6 .2 .4 .1 meter input – KROHNE Summit 8800 Vol 2 User Manual

Page 87

87

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

STREAM CONFIGURATION

06

Meter correction

the correction for expansion of the meter body for pressure and

temperature

Meter information

the identification of the meter

Most Coriolis meters have the option to send the flow data via a serial link and via pulses. In

case pulses are used, then the API level has to be selected. For liquid the pulse input can either

be API 5.5 level A or level B to E, for gas API 5.5 Level B to E only.

API 5.5 Level B to E

for single or dual pulse with the same of different frequencies and pulse

monitoring.

API 5.5 Level A

for dual pulse with pulse correction.

See als chapter 3.1.

6 .2 .4 .1 Meter Input

Define which meter type or manufacturer is applicable along with the associated parameters

associated with the meter.

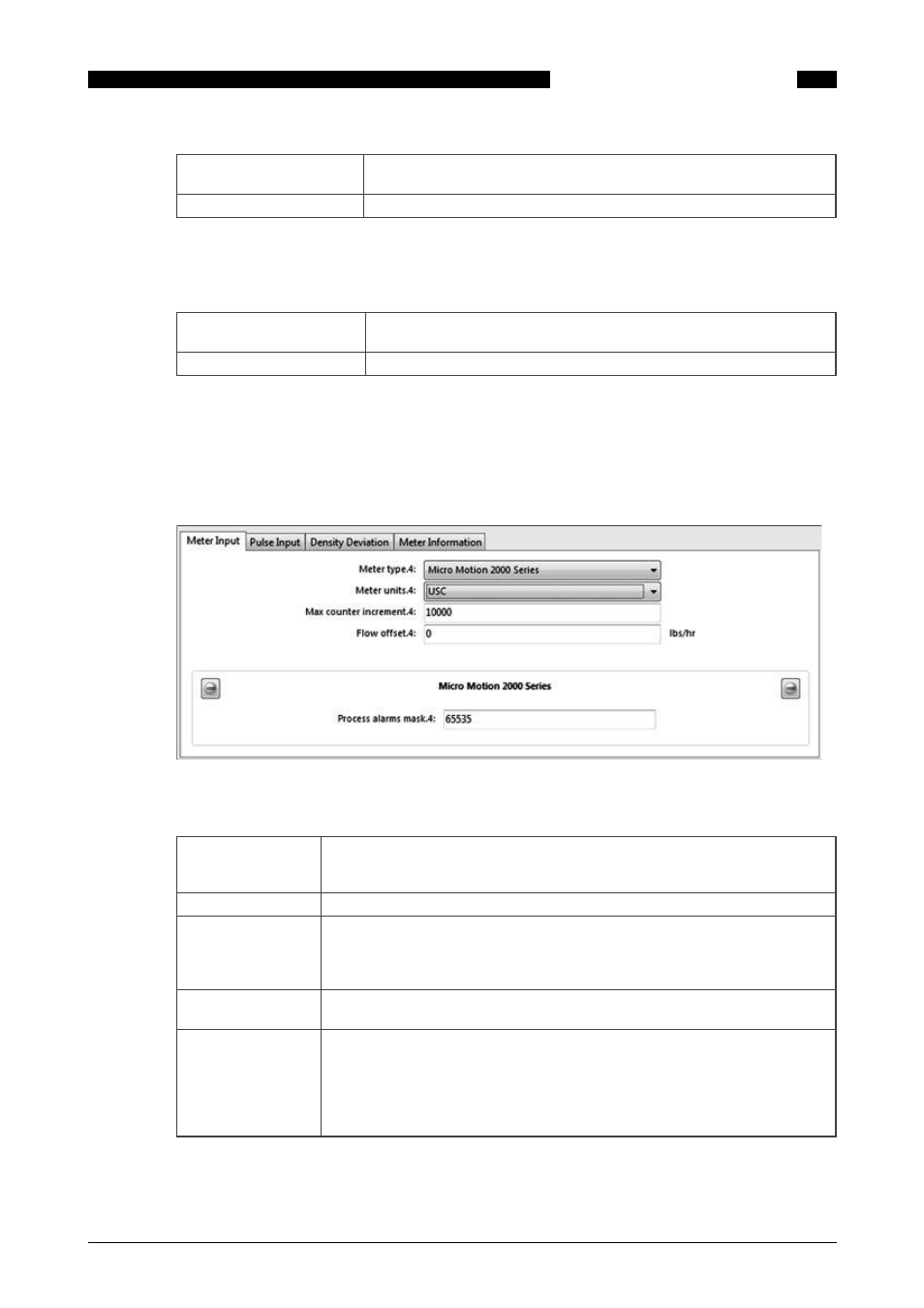

Figure 78 Example Coriolis meter input section

Meter type

The specific meter to be used can be selected from a list. As meters are generally

designed for liquid, gas or stream, the list varies depending on the medium. Also

there is the option to use an analog input for flow.

Meter units

The engineering units in which the meter is measuring flow.

Maximum Counter

Increment

The maximum allowable increment for the flow data counter used for the

calculated volume. Used when the meter communicates serially. This prevents

a massive increment when, after a communication failure, the meter resumes

normal communication.

Flow offset

This is used to simulate flow during testing when no meter is available. In theorie

it could also be used to correct a fixed mis-match of the flow.

Meter specific data

For certain meters some parameters must be set. As these parameters are

meter specific, please consult the meter manufacturer’s operating instructions

for further guidance. Parameters for the following meters are available:

- KROHNE MFC010 (liquid)

- Micro Motion 2000 Series (liquid)

- Proline Promass 84 (gas)