3 .2 ultrasonic meters – KROHNE Summit 8800 Vol 2 User Manual

Page 22

22

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

METERING PRINCIPLES

03

• A second lower frequency pulse, so a combination of HF with MF or LF. Off course the fre-

quency ratio or blade ratio between the two pulses must be given.

API has a classification on the quality actions taken on the pulses:

API level E is achieved solely by correctly applied

transmission systems, criteria and recommended

installed apparatus of good quality.

Basically a non-issue for flow computers

API level D system consists of manual error

monitoring at methods of comparison, as used in

Levels A through D.

This means: Only 1 pulse is needed on the flow

computer.

API level C consists of automatic error monitoring

for number, frequency, phase, and sequence and

error indication at specified intervals.

This means: two pulses must be installed: the

meter pulse and monitor pulse, which may be of

different frequency (see frequency ratio)

API level B consists of continuous monitoring, with

an error indication under all circumstances when

impaired pulses occur.

This means two pulses of the same frequency

must be installed: the meter and monitor pulse.

API level A: consists of continuous verification and

correction given by the comparator.

The major issue here is; the flow computer has

to correct when a wrong pulse occurs. This is

quite advanced and is fully implemented in the

SUMMIT.

Nowadays more and more electronics is incorporated into the meters, such as in ultrasonic

and Coriolis meters. These meters normally emulate two high frequency pulses, to make them

look the same as rotating meters from the installation standpoint. The flow is calculated and a

special pulse output is driven by the processor. Although the need for a second output pulse is

diminished, most meters still carry them. API Level A is not really required.

There are also meters with smart indexes. Here the indexes values itself can be read by the

flow computer. The advantage is that the totals on the meters index are identical to the flow

computer totals. Also, if the flow computer is replaced, the total will be automatically read. The

communication is then digital and can be read via the serial port.

3 .2 Ultrasonic meters

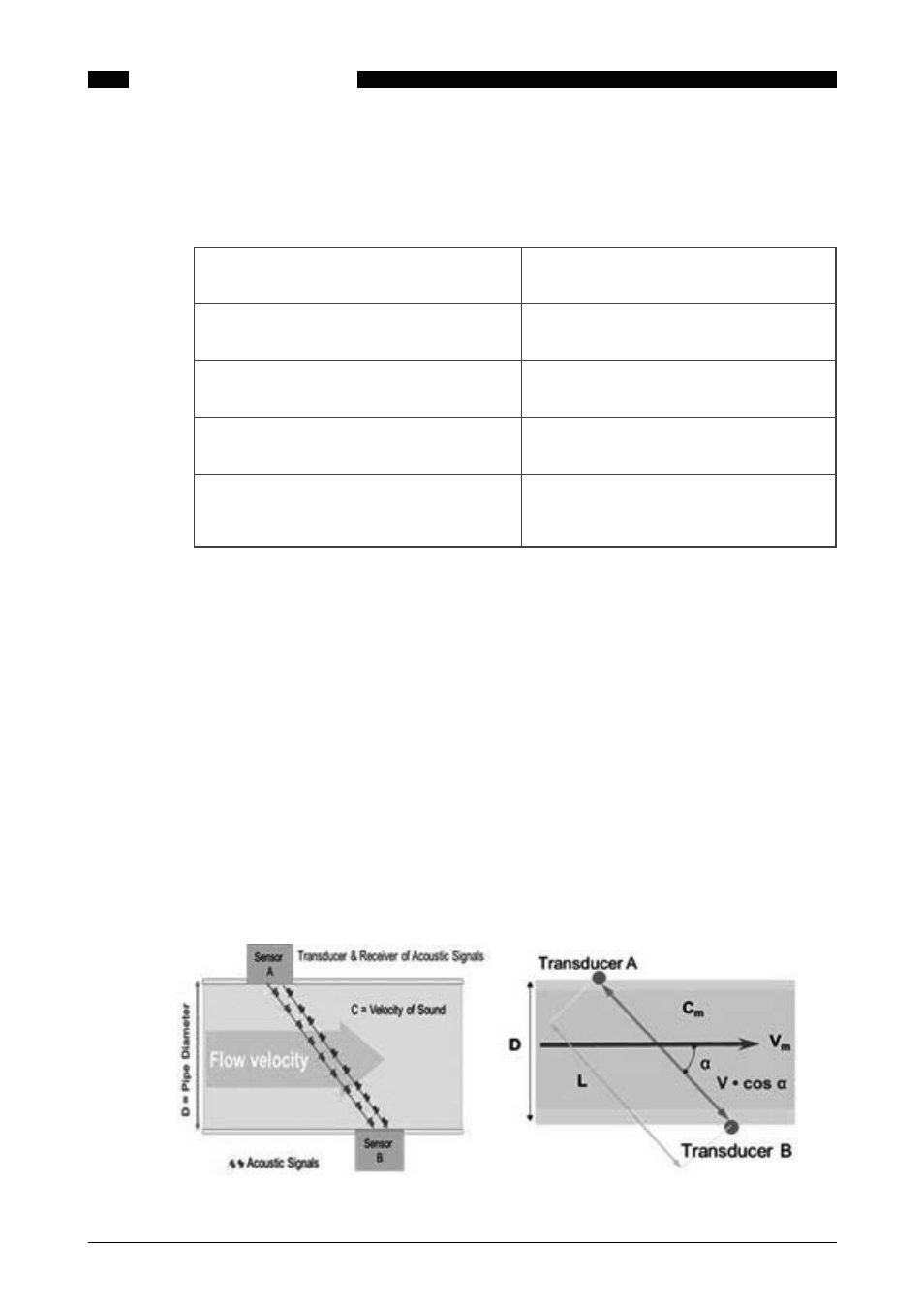

Ultrasonic meters are based on Transit Time Measurement of high frequency acoustic signals.

These signals are transmitted and received along a diagonal measuring path.

A sound wave going downstream with the flow travels faster than a sound wave going upstream

against the flow. The difference in transit time is directly proportional to the flow velocity of

the liquid or gas. This can be compared with the speed a canoe travels upstream compared to

downstream.

Figure 3 Ultrasonic measurement principle