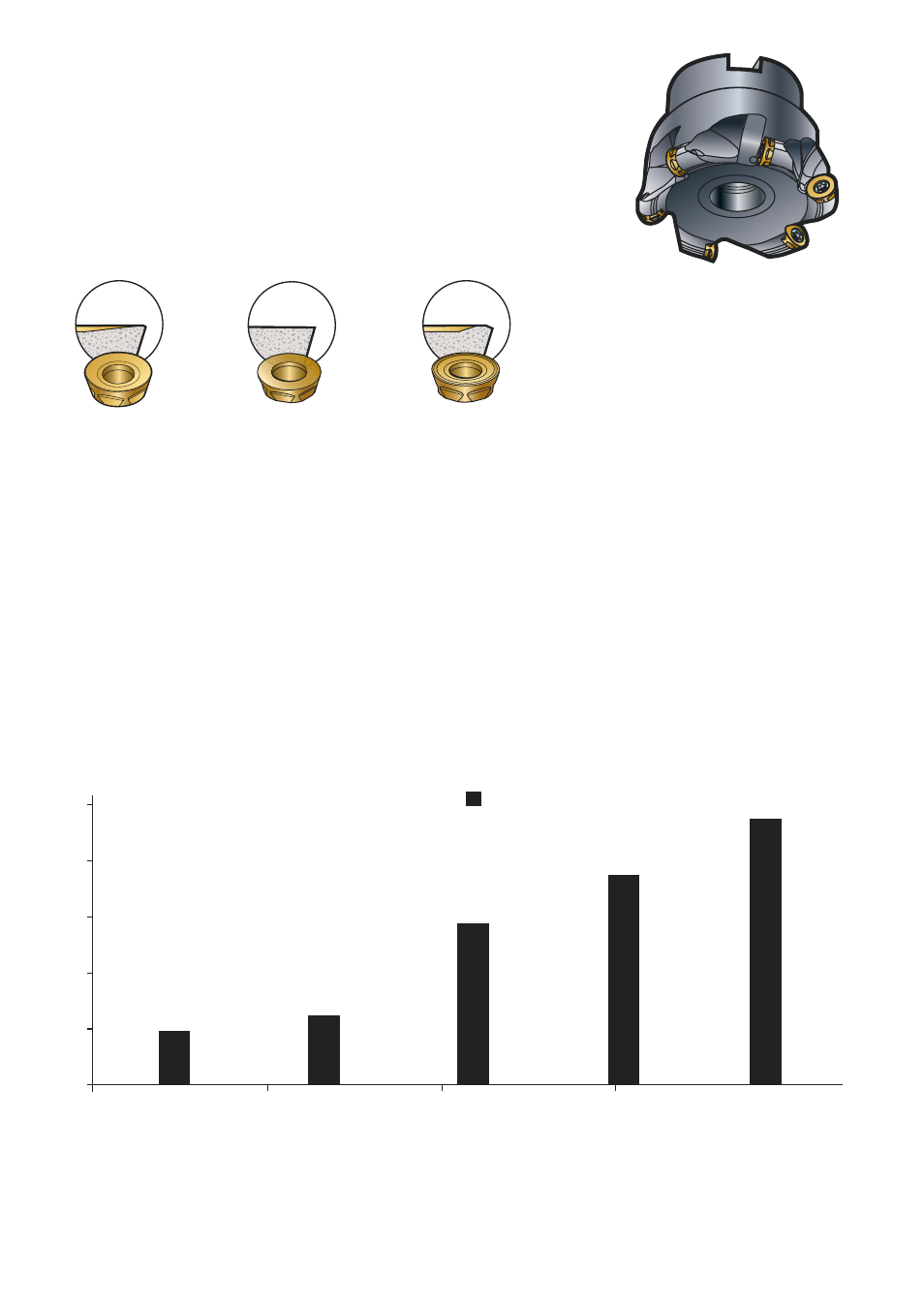

E-PL

E-MM

M-MM

CoroMill® 300

100

80

60

40

20

0

GC2030

S30T

GC2040

S40T

GC1030

R300-1240E-MM

R300-1240E-PL

R300-1240E-MM

R300-1240E-PL

R300-1240E-PM

CoroMill®300 – positive

round face milling concept

Three main geometries are available for

CoroMill 300 cutters when machining HRSA

materials:

High edge sharp-

ness and preci-

sion. Positive

geometry with

edge reinforce-

ment. First choice

with S40T.

High edge sharp-

ness and preci-

sion in combina-

tion with security.

First choice for

applications with

S40T.

Good choice for

general conditions.

Reinforced edge

security in grade

GC2040 compared

to E-PL and E-MM

geometry.

Grade/geometry recommendations for milling HRSA

Tool R300-063Q22-12H

z

n

7, D

c

51 mm, v

c

30 m/min, a

e

36 mm,

a

p

1.5 mm, f

z

0.2 mm/tooth, h

ex

0.12 mm

Material: Inconel 718 (40 HRC)

Minutes in cut

= Average time in cut

Recommendation - longest tool life and highest total of removed metal with the GC1030

E-PM insert.

Good conditions

First choice

Difficult conditions