Technical characteristics han hv e, 04 . 02 han hv e, Technical characteristics – Northern Connectors Harting HAN Industrial Rectangular Connectors User Manual

Page 96

Han

Hv E

04

.

02

Han Hv E

®

Technical characteristics

Features

• Designed for application up to 830 V

• Available in several termination techniques

• No special tools required

• Han Hv E

®

screw requires special Han Hv E

®

housings

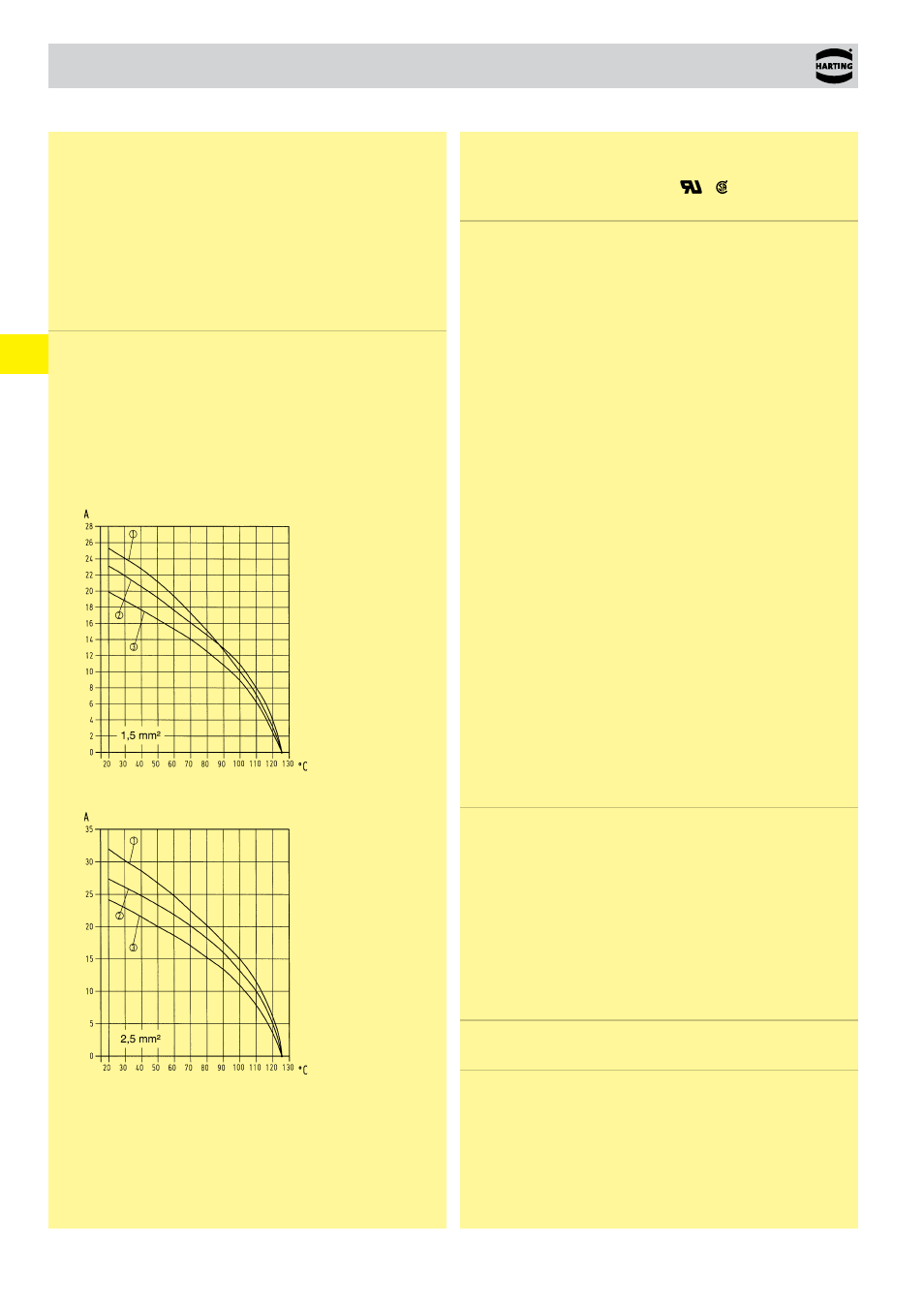

Current carrying capacity

The current carrying capacity of the connectors is limited by the

thermal load capability of the contact element material including

the connections and the insulating parts. The derating curve

is therefore valid for currents which flow constantly (non-inter-

mittent) through each contact element of the connector evenly,

without exceeding the allowed maximum temperature.

Measuring and testing techniques according to

DIN EN 60 512-5-2

Operating current

Ambient temperature

Operating current

Ambient temperature

➀ Han

®

3 Hv E

➁ Han

®

6 Hv E

➂ Han

®

10 Hv E / Han

®

16 Hv E

Specifications

DIN EN 61 984

DIN EN 60 664-1

Approvals

,

Inserts

Number of contacts

3, 6, 10, 12 (2x6), 16, 20

(2x10), 32 (2x16) + PE

+ 2 additional contacts for

safe high voltage connections

Electrical data acc. to DIN EN 61 984

Han Hv E

®

3, 6, 10, 12, 20 + PE 16 A 830 V 8 kV 3

Rated current

16 A

Rated voltage

830 V

Rated impulse voltage

8 kV

Pollution degree

3

Pollution degree 2 also

16 A 1000 V 8 kV 2

or

16 A 720/1250 V 8 kV 2

Relay contacts

16 A 500 V 6 kV 3

Han Hv E

®

16, 32 + PE

16 A 400/690 V 6 kV 3

Rated current

16 A

Rated voltage conductor - ground

400 V

Rated voltage conductor - conductor 690 V

Rated impulse voltage

6 kV

Pollution degree

3

or

16 A 500 V 6 kV 3

Rated voltage

acc. to UL/CSA

600 V

Relay contacts

250 V

Insulation resistance

≥ 10

10

Ω

Material polycarbonate

Limiting temperatures

-40 °C ... +125 °C

Flammability acc. to UL 94

V 0

Mechanical working life

- mating cycles

≥ 500

Contacts

Material

copper alloy

Surface

- hard-silver plated

3 µm Ag

Contact resistance

≤ 1 mΩ

Crimp terminal

- Wire gauge

1)

0.5 ... 4 mm²

- AWG

20 ... 12

Screw terminal

- Wire gauge

1)

2.5 mm²

- AWG

14

- Tightening/test torque

0.5 Nm

Hoods/Housings

Technical characteristics

see page 04.03

Accessories

Crimping tools

chapter 99

Cable clamps

chapter 95

Coding of hoods/housings

chapter 95

Label acc. to CSA-approval

chapter 95

Han-Snap

®

chapter 11

1)

geometric wire gauge