General maintenance, Engine fan belt – SkyTrak 3606 Operation Manual User Manual

Page 128

126

3606 Rev 11/99

General Maintenance

A. Engine Fan Belt Check

(1000 Hour Intervals)

1. Ground the carriage, place the travel select lever in (N) NEUTRAL,

engage the parking brake switch and shut off the engine.

2. Unlatch, unlock and open the engine cover.

3. Inspect the fan belt. Replace if cracked or frayed.

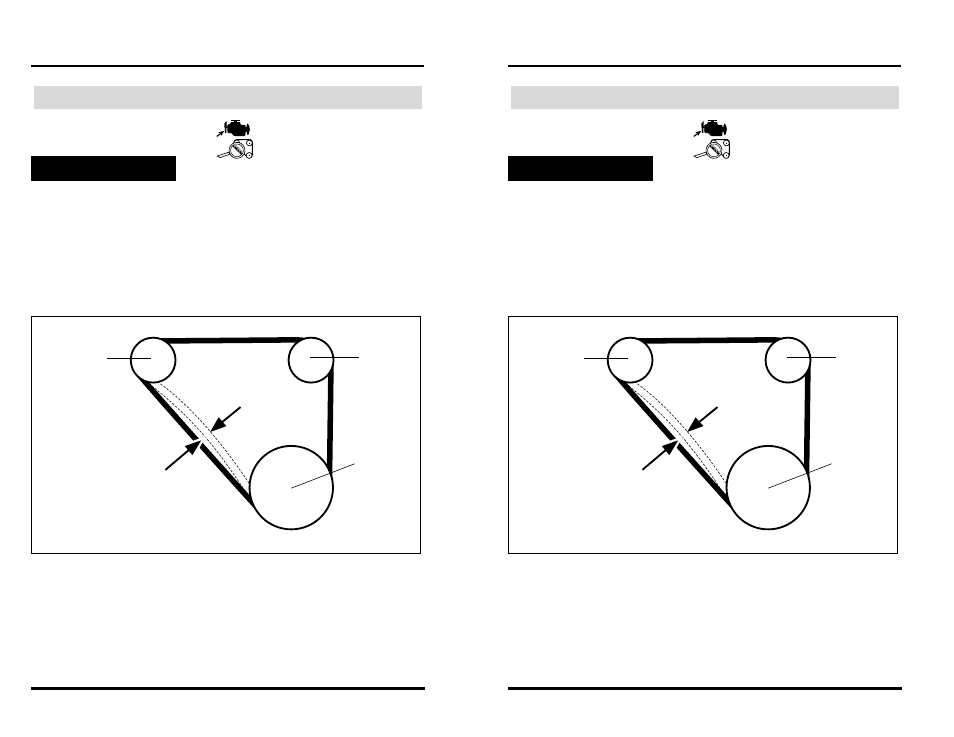

4. Check the belt tension midway between the crankshaft and alterna-

tor pulleys (Figure 82). Deflection should be 1/4 to 3/8 inch (6,4 to

9,4 mm) with an applied force of 13 to 15 lbs (6 to 7 Kg).

Figure 82

5. If the belt needs adjustment, loosen both alternator mounting bolts

and carefully pry the alternator to tighten the belt. DO NOT over-

tighten. Retighten mounting bolts.

6. Recheck the belt deflection.

7. Close, latch and lock the engine cover.

7. Engine Fan Belt

PERKINS ENGINE:

OS0880

OA0362

1/4 to 3/8 inch

Deflection

(6,4 to 9,4 mm)

Fan

Pulley

Crankshaft

Pulley

Alternator

Pulley

126

3606 Rev 11/99

General Maintenance

A. Engine Fan Belt Check

(1000 Hour Intervals)

1. Ground the carriage, place the travel select lever in (N) NEUTRAL,

engage the parking brake switch and shut off the engine.

2. Unlatch, unlock and open the engine cover.

3. Inspect the fan belt. Replace if cracked or frayed.

4. Check the belt tension midway between the crankshaft and alterna-

tor pulleys (Figure 82). Deflection should be 1/4 to 3/8 inch (6,4 to

9,4 mm) with an applied force of 13 to 15 lbs (6 to 7 Kg).

Figure 82

5. If the belt needs adjustment, loosen both alternator mounting bolts

and carefully pry the alternator to tighten the belt. DO NOT over-

tighten. Retighten mounting bolts.

6. Recheck the belt deflection.

7. Close, latch and lock the engine cover.

7. Engine Fan Belt

PERKINS ENGINE:

OS0880

OA0362

1/4 to 3/8 inch

Deflection

(6,4 to 9,4 mm)

Fan

Pulley

Crankshaft

Pulley

Alternator

Pulley