Bottle line example, Reference – Rockwell Automation 1761 MicroLogix 1000 Programmable Controllers User Manual

Page 371

Application Example Programs

E–21

Bottle Line Example

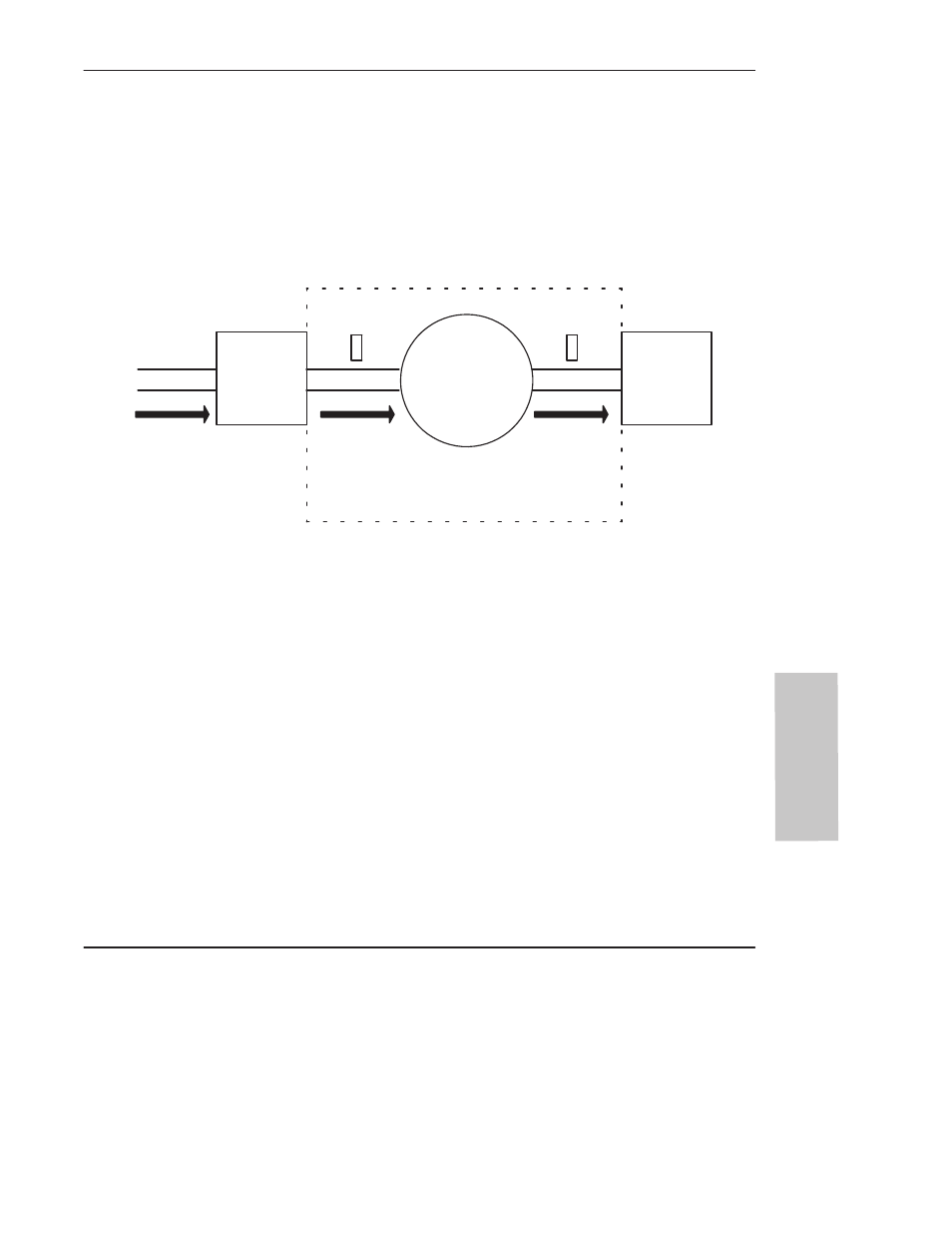

The following application example illustrates how the controller high-speed counter

is configured for an Up/down counter. For a detailed explanation of:

•

XIC, OTL, OTU and OTE instructions, see chapter 6.

•

GRT, LES, and GEQ instruction, see chapter 7.

•

HSC and HSL instructions, see chapter 12.

Stop Fill O:0/0

Slow Fill O:0/1

Sensor IN I:0/0

This section is controlled separately from the two

machines.

Sensor OUT I:0/1

Slow Pack O:0/2

Conveyor

Conveyor

Conveyor

Bottle Fill and

Cap Machine

Packing Machine

Holding Area

Bottle Line Operation Overview

The controller on the conveyor, within the specified area above, regulates the speeds

of the bottle fill and packing machines. Each machine is connected to a separate

controller that communicates with the conveyor controller. The following ladder

program is for the conveyor controller.

A conveyor feeds filled bottles past a proximity sensor (IN) to a holding area. The

proximity sensor is wired to the I/0 terminal (up count) of the conveyor controller.

The bottles are then sent on another conveyor past a proximity switch (OUT) to the

packing machine. This proximity switch is wired to the I/1 terminal (down count)

on the same controller.

Reference