6 .6 pressure – KROHNE Summit 8800 Vol 2 User Manual

Page 98

98

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

STREAM CONFIGURATION

06

Also the tariff flow totals for all of the 4 levels of volume, mass, energy and CO2 are available for

output to e.g. the printer and the display.

6 .6 Pressure

Liquid

Gas

Steam

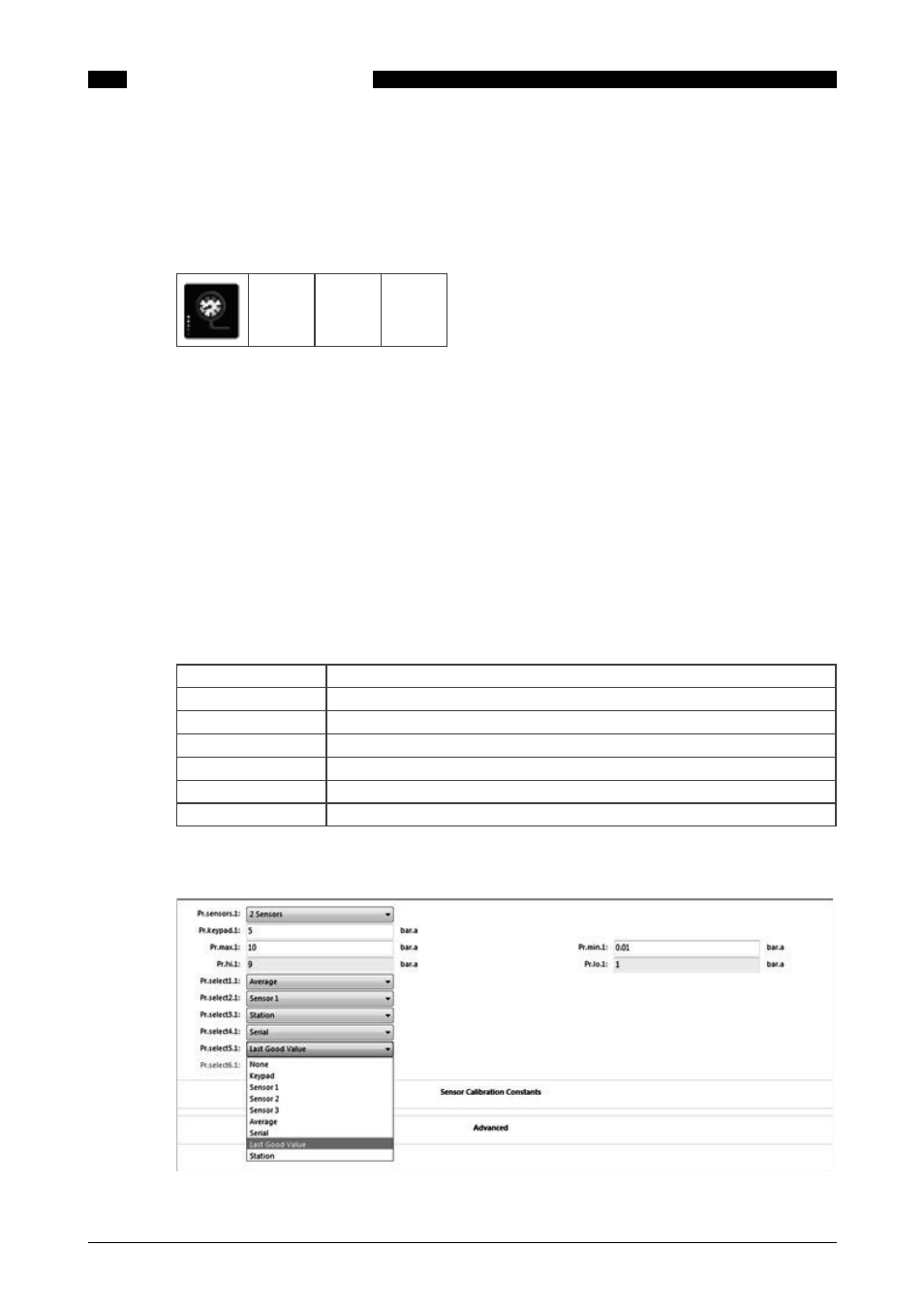

For most corrections, the pressure of the fluid is needed. The SUMMIT has elaborate selection

for multiple pressure sensors and includes error handling when one or more of these sensors

has a problem.

Zero to three pressure sensors can be connected for each stream, with the option to use the av-

erage of these values. It is also possible to use the pressure send via a serial (modbus) link, e.g.

from a SCADA system. In certain applications, there could be no pressure input for the streams,

but only an input for the station. In that case the station pressure could be used by the streams.

This section defines the selection process to arrive to an “in use” value for the pressure. There

are 6 selections in order of priority with each 7 choices. The SUMMIT will start to check the first

selection. If the value is valid (not in alarm) then this selection will be chosen. If not, then the

second selection will be checked etc. The last selection is always the keypad value as defined

earlier, even if all other choices are none.

The 7 choices provided for the pressure selection are:

None

No functionality or transmitter selected, the option will be skipped.

Keypad

The user defined value for this range will be chosen.

Sensor 1-3

The transmitter value, as configure in hardware, will be used.

Average

Average value of all transmitters (selected in DP sensor) will be used.

Serial

Value as sent by Modbus e.g. from a PLC, or smart transmitter will be used.

Last good value

The last good value known before loss of signal will be used.

Station

A pressure as defined under the station/pressure tab

A selection could look like:

Figure 91 Stream pressure selection