5 .2 stream hardware setup – KROHNE Summit 8800 Vol 2 User Manual

Page 59

59

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

HARDWARE DETAILS

05

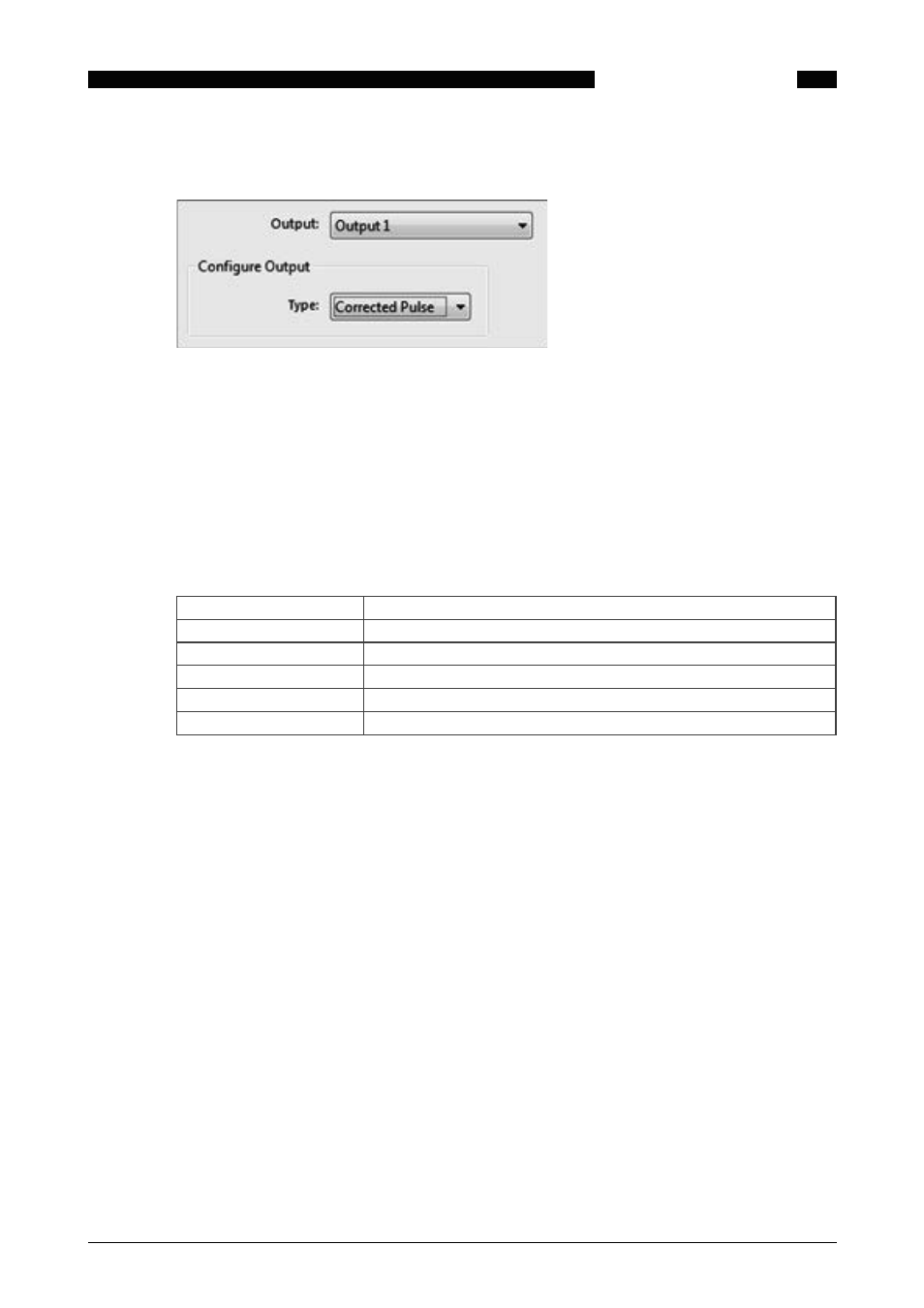

5 .1 .6 .4 Corrected pulse output

Figure 37 Configure corrected pulse output

On output 1 the corrected pulse output can be chosen. If used, the corrected pulse will be send

to the pulse bus, as required in proving applications (see paragraph 10).

5 .1 .7 Serial Output

There is a single non-isolated serial output on all the I/O boards. There are 3 isolated serial

outputs on both Communications boards.

A serial output can be configured to the following functions:

None

No function

Modbus Slave

Modbus slave for reading of Data

Modbus Master

For connection to slave devices, US meter, GC etc.

Printer

For Connection to a Serial Printer.

Encoder

For Turbine meters with smart electronics used for Totals

CTE

For communication protocol

In this volume only the modbus master will be discussed under the next paragraph. Further

details on Serial configuration including printer and report setup can be found in Volume 3.

5 .2 Stream hardware setup

When setting up a meter run, it is important to note, that there are a few basic parameters re-

quired to configure a simple run:

• Flowmeter

• Temperature

• Pressure

• Density/Specific gravity

This section will detail the hardware setup of a stream’s basic parameters.

5 .2 .1 Flowmeters

For metering principle see chapter 3.

5 .2 .1 .1 Pulse

Most meters have one or two pulse outputs (see paragraph 3.1), including:

• Turbine/Positive Displacement flowmeter sometimes also referred to as Rotary meters.

• Ultrasonic flowmeters.