Grounding guidelines – Rockwell Automation 1761 MicroLogix 1000 Programmable Controllers User Manual

Page 36

Preface

MicroLogix 1000 Programmable Controllers User Manual

2–2

Grounding Guidelines

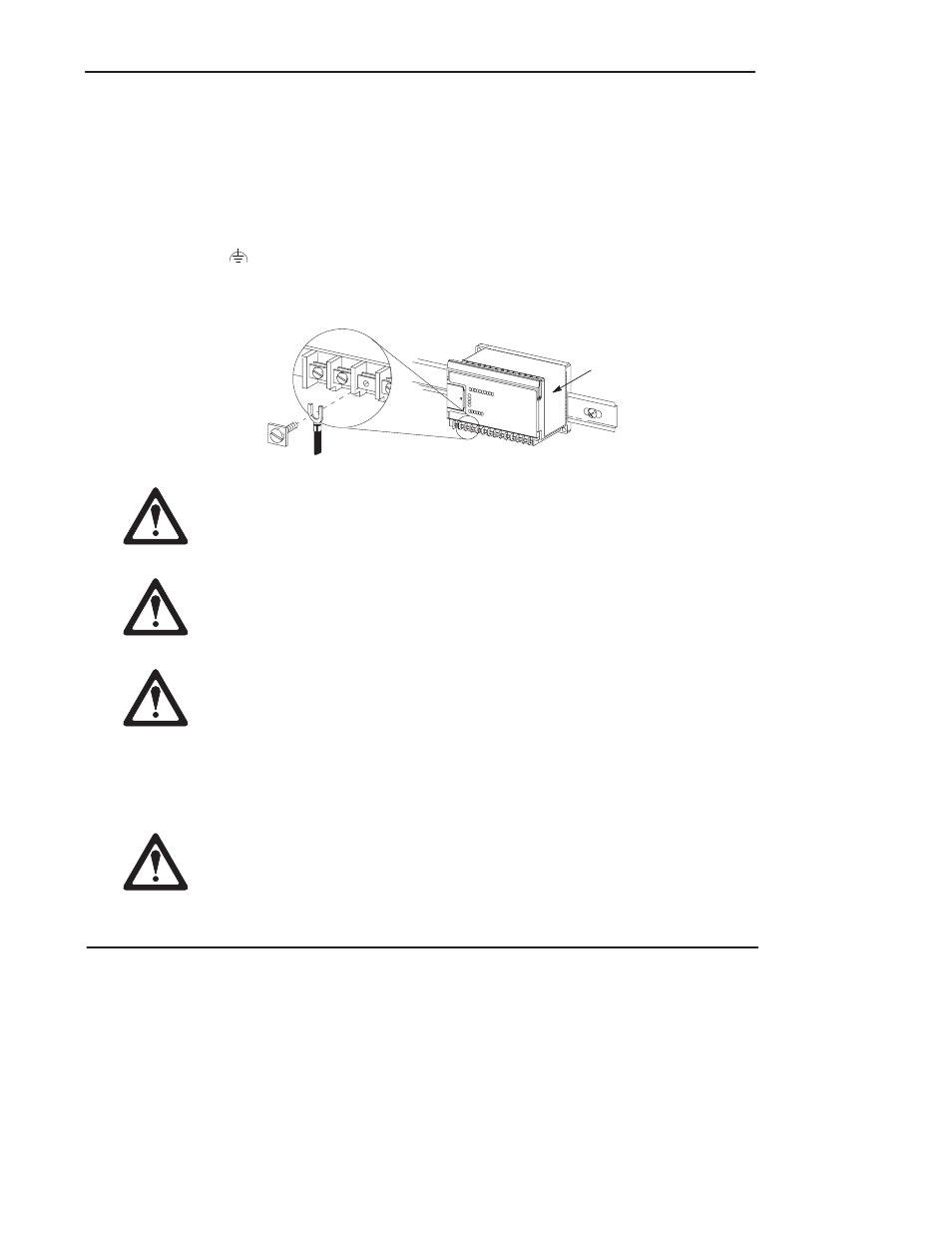

In solid-state control systems, grounding helps limit the effects of noise due to

electromagnetic interference (EMI). Use the heaviest wire gauge listed for wiring

your controller with a maximum length of 152.4 mm (6 in.). Run the ground

connection from the ground screw of the controller (third screw from left on output

terminal rung) to the ground bus.

Note

This symbol denotes a functional earth ground terminal which provides a low

impedance path between electrical circuits and earth for non-safety purposes, such

as noise immunity improvement.

Protective

Wrap (remove after wiring)

All devices that connect to the user 24V power supply or to the RS-232 channel

must be referenced to chassis ground or floating. Failure to follow this

procedure may result in property damage or personal injury.

Chassis ground, user 24V ground, and RS-232 ground are internally

connected. You must connect the chassis ground terminal screw to chassis

ground prior to connecting any devices.

On the 1761-L10BWB, 1761-L16BWB, 1761-L16BBB, 1761-L20BWB-5A,

1761-L32BBB, and 1761-L32BWB controllers, the user supply 24 V dc IN and

chassis ground are internally connected.

You must also provide an acceptable grounding path for each device in your

application. For more information on proper grounding guidelines, see the

Industrial Automation Wiring and Grounding Guidelines publication 1770-4.1.

Remove the protective wrap before applying power to the controller. Failure

to remove the wrap may cause the controller to overheat.