6 .2 .1 .3 meter information, 6 .2 .2 ultrasonic – KROHNE Summit 8800 Vol 2 User Manual

Page 75

75

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

STREAM CONFIGURATION

06

Turbine type

API 5.5 level A.

Turbine frequency offset

An offset to be added to the input frequency. Ideal for testing purpose:

even when no input is available, a frequency can be set to simulate an

input. Make sure that in normal mode the offset is 0.

Turbine frequency deviation

The threshold value (+/-) for the deviation of the two frequencies above

which an alarm is raised.

Turbine pulse limit

Used to monitor pulse fidelity to alarm an added or missing pulse caused

by electrical transients and electronic failures. This monitoring function

allows the user to reduce the flowmeter uncertainty factors.

Turbine pulse interval

The time between pulses sequences. This is the maximum allowable time

for pulse limits before an alarm is activated.

Turbine failure limit

Lack of continual pulses before the meter is deemed failed and raises an

alarm

Turbine direction change

Number of pulses allowed in opposite flow to determine the direction of

the medium flowing in the meter.

Turbine minimum frequency Low cut-off frequency. This is frequency below which the flow will be

considered 0.

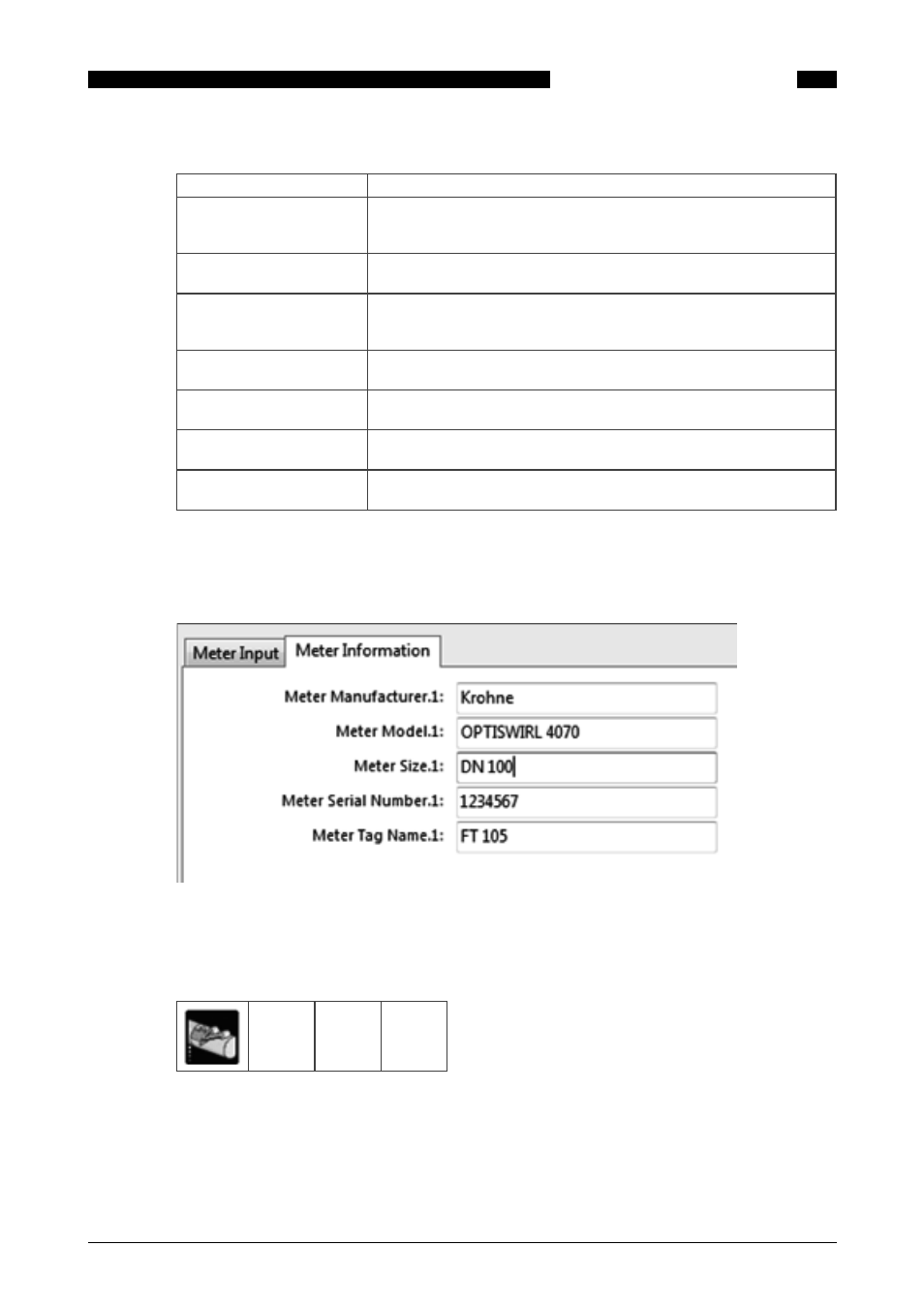

6 .2 .1 .3 Meter information

For each meter information to identify the meter can be enetered. This can be usefull as identi-

fier text on the screen or to send to a supervisory system in a system.

Figure 67 Define meter information

6 .2 .2 Ultrasonic

Liquid

Gas

Steam

Please refer to chapter 4.2 for metering principles of ultrasonic meters.

Four setup sections available to configure an ultrasonic flowmeter: