16 .7 pressure correction factor to base, 16 .8 line density, 16 .9 mass flow [t/h – KROHNE Summit 8800 Vol 2 User Manual

Page 182: Bp 1 1 c

182

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

APPENDIX 2: GAS CALCULATIONS

17

K1

API constant [-]

K2

API constant [-]

ρb

Base density [kg/m³]

NOTE:

API constants K0…K2 are set for refined product.

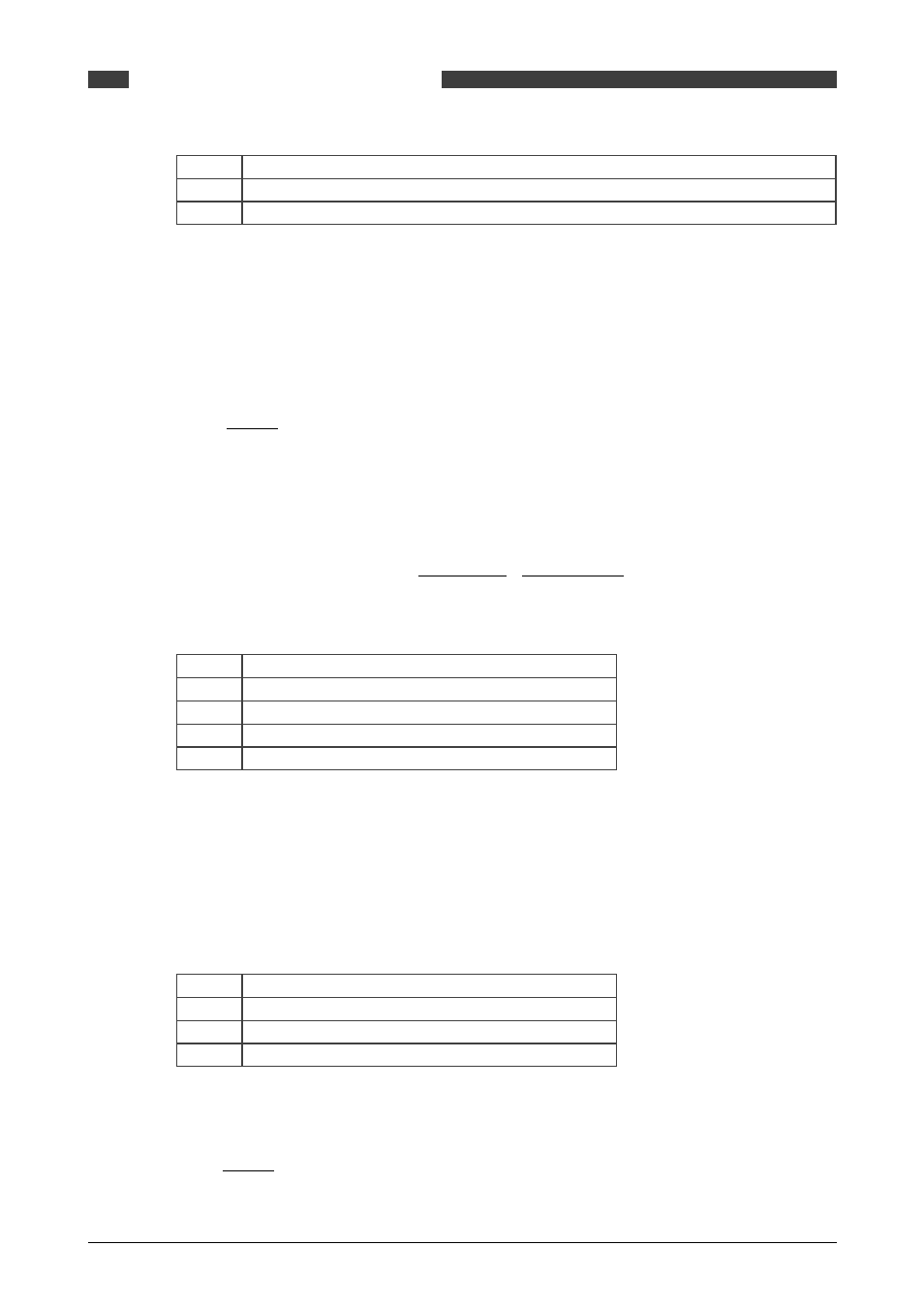

16 .7 Pressure correction factor to base

The pressure correction factor Cpld is calculated by inserting the gauge version of the duty

stream pressure in:

g

pld

b

P

1

1

C

−

=

Equation 16 Liquid pressure correction

Where b is calculated by inserting the duty stream temperature in:

4

2

3

2

6

1

0

*

*

1

0

*

2092

.

4

1

0

*

87096

.

0

*

00021592

.

0

6208

.

1

exp

−

+

+

+

−

=

b

b

T

T

b

ρ

ρ

Equation 17 Liquid compressibility calculation

Cpld

Correction for liquid pressure at the duty stream [-]

Pg

Stream pressure [bar(g)]

b

Oil compressibility factor [1/bar]

T

Duty stream temperature [C]

ρb

Base density [kg/m³]

16 .8 Line density

The flow computer calculates the line density, based on the base density in-use from GC, ac-

cording to the API-2540 standard.

The Line density is then estimated according to:

b

pld

tld

l

C

C

ρ

ρ

*

*

=

Equation 18 API line density

ρb

Base density [kg/m³]

ρl

Fully-corrected line density [kg/m3]

Ctld

Correction for liquid temperature at stream [-]

Cpld

Correction for liquid pressure at the duty stream [-]

16 .9 Mass flow [t/h]

1000

*

l

v

m

q

q

ρ

=

Equation 19 Gross mass flow