General maintenance – SkyTrak 3606 Operation Manual User Manual

Page 151

General Maintenance

3606 Rev 11/99

149

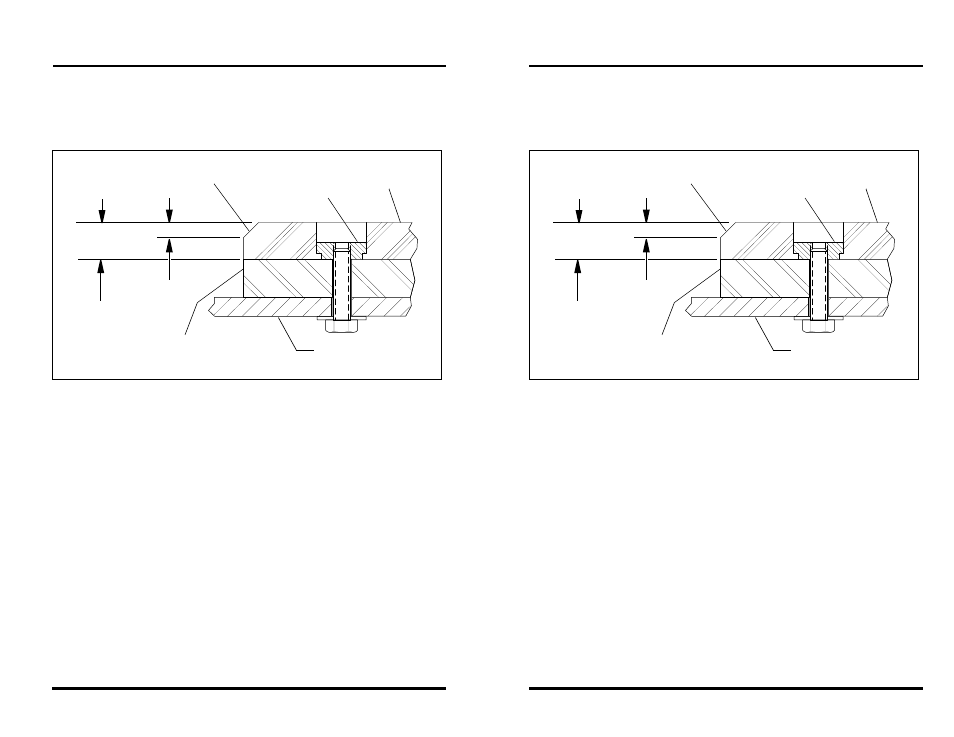

D. Wear Pad Replacement

(As Wear Pad Indicators Indicate)

Each boom wear pad is manufactured with a convenient wear pad indicator.

This is the angled cut at each end of all wear pads (Figure 104).

Figure 104

The total thickness of a new wear pad is .625” (15,9 mm). The angled cut

will provide a total wear thickness of .25” (6,4 mm). This will leave

approximately .375” (9,5 mm) of total unused base material.

The pads must never be worn past the angled cut indicator because the

metal pad insert that holds the pads in place will begin to wear into the

boom pad sliding surfaces. If the pads are worn past this point it will cause

gouging on the boom plate surfaces. This will result in premature wear of

any new wear pads installed if the surfaces are not ground smooth again.

Replacement of boom wear pads must performed by an authorized Sky

Trak distributor when the wear pads indicate.

IMPORTANT! The boom has been factory lubricated for proper wear pad

break-in and will normally not require further lubrication. However, after

replacing any wear pad(s), or after prolonged periods of inoperation, light

lubrication (“LPS-3” or “LUBRIPLATE” chain and cable fluid or equivalent) of

the boom wear surfaces is recommended to keep the wear pads and the

boom wear surfaces lubricated properly. Light lubricating of the boom wear

surfaces is also recommended in salt air climates or when the vehicle is to

be put in storage to prevent rusting.

OS1230

Angular Cut

(Wear Pad Indicator)

.625”

(15,9 mm)

.25”

(6,4 mm)

Boom

Plate

Wear

Pad Spacer

Metal

Insert

Wear

Pad

General Maintenance

3606 Rev 11/99

149

D. Wear Pad Replacement

(As Wear Pad Indicators Indicate)

Each boom wear pad is manufactured with a convenient wear pad indicator.

This is the angled cut at each end of all wear pads (Figure 104).

Figure 104

The total thickness of a new wear pad is .625” (15,9 mm). The angled cut

will provide a total wear thickness of .25” (6,4 mm). This will leave

approximately .375” (9,5 mm) of total unused base material.

The pads must never be worn past the angled cut indicator because the

metal pad insert that holds the pads in place will begin to wear into the

boom pad sliding surfaces. If the pads are worn past this point it will cause

gouging on the boom plate surfaces. This will result in premature wear of

any new wear pads installed if the surfaces are not ground smooth again.

Replacement of boom wear pads must performed by an authorized Sky

Trak distributor when the wear pads indicate.

IMPORTANT! The boom has been factory lubricated for proper wear pad

break-in and will normally not require further lubrication. However, after

replacing any wear pad(s), or after prolonged periods of inoperation, light

lubrication (“LPS-3” or “LUBRIPLATE” chain and cable fluid or equivalent) of

the boom wear surfaces is recommended to keep the wear pads and the

boom wear surfaces lubricated properly. Light lubricating of the boom wear

surfaces is also recommended in salt air climates or when the vehicle is to

be put in storage to prevent rusting.

OS1230

Angular Cut

(Wear Pad Indicator)

.625”

(15,9 mm)

.25”

(6,4 mm)

Boom

Plate

Wear

Pad Spacer

Metal

Insert

Wear

Pad