As shown in – Rockwell Automation 1336T FORCE Series B User Manual

Page 116

Chapter 4

Startup

4–25

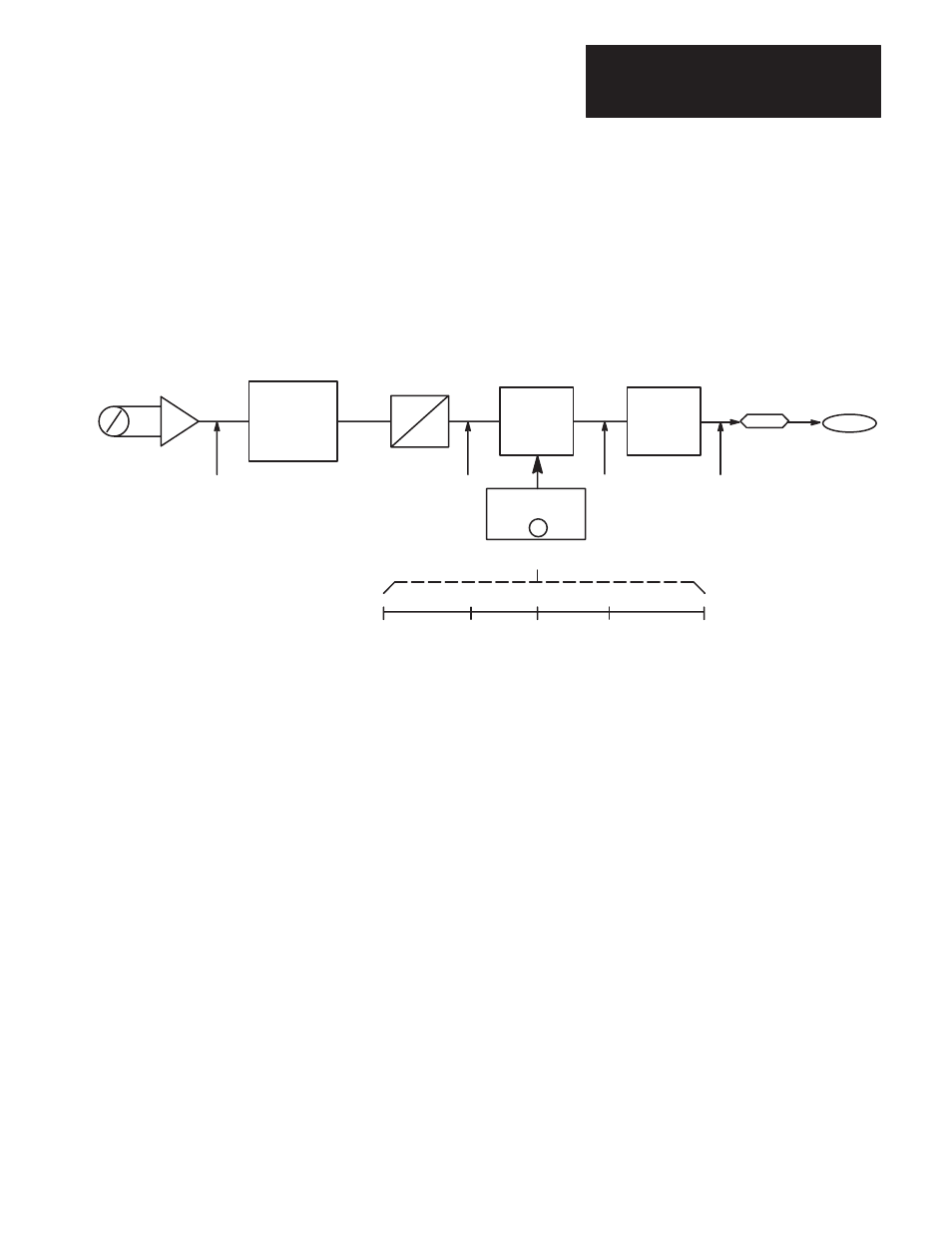

As shown in

Figure 4.9

, the offset voltage adds the corresponding digital

value to the range. In this case, an offset of –5 volts adds a digital value of

–1024 to the range. This causes 0 volts on the potentiometer to register as

–1024 digital internal to the drive and 10 volts on the potentiometer will be

+1024 to the drive. This can then be scaled by a factor of 4

(8192 drive units) so that 0 volts sends a digital value of –4096 for –100%

torque, and 10 volts sends a digital value of +4096 for +100% torque.

Figure 4.9.

Potentiometer 0–10V Range to Control +/– 100% Torque Reference

0–10V POT

0

10v

A

D

SCALE

0

to

2048

–1024

+1024

+4096

+4096

RANGE OF 20V

0

0

0

–10V

–2048

+10V

+2048

PAR 357

X 4

+0v

POTENTIOMETER

DIGITAL VALUE

OFFSET BY –5V

10V

–10V

5V

1024

0

0

–1024

–4096

+1024

+4096

ADDING –1024

SCALE BY 4

PAR 162

±

2048

(=

±

10V)

OFFSET

Par 356 = –5V

Par 355

MULTIPLEXER

10V Input

Analog outputs are set up similar to analog inputs. Each output has a scale

and offset parameter, along with a specific variable parameter used for

linking. Differences occur because of the direction of information flow. The

drive sends a digital value in drive units, which must be matched to the

voltage of the monitoring device. Similar to analog inputs, the analog output

converts a

±

2048 to

±

10VDC. Thus, when the drive sends

±

100% Base

Speed (equal to

±

4096) it must be scaled by 0.5 to be in the proper range

(

±

4096

×

0.5 =

±

2048). Offset can be

±

20VDC, even though the physical

limit is

±

10VDC. This allows you to offset the signal anywhere within the

entire range.