Printronix SL5000r RFID Smart Label and Thermal Printers User Manual

Page 312

312

Chapter

6

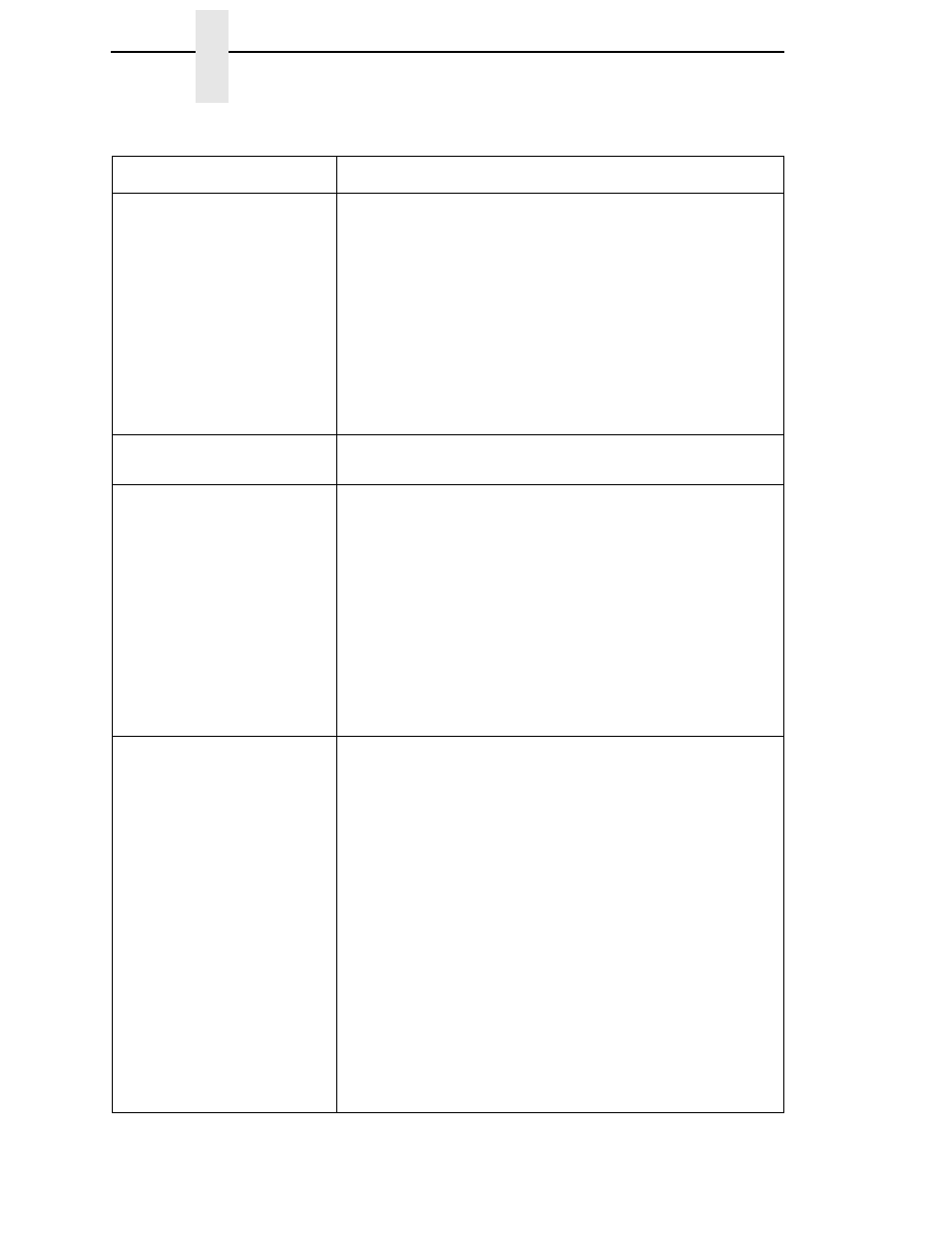

Restore The Printer To Operation

Printing is faded or of poor

quality.

1.

Clean the printhead.

2.

Check that both latches on the pivoting deck are closed

and latched. Close the printhead by pressing down on

both sides of the pivoting deck and rotating the deck lock

lever fully counterclockwise.

3.

Verify that the head pressure adjustment dial is properly

set. Try increasing the pressure.

4.

Verify that the Print Speed and Print Intensity values are

correct. Adjust Print Speed and Print Intensity in the

QUICK SETUP menu, MEDIA CONTROL menu, or via

host software.

Print is light on the left or right

side of the label.

Check if the pressure blocks are set for the width of the media

being used. Set each block near the edge of the media.

Prints strange characters

instead of the correct label

format.

1.

If the printer serial interface is being used, check that the

printer serial baud rate setting matches the baud rate of

the host computer. Reset the printer via software, or turn

the printer off and then on.

2.

Check if the printer serial host interface is set for 8 data

bits but the transmitting device is set for 7 data bits (or

vice-versa). Check the current setting by viewing it on the

LCD, and use the SERIAL PORT menu to adjust the

settings, if necessary.

3.

If the printer parallel interface is being used, make sure the

parallel interface terminating resistors are correct for the

host computer drivers.

•

Start of image is printed

an erroneous distance

from the top-of-form.

•

The printer starts to print

one label and then

another, all within the

same physical label.

1.

Make sure the Label Length value matches the actual

physical length of the label installed and the run on Auto

Calibrate (see page 72).

These symptoms could be caused by:

•

severely curled labels near the end of a media roll

•

the media sensor triggering off of a dark, preprinted image

on the label

•

multiple gaps within the physical label.

2.

In the MEDIA CONTROL menu, set Clip Page to Disable.

3.

Run a Media Profile (see page 74).

4.

If the Media Profile printout shows that preprinted images

or an RFID antenna tag has an amplitude approaching the

Gap/Mark Threshold level, position the lower media

sensor to avoid the image or increase the Threshold

Range percent value in the Calibrate CTRL menu. Run

Auto Calibrate again and Media Profile to verify there is an

improvement.

Table 16. Printer Problems and Solutions (continued)

Symptom

Solution/Explanation