6wiring, 2 connections – Pilz PSENvip RL D P User Manual

Page 81

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: [email protected]

6-5

6.2

Connections

6

Wiring

*) Used in communication between PSENvip and safety system.

Pin assignment of M12 connector X2 on the receiver

*) Used in communication between PSENvip and safety system.

Verdrahtung_Anschluss_Empfänger_OSSD

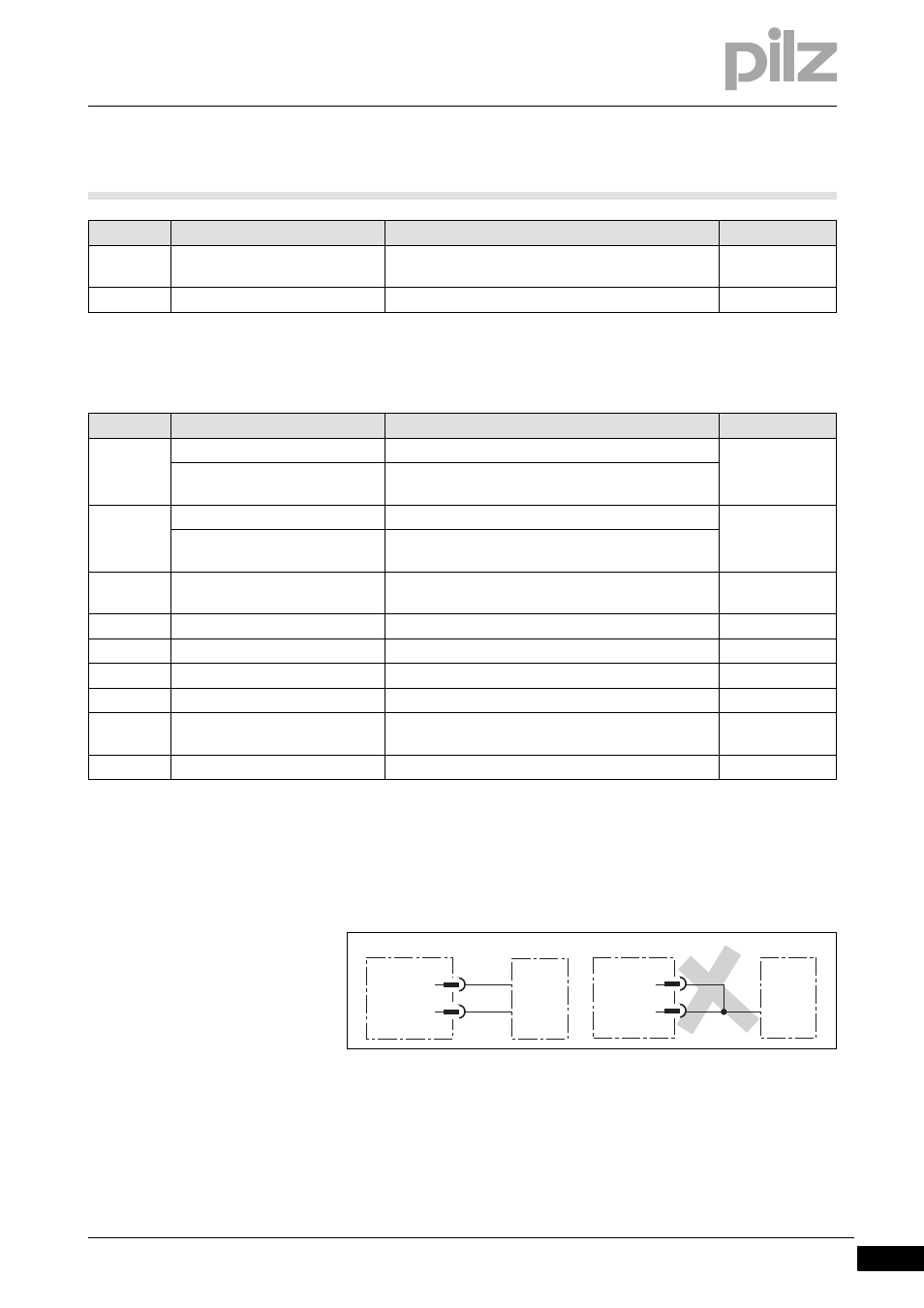

The two safety outputs OSSD1 and OSSD2 must be connected sepa-

rately to the machine's programmable safety system. OSSD1 and

OSSD2 must not be connected.

Fig. 6-4:

Correct and incorrect connection of OSSD1 and OSSD2

8

TRM_ON

Output, signal to switch the transmitter's light

source on and off

Red

Shield

Cable shield

PIn No.

Designation

Description

Colour

1

Overrun measurement 2

Output, result of overrun measurement

White

Tool class PSENvip -> PLC Bit 2

*)

Output, sends tool class Bit 2 to safety system

2

Power Off

Input, activates setup mode

Brown

PLC Ready *)

Input, safety system signals that it is ready for com-

munication

3

Acknowledgement

Input, acknowledges initiation of a press stroke with

reduced protected field

Green

4

System-Init

Input, the press is at top dead centre

Yellow

5

OSSD2

Output, OSSD2

Grey

6

Acknowledge PSENvip -> PLC *) Output, confirm validity of tool class

Pink

7

0 V

Input, 0 V supply voltage

Blue

8

TRM_SYNC

Output, signal to control the intensity of the trans-

mitter's light source

Red

Shield

Cable shield

PIn No.

Designation

Description

Colour

OSSD2

OSSD1

OSSD2

OSSD1