KROHNE Summit 8800 Vol 2 User Manual

Page 23

23

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

METERING PRINCIPLES

03

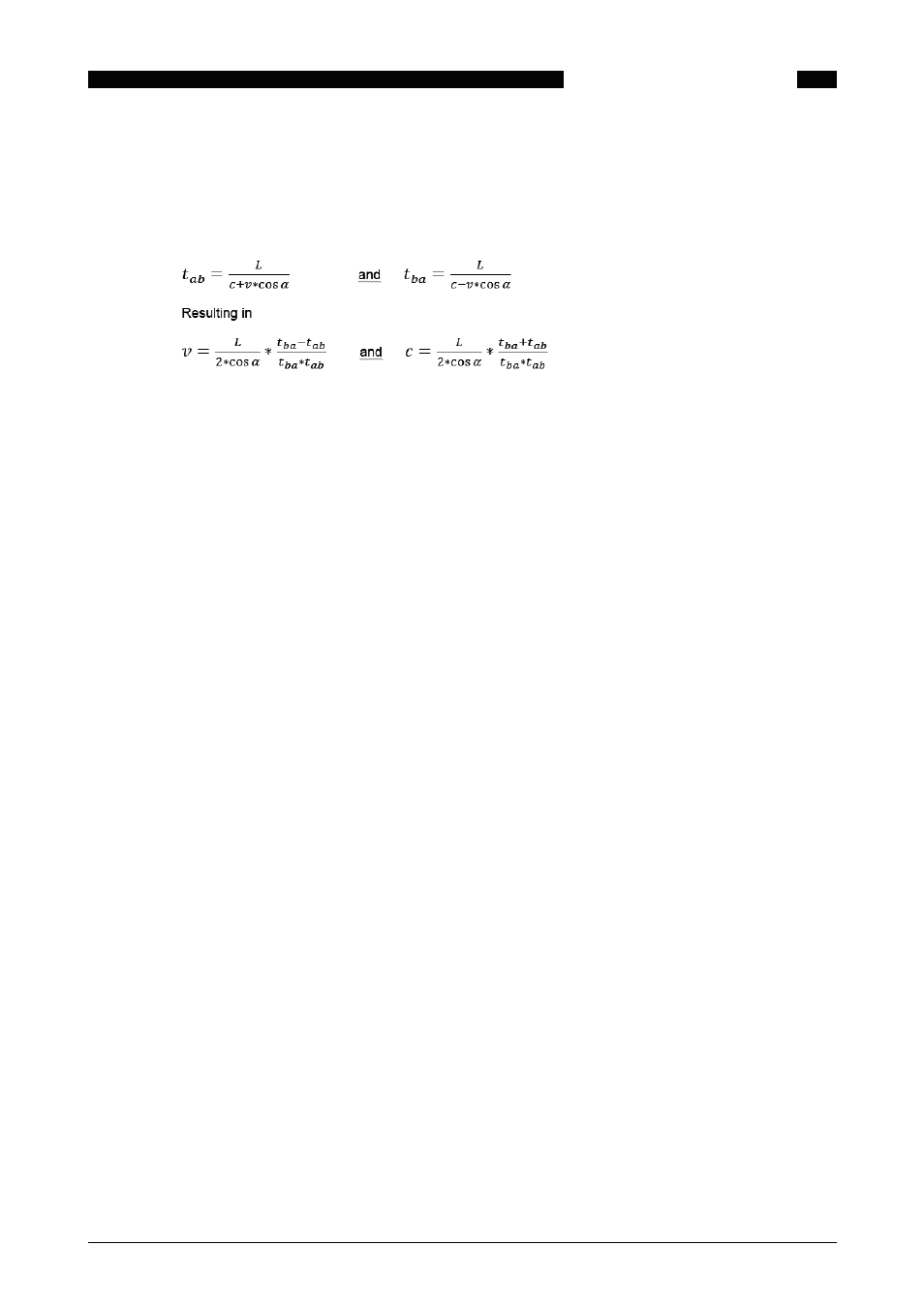

Mathematically, the time to transmit from a to b and back depends on the distance (L) between

the two transducers, the speeds of the medium (v) and sound (c) plus the angle of the path (α) as

follows:

Equation 1 Ultrasonic measurement formulae

With the velocity of the gas and the area of the pipe, the volume flow rate can be calculated.

The problem is however that the oil or gas is not always equally distributed through the pipe.

The flow normally is faster in the centre than in at the pipe and has a certain profile depending

on turbulent or laminar flow. So you do need the proper average velocity over the complete pipe.

With single beam meters, such as clamp-on meters, the accuracy is therefore very limited.

That is why the medium must be measured at different locations in the pipe. The trick is to best

estimate the profile/ the average flow. All manufacturers come up with different arrangements

in multi-path meters.

The output of ultrasonic meters is normally a combination of a dual pulse and a serial link.

• The dual pulse is generated by the electronics to emulate a turbine meter but does not pro-

vide its diagnostics.

• The serial link has typically a modbus protocol specific to the manufacturer, but for Instromet

there is also the proprietary “Instromet protocol”. This serial protocol carries the flow rate,

but also meter diagnostics. For that reason in many cases both links are used at the same

time.

Each manufacturer has its own set of diagnostics. Typical diagnostics are:

• The amplification needed to send a signal between the transducers, both up- and down-

stream

• The signal to noise ratio at each transmitter

• The speed of sound measured by each path or ratio’s between them

• An indication of the type of flow profile

For gas there is an interesting additional diagnostics which is the calculated against the meas-

ured speed of sound based on AGA 10. The meter calculates besides the speed of the gas also

the speed of sound. AGA 10 gives the formula from which the speed of sound can be calculated

from the composition, the temperature and the pressure. Off course the measured and calcu-

lated speed of sound should be equal. If not one of the variables (meter, chromatograph or P or

T) must be wrong or badly calibrated. This is therefore a perfect over all metering system check.

3 .3 Differential pressure (dP) meters: e .g . orifice, venturi and cone meter

Differential pressure flowmeters use the Bernoulli’s rule to measure the volume flow of gas

or liquid in a pipe. They use a restriction in a pipe to measure the volume as it creates a differ-

ence in pressure before and after the restriction. The pressure difference (∆p) increases as flow

increases.