11 .3 pid – KROHNE Summit 8800 Vol 2 User Manual

Page 153

153

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

VALVES

11

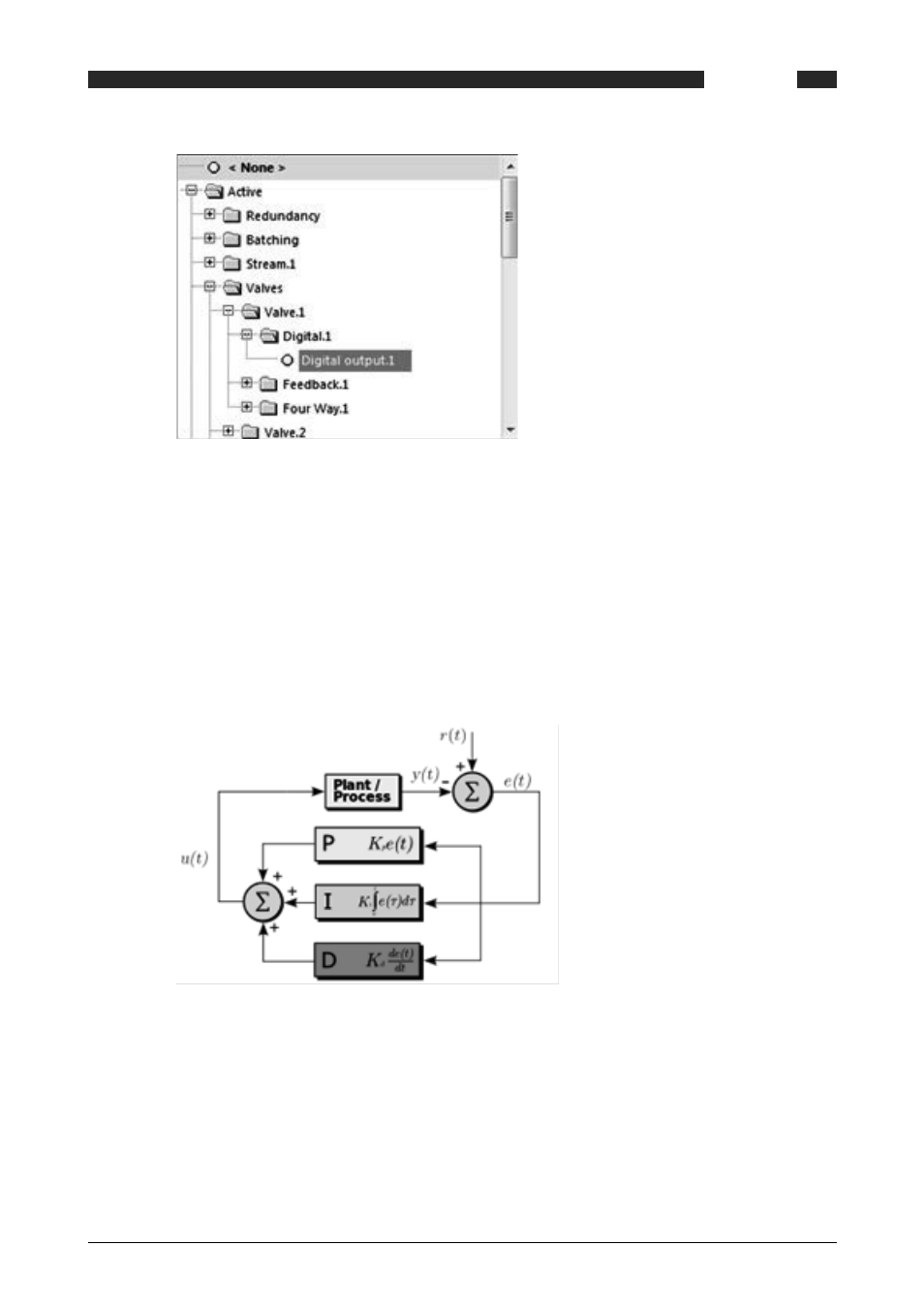

Figure 163 Select the digital valve ID

11 .3 PID

A PID controller (proportional integral derivative) is a closed control loop to steer an output to a

desired value (the setpoint). It uses a feedback system to calculate the difference between the

output and the setpoint. The PID calculation tries to minimize this difference by adjusting the

valve. Important is to set the correct PID parameters to optimize the error and speed.

