16 .4 low flow cut-off control, 16 .5 retrieve base density, 16 .6 temperature correction factor to base – KROHNE Summit 8800 Vol 2 User Manual

Page 181

181

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

APPENDIX 2: LIQUID CALCULATIONS

16

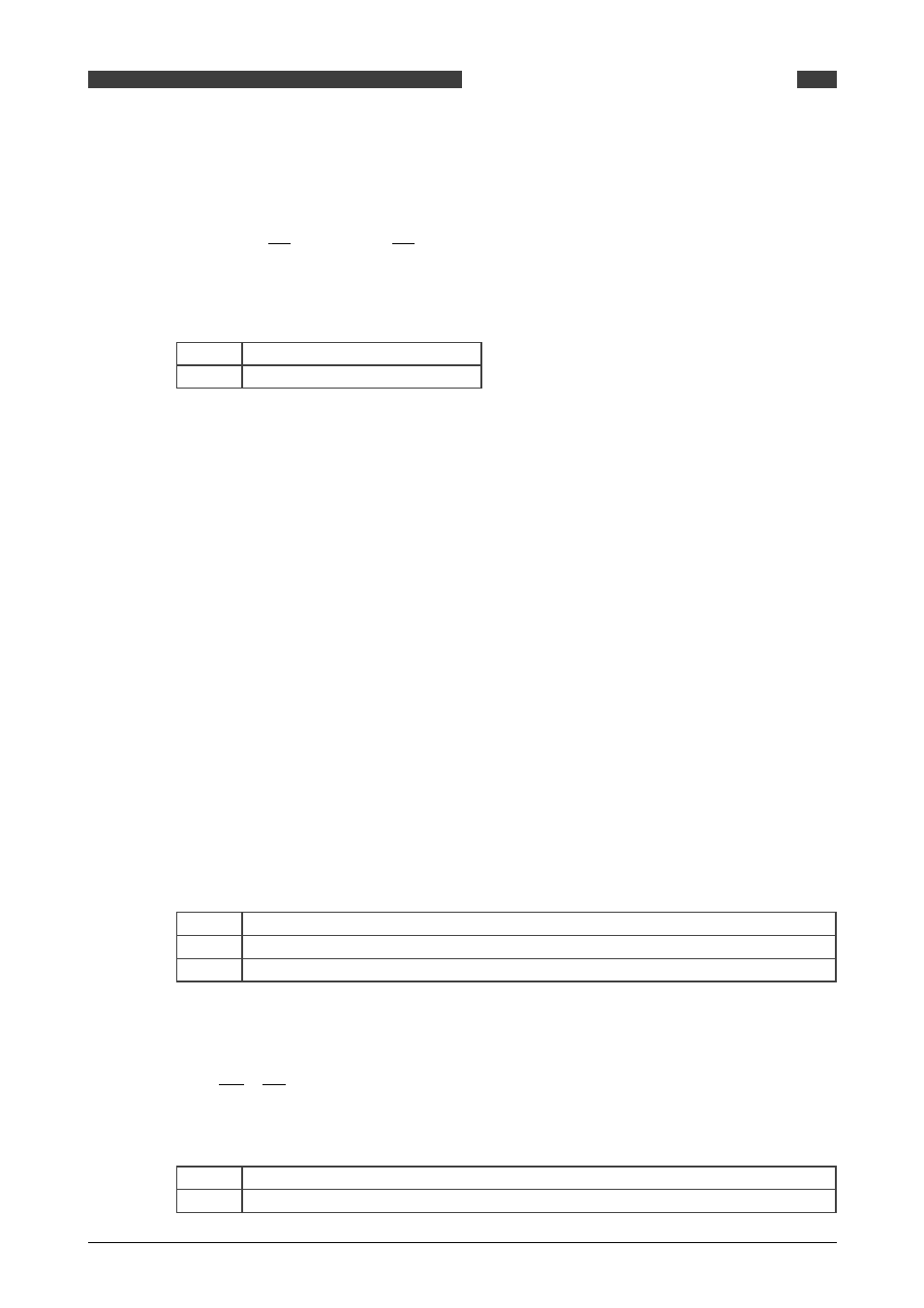

3) For both directions the volume flow rate is corrected as follows:

max

0

1

0

1

*

*

re

bodypressu

atur

bodytemper

line

bc

Q

Q

Q

Q

q

q

=

Equation 12 Bi-directional volume flow rate

Where:

qbt

Corrected volume flow [m3/hr]

qline

Uncorrected volume flow [m3/hr]

16 .4 Low flow cut-off control

The low flow cut-off, entered in m³/h, determines whether the stream status is on-line or off-

line. As well as controlling the display status, this limit determines whether the stream can be

considered ‘non-flowing’ to enter or leave maintenance mode. The default value is around the

+/- 1%. Environment conditions may have an influence on this setting.

16 .5 Retrieve base density

The flow computer receives the base density from a keypad value of 1050kg/m3 at base condi-

tions.

16 .6 Temperature correction factor to base

The temperature correction factor to standard temperature is calculated by inserting the duty

stream temperature in:

)

T

-

(

=

std

T

T

∆

Equation 13 Delta temperature base correction

Followed by:

(

)

[

]

T

8

.

0

1

T

exp

C

b

b

tld

∆

α

+

∆

α

−

=

Equation 14 Liquid temperature correction

Ctld

Correction for liquid temperature at stream [-]

αb

Oil thermal expansion coefficient at standard temperature [1/°C]

ΔT

Temperature difference from standard temperature [°C]

For the first iteration, the line density is inserted for αb in the equation below. After this, the

value of αb from the previous iteration is used:

2

1

2

0

K

K

K

b

b

b

+

+

=

ρ

ρ

α

Equation 15 Liquid thermal expansion

αb

Oil thermal expansion coefficient at standard temperature [1/C]

K0

API constant [-]