KROHNE Summit 8800 Vol 2 User Manual

Page 162

162

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

SAMPLER

12

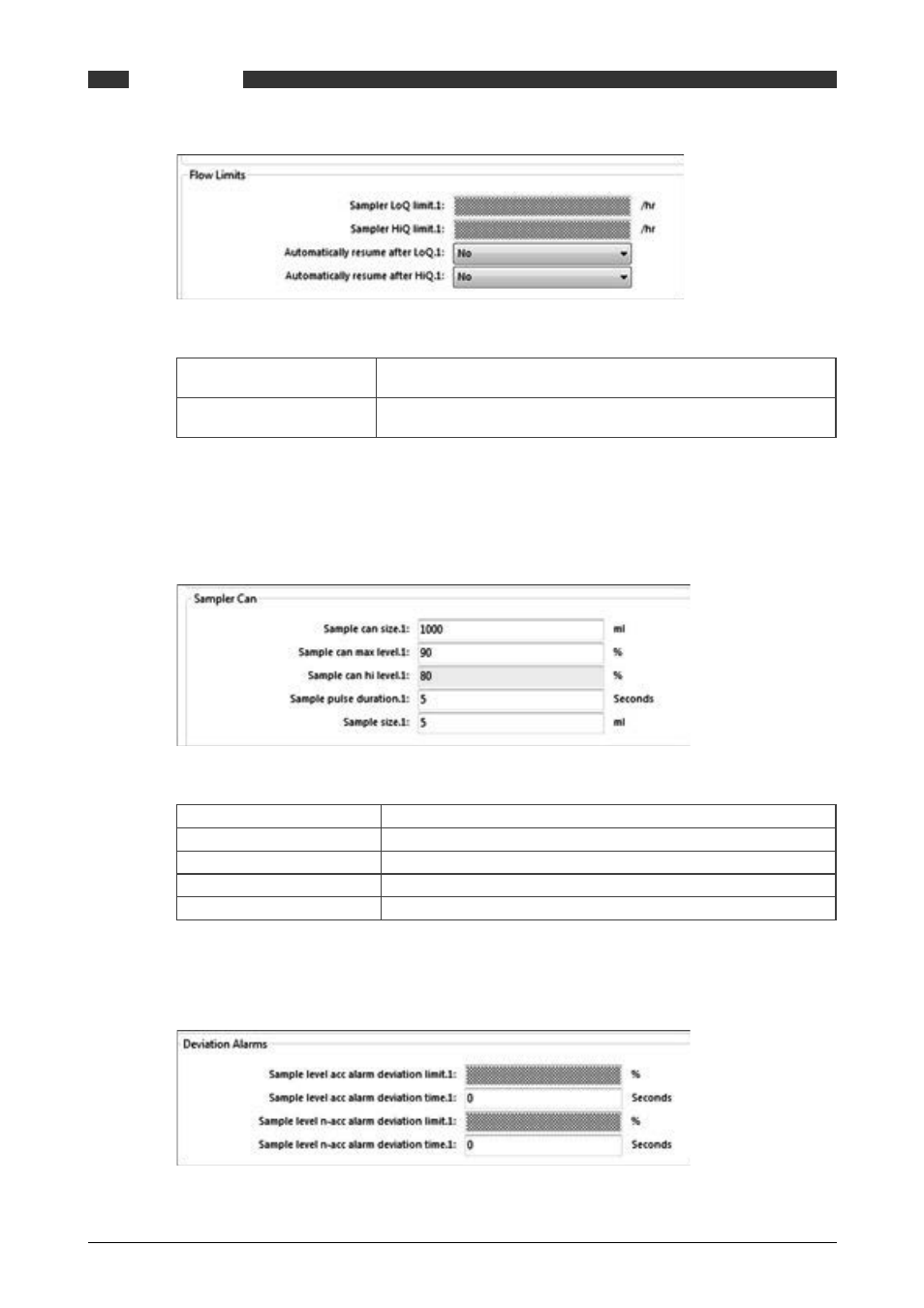

Figure 178 Sampler can flow limits

Sampler low and high flow

limit

Low and high flow limits to stop sampling

Automatically resume after

low and high flow

Restart sampling automatically after returning to normal

Sampler can

Also in case of volume measurement it is important to ensure that the sampler can is not over-

filled. For this reason there is an analog input for the measured can level “can input” in volume

% of full

This is compared to a can level calculated by the sampler, using the following parameters:

Figure 179 Sampler can calculated can level parameters

Sample can size

Can size in ml

Sample can maximum level

Alarm limit can level, in percentage of the ml

Sample can high level

Warning limit level, in percentage of the ml

Sample pulse duration

The time, in seconds, the output will be set to take one sample

Sample size

The quantity of product, in ml, of the sample being captured

Deviation alarms

It is important to verify the proper operation of the sampler. There could for instance be a faulty

valve which would not open or which is leaking. For this reason, there is the option to check for

deviation between the measured and calculated can level:

Figure 180 Sampler can calculated volume % full parameters