Spreader control screen, Conveyor rate look-up, Pplication – Kinze Ag Leader Integra User Manual

Page 299: Preader

283

A

PPLICATION

S

PREADER

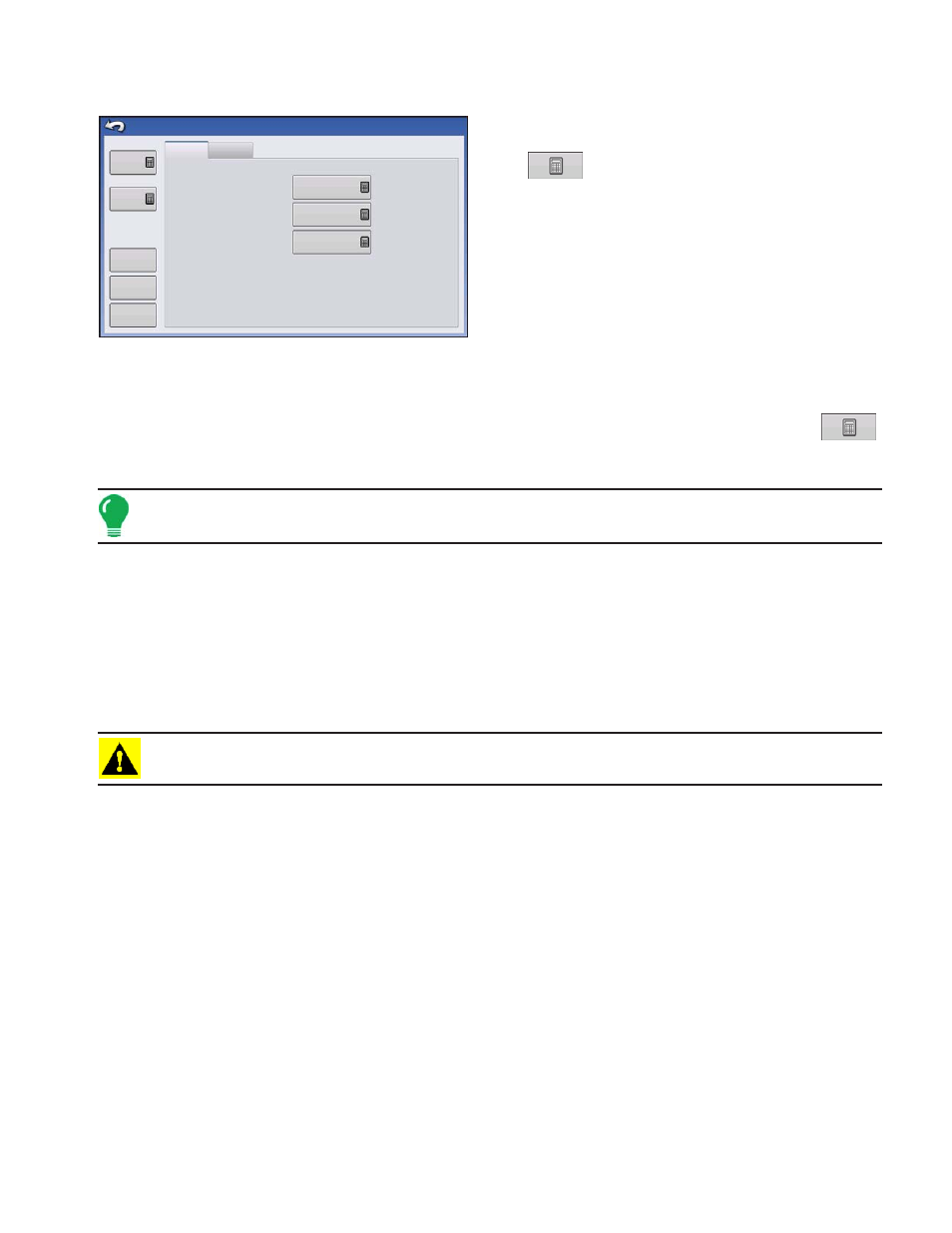

Spreader Control screen

• Spread Width

Press

to edit the value.

• Spinner Speed

The spinner speed required for accurate product

placement in relation to the spread width setting.

- The spinner speed is controlled automatically based upon

this setting when the system uses an optional PWM

spinner speed control valve.

- To accurately determine Spinner Speed settings you

should perform a spread pattern catch test. See

Control: Static Calibration” on page

.

• Product Density

This density value (shown in pounds per cubic foot, or lb./ft.3), is stored with each product. Press

to edit if needed.

Note: For proper machine performance and accuracy, you should check the Product Density daily.

• Feed Gate 1 Opening

Represents the Feed Gate opening for Conveyor 1. Measure the depth of product on the conveyor to

ensure accurate feed gate setting value.

• Conveyor 1 Rate

This setting represents the volume of product dispensed by one revolution of the conveyor drive shaft (cubic

foot per revolution, or ft

3

/rev.) This number is shown with the assumption that the conveyor shaft has a 1-

inch gate opening. This conveyor rate remains constant, regardless of the height of the feed gate opening.

CAUTION: You must either manually enter conveyor rate value or perform a CFR calibration routine for each

product and channel combination, otherwise misapplication will occur.

Conveyor Rate Look-Up

A pop-up screen will display a warning when a product is assigned to a container or bin for the first time

and has not been calibrated. The warning prompts the operator to review product density and conveyor

rate settings.

Spreader Control

Channel 1

Channel 2

Spread Width

60 ft

Spinner Speed

600 rpm

58 lb/ft

3

2 in

0.256 ft

3

/rev

Product

Conveyor 1

Feed Gate 1

In-Field

Static

Chain

DAP