An analog output will be used to control the valve, either as a direct output value of the PID

algorithm or as a percentage of the maximum value of the PID output. The process value to be

controlled can be any analog value, such as temperature, pressure or flow. The setpoint for the

PID can be controlled viamodbus or via the front panel of the flow computer.

Figure 164 PID control loop

The PID valve has the following parameters:.

- BATCHFLUX 5500 C Quickstart EN (20 pages)

- IFC 050 Converter Quickstart EN (28 pages)

- IFC 100 Converter Quickstart EN (32 pages)

- IFC 300 Converter Quickstart EN (68 pages)

- OPTIFLUX 1000 Quickstart EN (20 pages)

- OPTIFLUX 2000 Quickstart EN (24 pages)

- OPTIFLUX 4000 Quickstart EN (24 pages)

- OPTIFLUX 4040C Quickstart EN (16 pages)

- OPTIFLUX 5000 Flange Quickstart EN (20 pages)

- OPTIFLUX 5000 Sandwich Quickstart EN (20 pages)

- OPTIFLUX 6000 Quickstart EN (28 pages)

- OPTIFLUX 7300 Quickstart EN (24 pages)

- OPTIPROBE Quickstart EN (16 pages)

- TIDALFLUX 2300 F EN (44 pages)

- TIDALFLUX 2300 F Quickstart EN (24 pages)

- WATERFLUX 3000 EN (40 pages)

- WATERFLUX 3000 Quickstart EN (24 pages)

- WATERFLUX 3070 EN (80 pages)

- WATERFLUX 3070 Quickstart EN (32 pages)

- USB ADAPTER PLUS EMF EN (16 pages)

- IFC 050 Converter Modbus EN (20 pages)

- IFC 100 Converter FOUNDATION FIELDBUS EN (64 pages)

- IFC 100 Converter Modbus EN (20 pages)

- IFC 300 Converter FOUNDATION FIELDBUS EN (60 pages)

- IFC 300 Converter HART 0102 EN (20 pages)

- IFC 300 Converter HART 0201 EN (23 pages)

- IFC 300 Converter Modbus EN (24 pages)

- IFC 300 Converter PROFIBUS PA DP EN (40 pages)

- OPTIFLUX 2000-4000 IECEx EN (16 pages)

- OPTIFLUX 2000-4000-5000-6000-7300-IFC 300 Ex EN (40 pages)

- OPTIFLUX 2000-4000-5000-6000 -IFC 100 Ex EN (24 pages)

- OPTIFLUX 4040 C Ex EN (20 pages)

- OPTIFLUX x300 Ex Zone2 EN (1 page)

- H250 M9 ES EN (36 pages)

- VA 40-VA 45 EN (36 pages)

- H250 M10 ATEX II2G Ex d EN (16 pages)

- H250 M10 ATEX II3D Ex t EN (16 pages)

- H250 M40 ATEX II2D Ex t-II2G Ex d EN (20 pages)

- H250 M40 ATEX II2G Ex i EN (20 pages)

- H250 M40 ATEX II3G Ex nA EN (20 pages)

- H250 M40 Ex II2G Reed EN (2 pages)

- H250 M9 ATEX II2G Ex i EN (16 pages)

- H250 M9S ATEX II3D Ex t-II3G Ex nA EN (20 pages)

- M8E Converter HART 0101 EN (13 pages)

- DK 32-DK 34 ATEX II2G Ex i EN (16 pages)