Drive 4 control routine – Rockwell Automation 25-COMM-D PowerFlex 525 DeviceNet Adapter User Manual

Page 81

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013

81

Using Multi-Drive Mode

Chapter 7

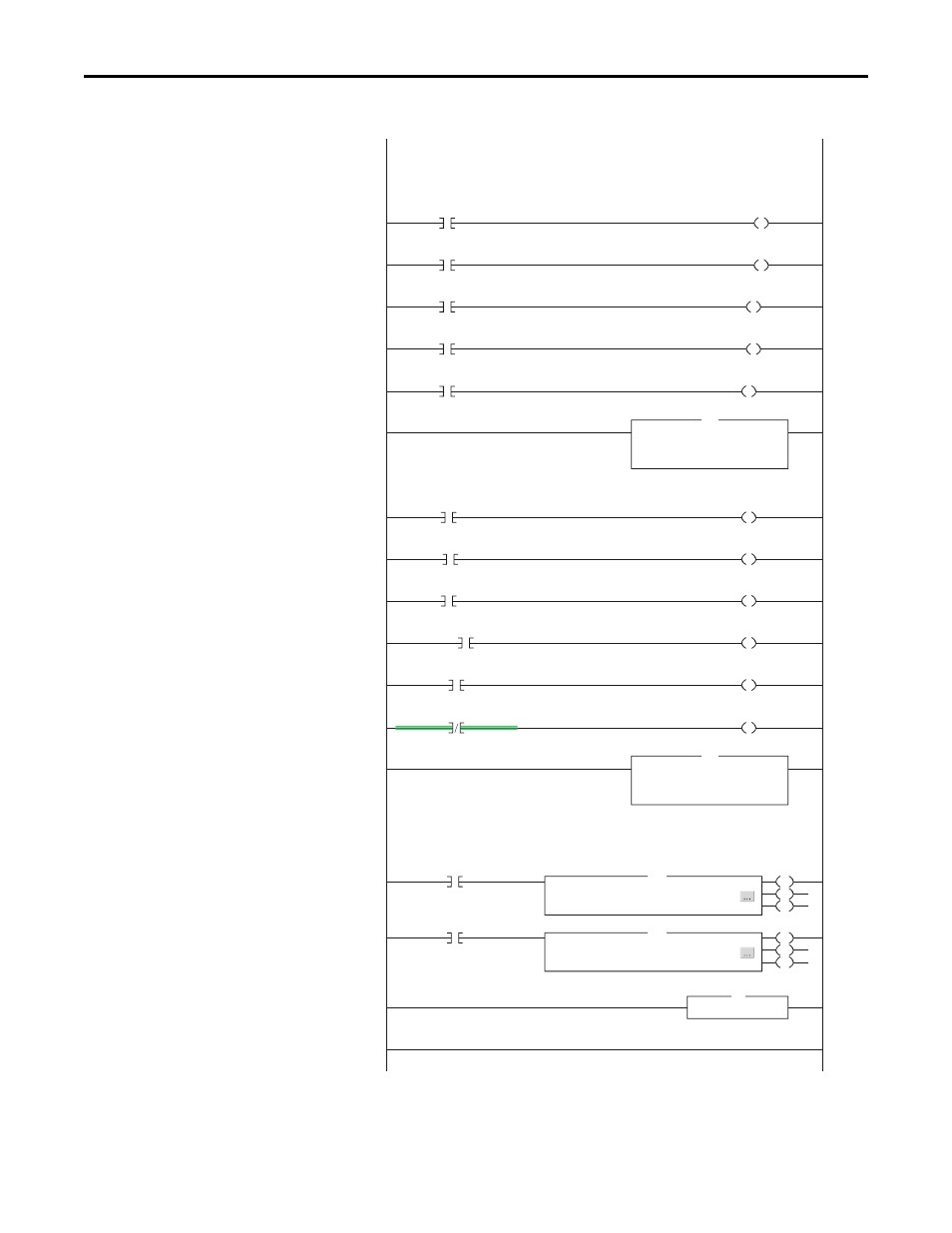

Drive 4 Control Routine

0

5

(End)

Copy File

Source

Dest

Length

Drive_Input_Image[9]

Drive_4_Feedback

1

COP

12

Copy File

Source

Dest

Length

Drive_4_Reference

Drive_Output_Image[9]

1

COP

15

Return from Subroutine

RET

Drive_Input_Image[8].0

Drive_4_Status_Ready

This section takes the data from the input area and moves it to specific tags (Logic Status bits and Feedback) for use

elsewhere in the ladder program.

This section takes the data from specific tags (Logic Command bits and Reference) and moves them to the output

image area for transmission to the scanner.

Drive 4 parameters are accessed by adding 21504 decimal (5400 hex) to the desired parameter number.

For example, to access parameter P109 an Instance of 21613 (21504 + 109) is used.

1

Drive_Input_Image[8].1

Drive_4_Status_Active

2

Drive_Input_Image[8].3

Drive_4_Status_Forward

3

Drive_Input_Image[8].7

Drive_4_Status_Faulted

4

Drive_Input_Image[8].8

Drive_4_Status_At_Reference

6

Drive_4_Command_Stop

Drive_Output_Image[8].0

7

Drive_4_Command_Start

Drive_Output_Image[8].1

8

Drive_4_Command_Jog

Drive_Output_Image[8].2

9

Drive_4_Command_Clear_Faults

Drive_Output_Image[8].3

10

Drive_4_Command_Forward

Drive_Output_Image[8].4

13

Perform_Parameter_Read_4

EN

DN

ER

11

Drive_4_Command_Forward

Drive_Output_Image[8].5

Type – CIP Generic

Message Control Parameter_RD_Message_4

MSG

14

Perform_Parameter_Write_4

EN

DN

ER

Type – CIP Generic

Message Control Parameter_WR_Message_4

MSG

Explicit Messaging Example

Drive 4 Control Subroutine