4096 to, Dc as shown in figure 4.8 – Rockwell Automation 1336T FORCE Series B User Manual

Page 115

Chapter 4

Startup

4–24

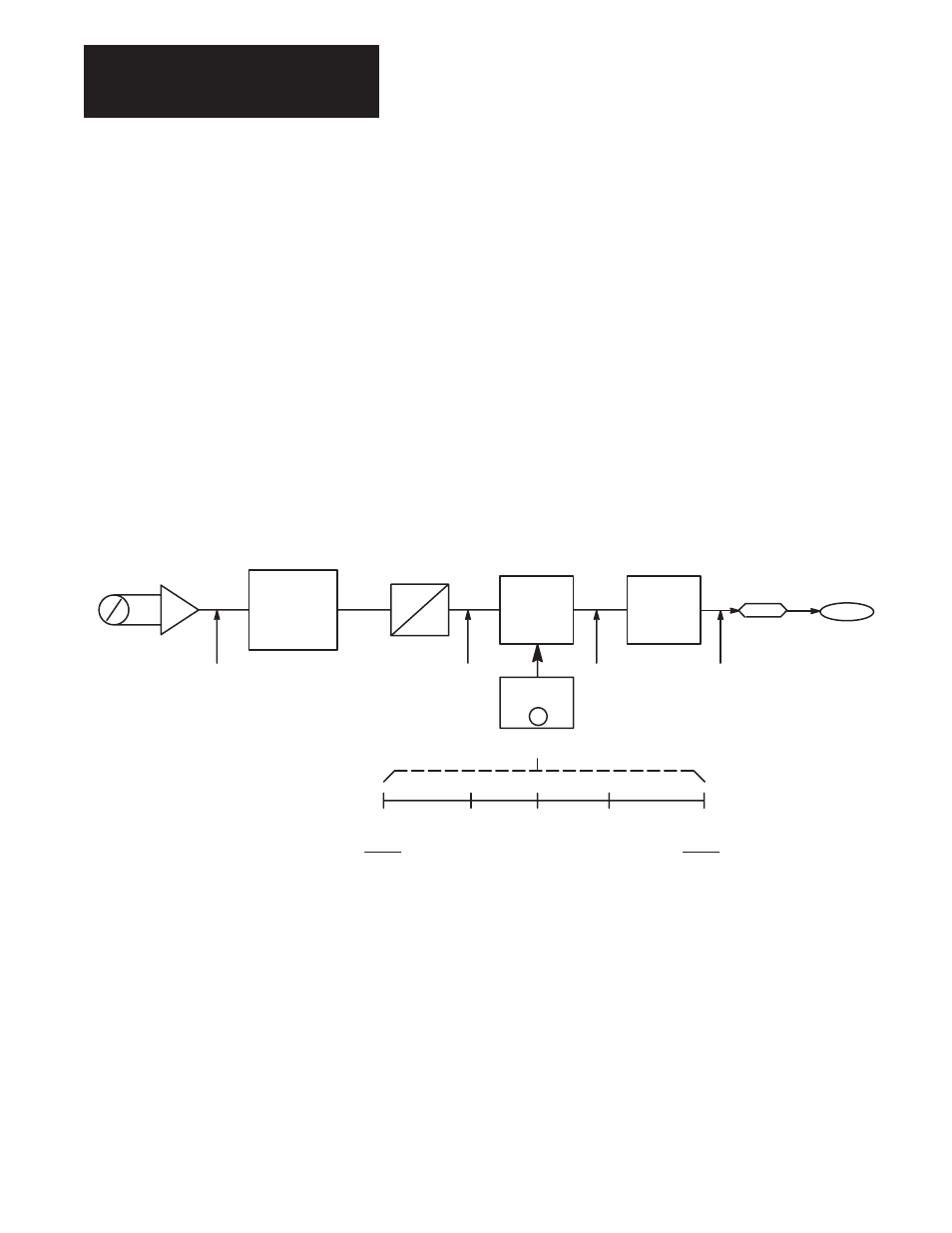

A 10V Input and a Pot Input will be used in detailing the scaling and offset

parameters. At Pot Input, between TB5 terminals 7 and 8, a potentiometer

with a range of

±

10V

DC has been connected. Parameter 358 has been linked

to Parameter 104 (Velocity Reference 2 HI) in the Drive, which gives the

potentiometer control of the external velocity reference. To calibrate the pot

to control 100% base speed in both directions, the scaling parameter must be

adjusted. The default value of the scale parameters allows a total range of

4096, –2048 to +2048. This allows only 50% base speed in each direction.

By setting a scale factor of 2 in Parameter 360 (An In 1 Scale) the digital

input is multiplied by 2, providing a range of –

4096 to +

4096, or 100% base

speed in both directions. If the user wanted a range of

±

2 times base speed,

the scale factor would have to be 4 (Base Speed = 4096, 2 times Base Speed

= 8192, 2048 times 4 = 8192). Parameter 359 (Offset) will remain at the

default value of zero, allowing the input range to be –10V to +10V. The

range of the offset parameter is

±

20V

DC as shown in Figure 4.8.

Figure 4.8.

Potentiometer with a +10V Range to Control 0 to +100% Base Speed

10V POT

0

–10V

A

D

SCALE

+2048

0

–2048

+2048

0

–2048

+4096

0

–4096

OFFSET

PAR 359 = 0

RANGE OF 20V

0

0

0

0

–10V

–2048

X 2

–4096

+10V

+2048

X 2

+4096

PAR 360

X 2

±

+10V

POTENTIOMETER

DIGITAL VALUE

SCALE

FINAL VALUE PAR 401

PAR 104

±

2048

(=

±

10V)

Par 358

Pot Input

VELOCITY

REFERENCE 2

HI

MULTIPLEXER

For 10V Input, a 0 to 10 volt potentiometer will be used to adjust the Torque

Reference from –100% to +100%. To accomplish this, both the scale and

offset parameters will need to be adjusted. By linking Parameter 355 to

Parameter 162, Torque Reference, the potentiometer connected to Analog

Input becomes the Torque Reference Signal. This signal must be scaled and

offset in order to get the entire

±

100% in the 0-10 volt range. A digital

range of 8192 (

±

4096) must now be scaled for an analog range of 10 volts,

and must be offset so 5 volts on the potentiometer will indicate 0% Torque.