3 .7 gas normalisation – KROHNE Summit 8800 Vol 2 User Manual

Page 30

30

www.krohne.com

08/2013 - MA SUMMIT 8800 Vol2 R02 en

SUMMIT 8800

METERING PRINCIPLES

03

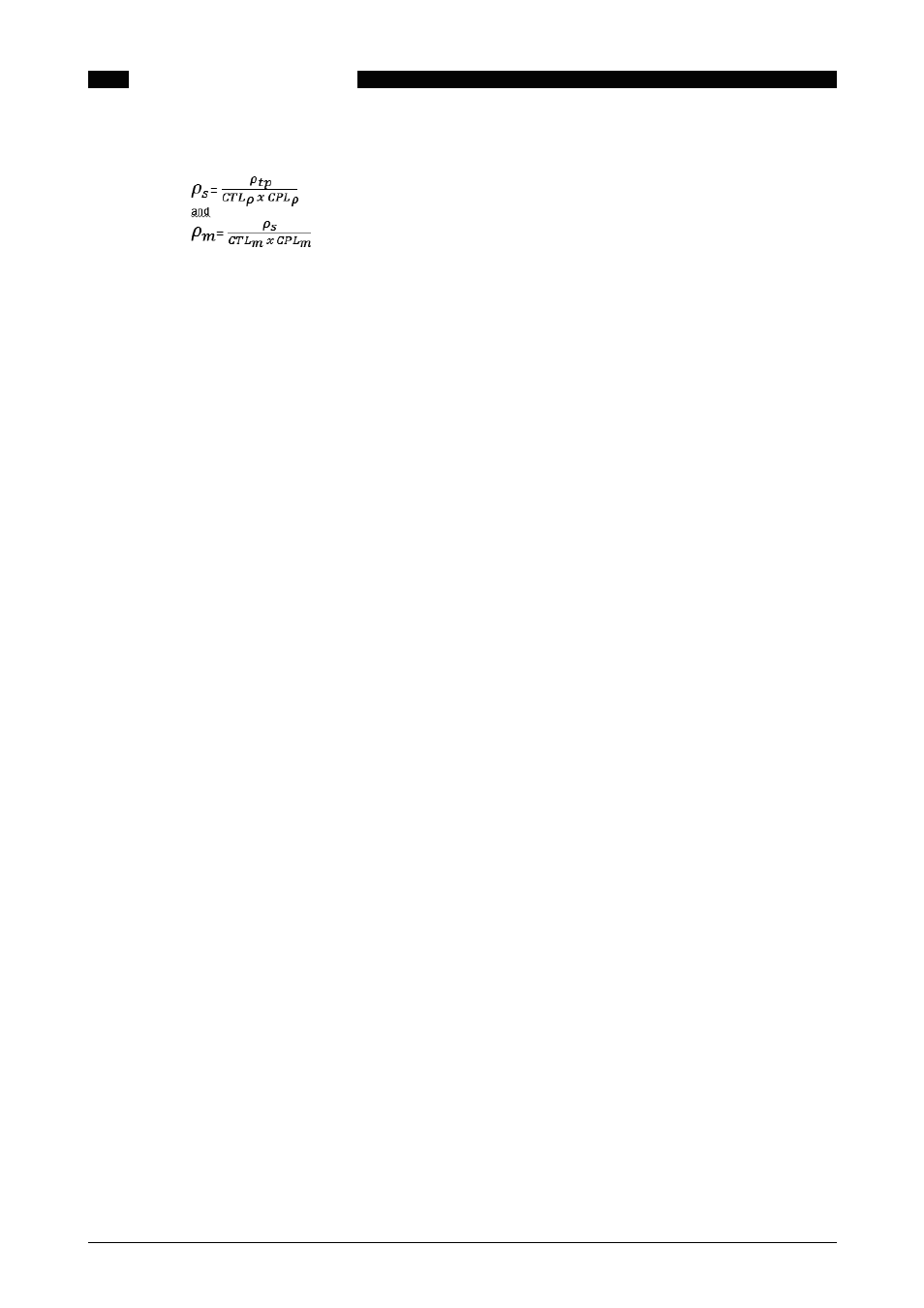

The following formula applies:

Where

ρm

Line density of the liquid at metering conditions in kg/m3 or lbs/ft3

ρtp

Line density of the liquid corrected for temperature and pressure in kg/m3 or lbs/ft3

ρs Standard Density of Liquid in kg/m3 or lbs/ft3

CTLρ :

Temperature correction factor density at density test point

CPLρ :

Pressure correction factor density at density test point

CTLm :

Temperature correction factor at the meter

CPLm :

Pressure correction factor at the meter

Several different calculations, depending on the type of product, are available to determine the

correction factors.

3 .6 .1 Mass and energy

The mass and energy can be calculated from the volume (or the volume from the mass) using:

Mass flow rate:

qm= qbc* ρm

Energy flow rate:

qe= qn* Hs

Where Hs is the heating value. Two types can be used:

• The superior heating value, also known as higher heating value or higher calorific value or

gross calorific value represents the heat released when a unit mass or volume of a mate-

rial at 1 bar pressure and 25 °C is completely combusted and the combustion products are

brought back to the starting pressure and temperature.

• The inferior heating value, also known as lower heating value or lower calorific value or net

calorific value. This quantity assumes that the water produced by combustion remains in the

vapour phase in the exhaust, and is lower than the gross calorific value by the latent heat of

condensation joules/gram) of water at 25°C multiplied by the concentration of water in the

material (expressed as grams/gram of fuel). For most common fuels, the net calorific value

is about 10% less than the gross calorific value.

3 .7 Gas normalisation

Gas is a compressible fluid, due to this fact the reference conditions (P base and T base) on

which the volume is calculated has to be given, which are normally contractually agreed.

Gas flow is measured by meters using a variety of different measurement principles, most

based on volume flow, some based on mass flow. Examples are turbine meters, orifice meters,

Coriolis meters and ultrasonic meters. In all cases the line flow is measured. The problem with

this is that two measurements in the same pipe cannot be compared, due to difference in tem-

perature, pressure and possibly the composition of the product. This also means that billing of

the gas will not be possible as no fixed tariff can be applied.

For this reason a flow computer is used to “normalize” the gas flow to standard (or base) condi-

tions, such as:

Temperature

0, 15 or 20 °C or 60 °F

Pressure

1.01325 bar or 14.73 psi