Positioning the media sensors – Printronix SL5000r RFID Smart Label and Thermal Printers User Manual

Page 66

66

Chapter

2

Printing Adjustments

3.

Press the

↵ key to start the Grey test pattern. The pattern will start and

continue to print.

4.

Press

↵ again to stop printing.

5.

Check the test pattern. If necessary reposition the pressure blocks to

obtain a uniform print density across the media width. In most cases, only

the right pressure block may need to be adjusted.

6.

Whenever you reposition a pressure block, run the Grey test pattern to

verify the print pattern is acceptable.

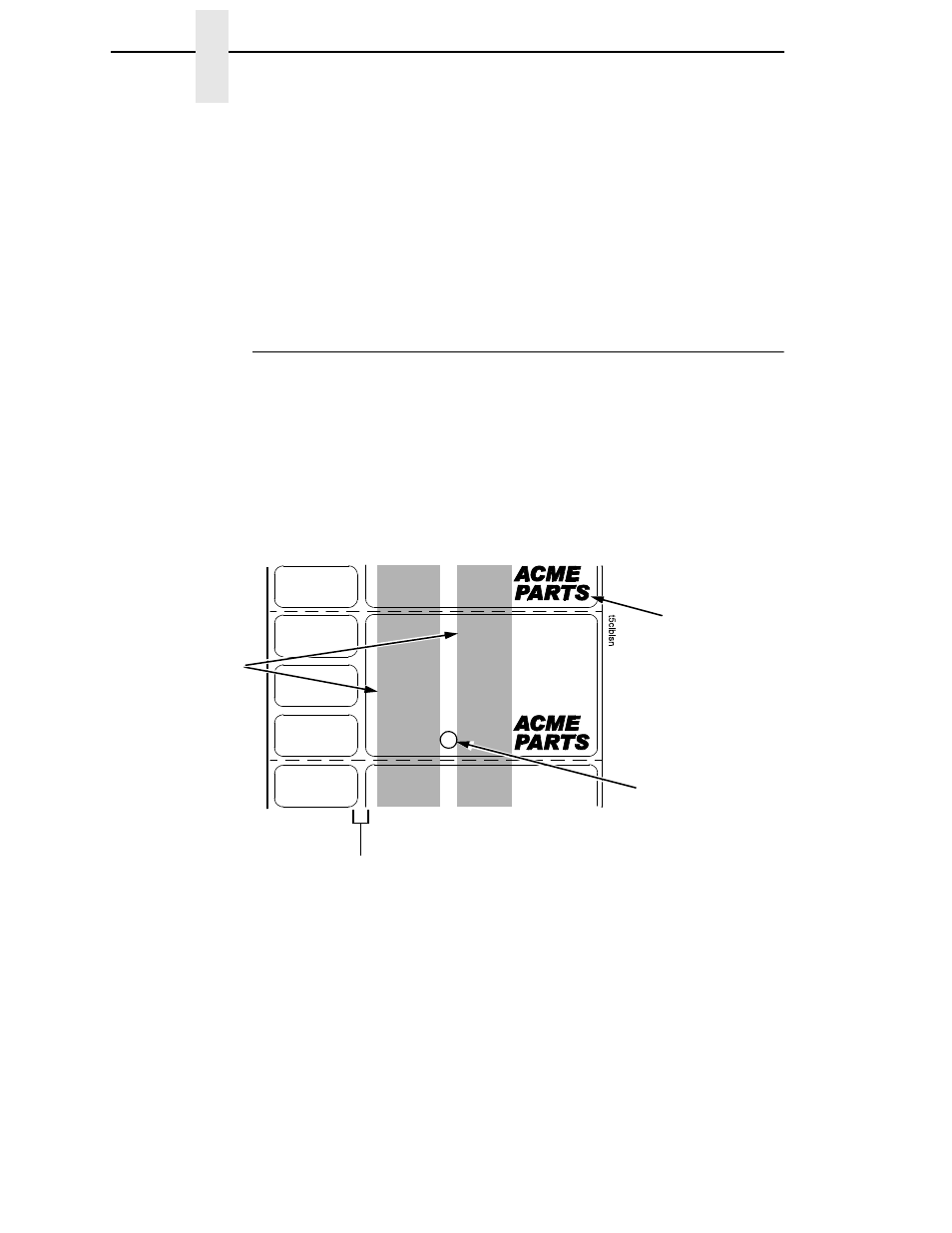

Positioning The Media Sensors

Your printer is equipped with upper and lower media sensors that detect the

top-of-form position on media with label length indicators (gaps, notches,

holes, or black marks). These sensors also detect when a Paper Out

condition exists.

The media sensors should not be placed in the path of media features that

could cause false gap detection or paper out faults. Such features are dark

pre-printing, rounded die-cut label corners, vertical gaps associated with

side-by-side labels, and extraneous cut-outs, as shown below.

Vertical Gap and

Rounded Die-cut

Label Corners

Extraneous Cut-out

Dark Pre-printing

Position the media

sensors in either of

the grey shaded

areas.