Analog speed pin outs, Direct injection: application error, Direct injection: discharge flow sensor error – Kinze Ag Leader Integra User Manual

Page 272: Nalog, Peed

256

Firmware Version 5.2

A

NALOG

S

PEED

P

IN

O

UTS

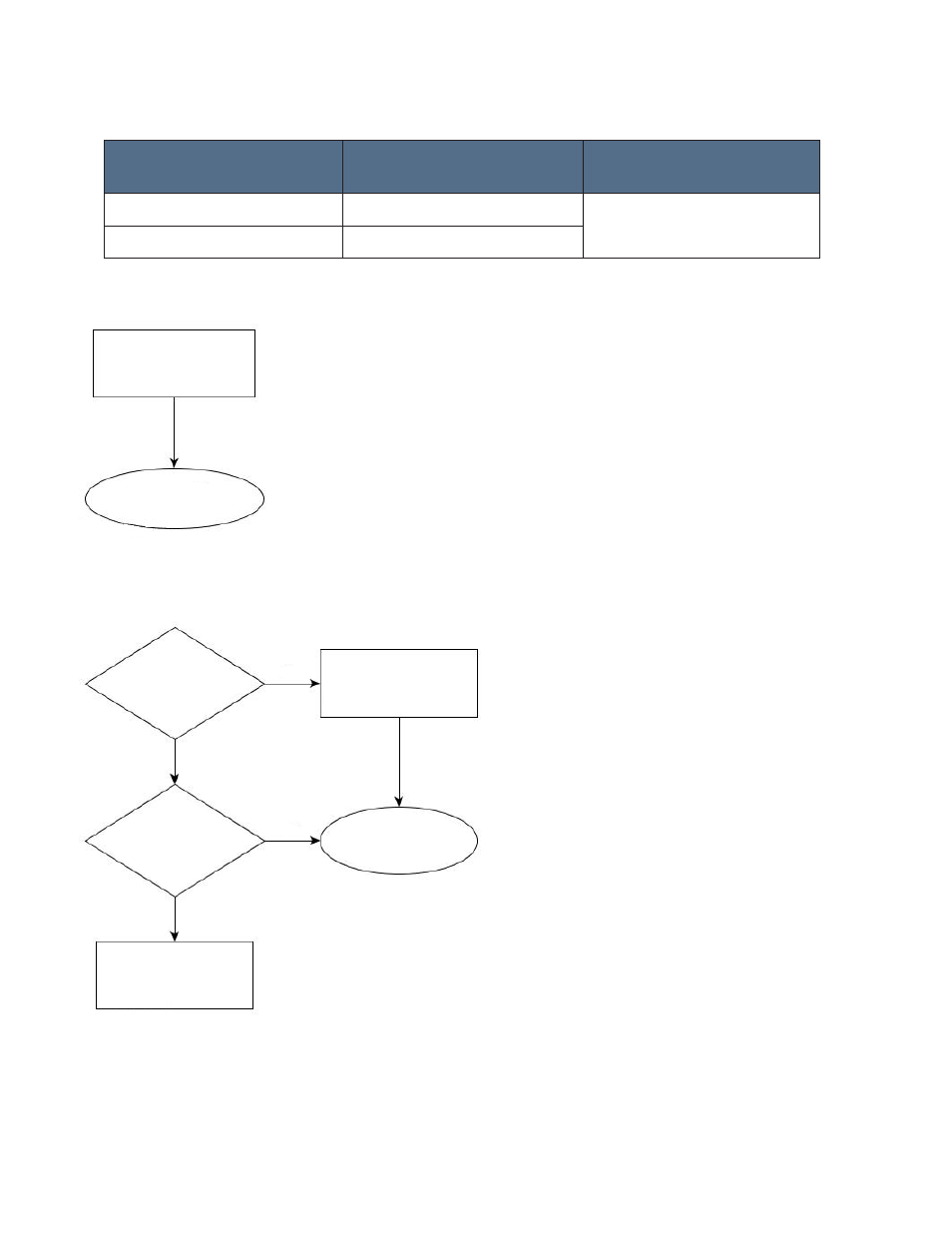

Direct Injection: Application Error

The injection module requires that a pump calibration be performed before

actual application can occur. The calibration number found on the tag of the

injection pump’s digital speed sensor needs to be divided by a factor of 10

before entering it as the factory calibration number. If the factory cal

number is entered wrong, the pump calibration routine will not finish due to

a high application error.

Notes:

• The pump calibration will fail if error is >10% from the factory calibration

number.

• If the calibration fails check pump and plumbing for physical damage or excess

wear.

Direct Injection: Discharge Flow Sensor Error

The discharge flow sensor is used as a system

check to see if product is actually exiting the

output of the pump. The sensor is a shuttle

valve that allows feedback for every stroke of

the pump. If Flow Monitor Warning is enabled,

the display will provide a message if the

discharge flow sensor falls out of its calibrated

value. See table below for pin locations.

Module Auxiliary Connection

12-Pin Socket

3-Pin Conxall

Signal

A

>9V at max pump speed

Ground

B

Verify factory calibration

number is pump cal/10

Refer to injection

calibration routine

No

Yes

No

Yes

Status light on run

screen showing green

LED light on the

injection pump flashing

Check error threshold

found in the controller

Check injection

diagnostics to see if

Refer to manufacturer

documentation to test