6 .2 .2 .4 meter correction – KROHNE Summit 8800 Vol 2 User Manual

Page 79

79

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

STREAM CONFIGURATION

06

Dual frequency deviation

The threshold value (+/-) for the deviation of the two frequencies

above which an alarm is raised.

Dual frequency pulse limit

Used to monitor pulse fidelity to alarm an added or missing

pulse caused by electrical transients and electronic failures. This

monitoring function allows the user to reduce the flowmeter

uncertainty factors.

Dual frequency pulse interval

The time between pulses sequences. This is the maximum allowable

time for pulse limits before an alarm is activated.

Dual frequency failure limit

Lack of continual pulses before the meter is deemed failed and

raises an alarm

Dual frequency direction change

Number of pulses allowed in opposite flow to determine the

direction of the medium flowing in the meter.

Dual frequency min. frequency

Low cut-off frequency. This is frequency below which the flow will be

considered 0.

6 .2 .2 .4 Meter Correction

Define the correction for expansion of the meter body for pressure and temperature to maximize

the ultrasonic meter accuracy as the properties of the UFM, and it’s connection to the main

stream pipe may change.

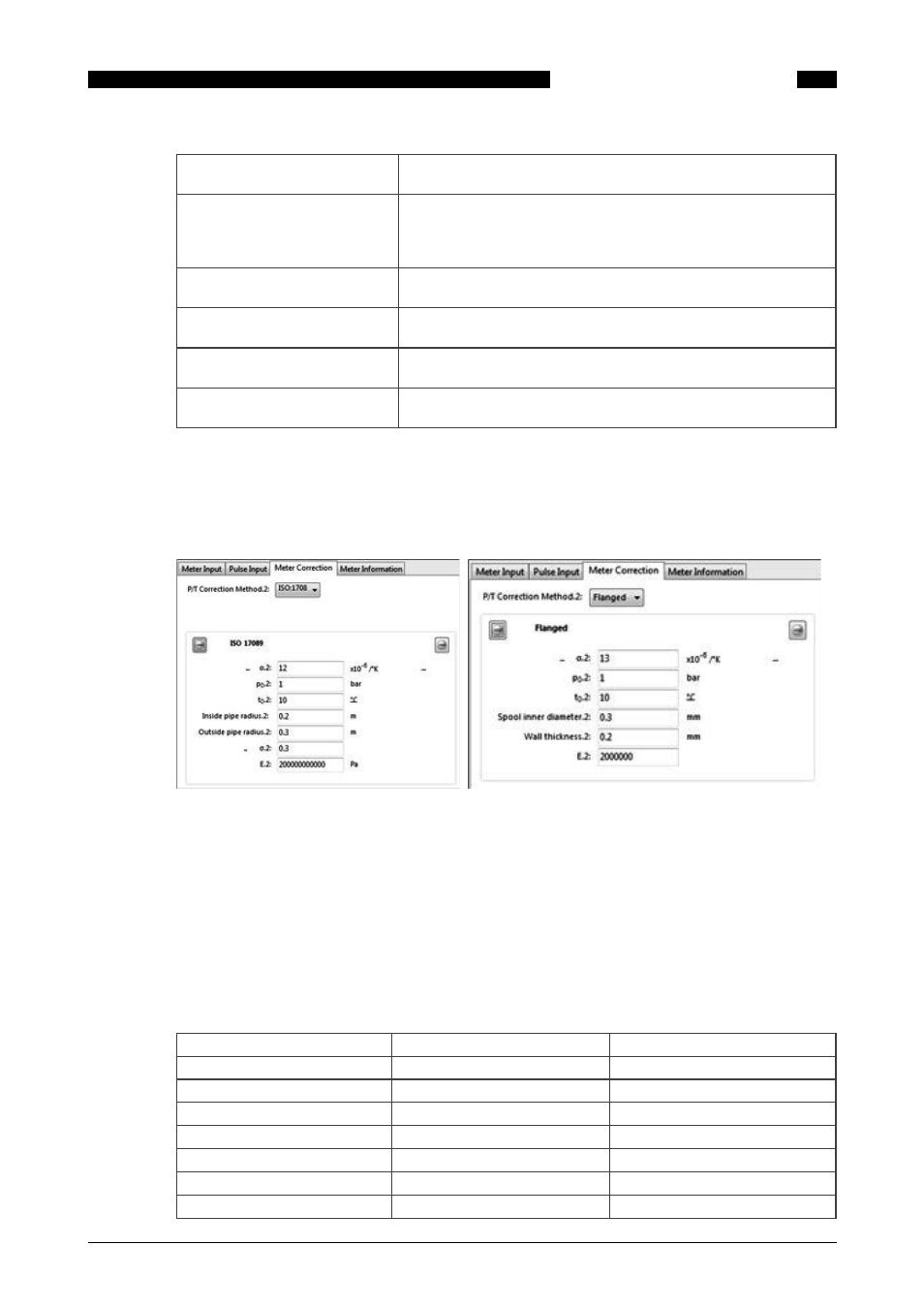

Figure 71 Examples ultrasonic meter correction section

Selection of any Pressure or Temperature expansion correction:

• None

• Correction for Flanged

• Correction for Welded

• Correction in accordance with ISO 17089

• Cryogenic

With as parameters:

Flanged & Welded

ISO 17089

Cryogenic

Thermal expansion, α

Thermal expansion, α

NIST constants A to E

Reference pressure, p0

Reference pressure, p0

Reference temperature, t0

Reference temperature, t0

Spool piece inner diameter

Inside pipe radius

Wall thickness

Outside pipe radius

Modulus of elasticity, E

UFM poison ratio, σ

Modulus of elasticity, E