12 .1 sampler method – KROHNE Summit 8800 Vol 2 User Manual

Page 160

160

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

SAMPLER

12

12. Sampler

Liquid

Gas

Steam

For many applications it is necessary to monitor the quality or composition of the fluid going

through the pipe. One of the ways to do so is to regularly collect a sample of fluid in a can or

container and to take this to a laboratory analysis. The associated standards are the

ISO 3171, 1998, chapter 15

for the sample volume

API 8.2 appendix F

for the sample frequency, grab factor, performance factor etc.

In many cases only one sampler will be used for the station, but where multiple products are

used multiple samplers might be needed. The SUMMIT can handle one sampler per stream.

In case of mass based sampling, the SUMMIT can handle two cans per sampler. The switching of

cans has to be done manually, monitoring of the weight is done automatically, including tarring

for bottle weight.

Many different methods are supported by the flow computer and have been devised to get the

most relevant sample for an application. This varies on the sampler method (which period to

take the sample) and the sampler frequency (how often to take a sample):

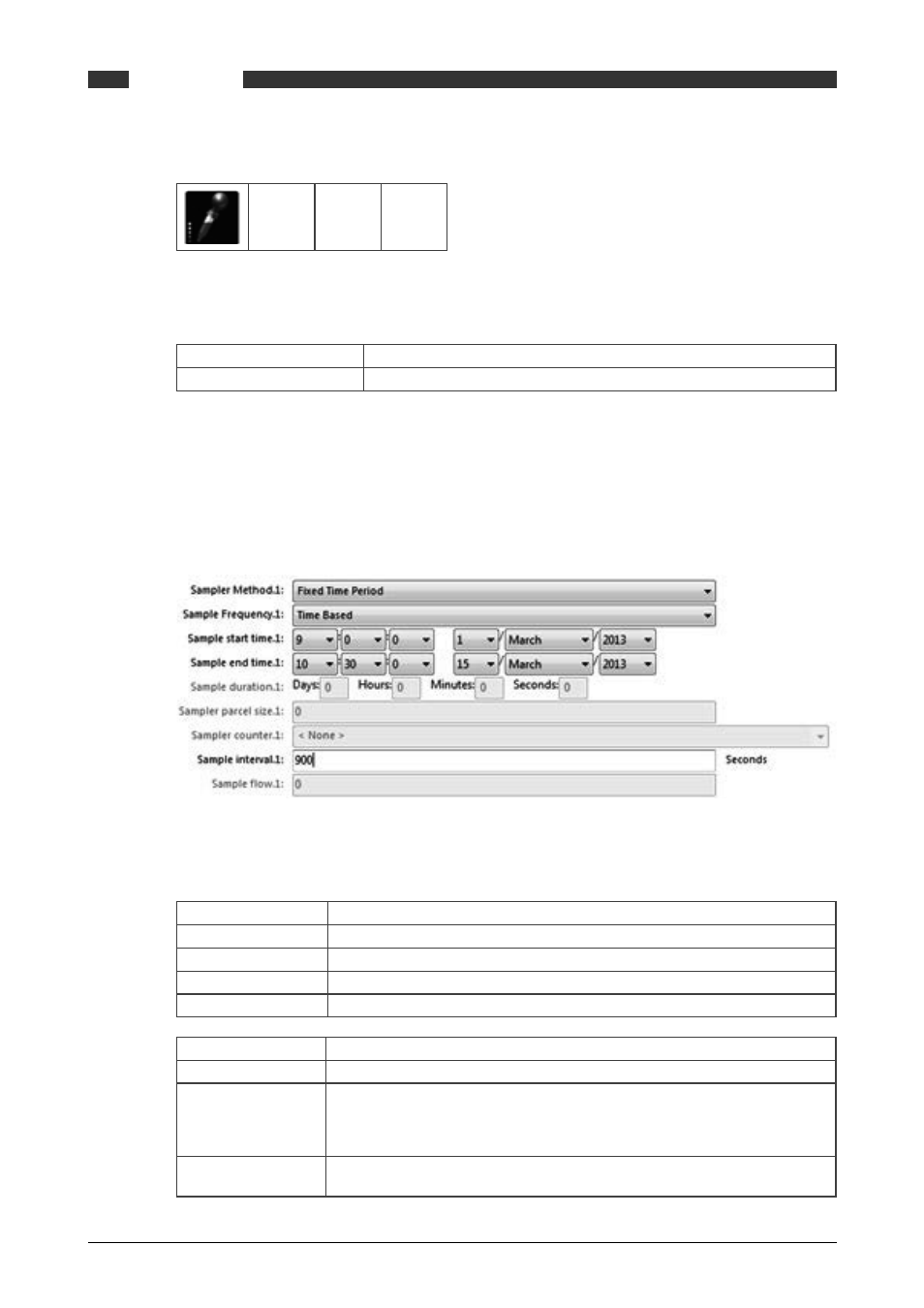

Figure 175 Sampler timed based configuration

12 .1 Sampler method

Off

No sample is taken

Fixed time period

Sampling is activated from the start date/time to an end date/time

Duration

Sampling is actived for a fixed duration in days to seconds

Batch

Sampling is is based on the batch parcel size

Continuous

Sampling is always running

Sample frequency

Time based

A sample will be taken periodically. The interval in seconds must be given

Flow based

A sample will be taken every time when a quantity of product has passed.

In this case the ID must be selected from any of the available counter

increments of volume, mass or energy (see below) and the quantity is defined as

the flow passed.

Manual

A sample will be taken when manually triggered, or a request received via a

modbus