13 .1 general – KROHNE Summit 8800 Vol 2 User Manual

Page 168

168

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

BATCHING

13

.

13. Batching

Liquid

Gas

Steam

In the oil industry one and the same pipes is often used to transport different products one after

the other, or batch by batch. The process to do so is called batching and is used for:

• Pipeline transfer, e.g. to refineries

• Drum filling

• Truck, train and ship loading

• Mixing applications

The SUMMIT 8800 has 5 independent batching functions for each stream plus one station batch-

ing. Batching can be continuous, until an manual or automatic switch to a new batch occurs.

Batching can also be based on transfer of a fixed volume or mass after which the batch stops,

e.g. in filling applications.

For the configuration, see the next chapters.

13 .1 General

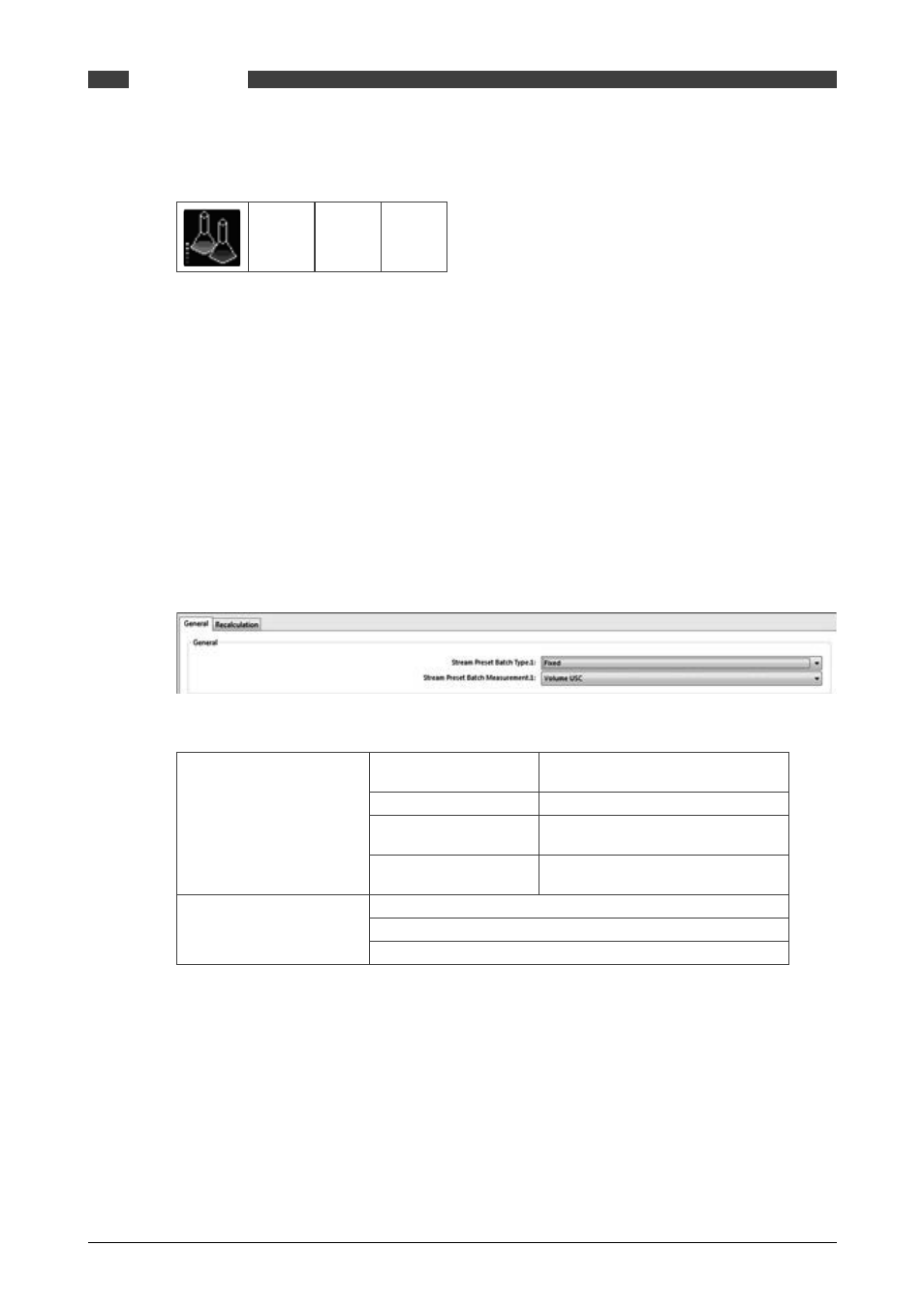

Figure 188 Batching general selection

Preset batch type

The method used for

batching:

Explanation

None

No batching used

Fixed

Batching based on fixed quantity to be

transported

Continuous

Continuous batching, flowing until an

event occurs

Preset batch measurement

Volume or mass batch based measurements

Volume USC or Metric

Mass USC or metric

Fixed batch information

For fixed batching it is often wise to slowly open and close the valve to prevent hammering, dam-

aging the pipe or meter. For this a PID flow control valve is used to ramp up and down. On top

of this often a preload is used to fill the pipe and an afterload is used to be able to stop the flow

accurately. This gives a following diagram: