Cascade – Watlow Series F4S/D User Manual

Page 75

Wa t l o w S e r i e s F 4 S / D

F e a t u r e s

■

6 . 1 1

Cascade

Cascade control is a control strategy in which one

control loop provides the set point for another loop.

It allows the process or part temperature to be

reached quickly while minimizing overshoot. Cas-

cade is used to optimize the performance of thermal

systems with long lag times.

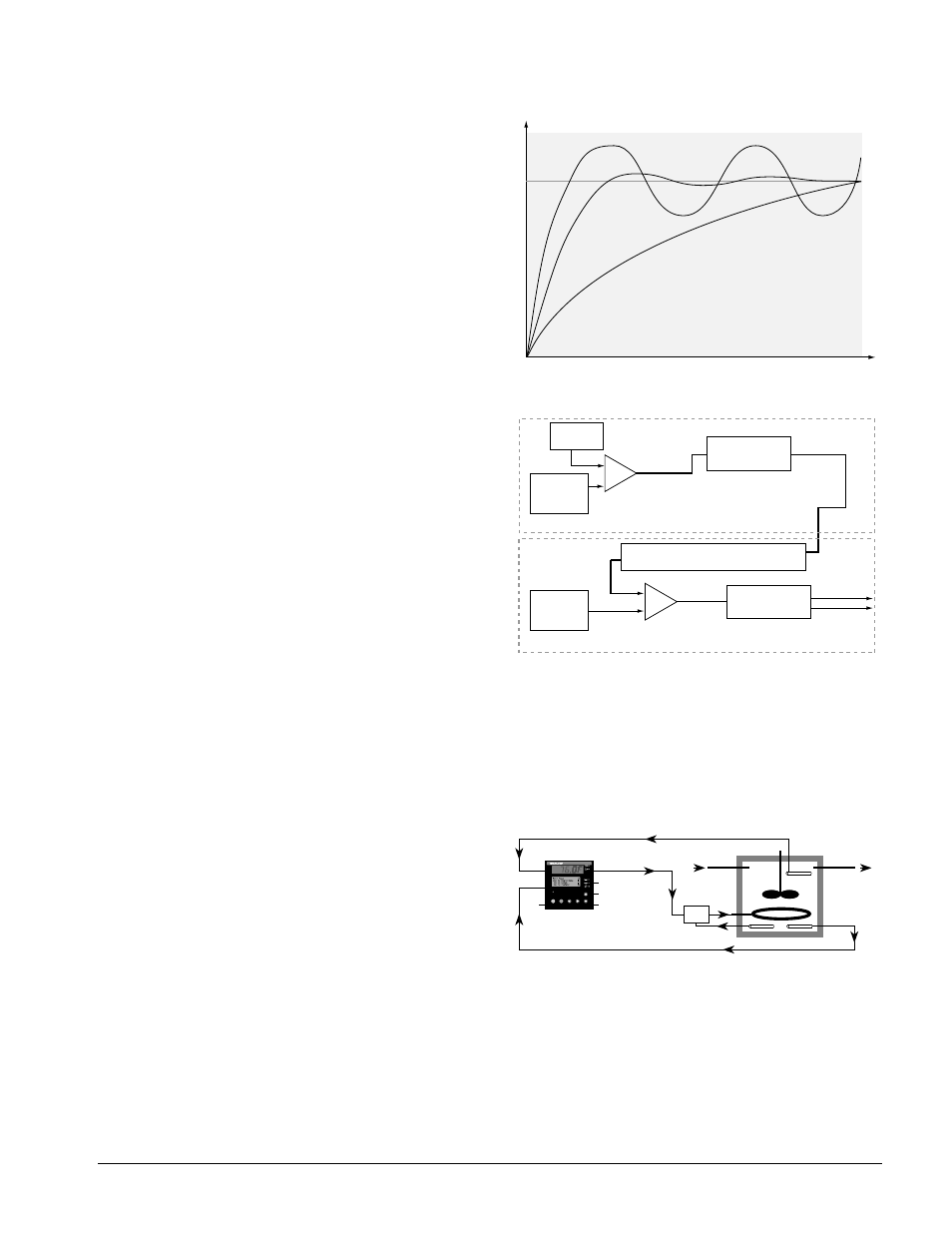

This graph illustrates a thermal system with a long

lag time. Curve A represents a single-loop control

system with PID parameters that allow a maximum

heat-up rate. Too much energy is introduced and the

set point is overshot. In most systems with long lag

time, the process value may never settle out to an

acceptable error. Curve C represents a single-control

system tuned to minimize overshoot. This results in

unacceptable heat-up rates, taking hours to reach

the final value. Curve B shows a cascade system

that limits the energy introduced into the system,

allowing an optimal heat-up rate with minimal over-

shoot.

Cascade control uses two control loops (outer and in-

ner) to control the process. The outer loop (analog

input 3) monitors the process or part temperature,

which is then compared to the set point. The result

of the comparison, the error signal, is acted on by

the settings in a Cascade Outer Loop PID set (1 to

5), which then generates a power level for the outer

loop. The set point for the inner loop is determined

by the outer-loop power level and the Cascade Low

Range/Deviation and the Cascade High Range/Devi-

ation settings for analog input 3.

The inner loop (analog input 1) monitors the energy

source (heating and cooling), which is compared to

the inner loop set point generated by the outer loop.

The result of the comparison, the error signal, is act-

ed on by the settings in a Cascade Inner Loop PID

set (1 to 5), which generates an output power level

between -100% to +100%. If the power level is posi-

tive the heat will be on; if the power level is nega-

tive the cool will come on.

In Series F4 controllers, cascade control is available

on channel 1. Analog input 3 is used to measure the

outer-loop process while analog input 1, the inner

loop, is used to measure the energy source. Power

from the energy sources are supplied by outputs 1A

and 1B.

To set up and tune a system for cascade control, see

the Operations Chapter.

Location in software: Setup Page and Operations

Page.

Figure 6.11a — Control Lag Times.

✔ NOTE

:

Cascade Low Range and Cascade High Range Set

Points for Input 1 (as shown above) are setup under Analog In-

put 3. Refer to Setup Chapter.

Figure 6.11b — Cascade Control.

Figure 6.11 — Cascade Example

Error Signal

(Heat)

0 to 100%

(Cool)

0 to -100%

Percent Power

0% to 100%

Set Point

(Process Part)

Input 3

Outer Loop

(Process Part)

Input 1

Inner Loop

(Energy Source)

Control Outer Loop

PID Set 1-5

ES/PB x 100 = % Out

Cascade Inner Loop

PID Set 1-5

ES/PB x 100 = % Out

0% = Cascade Low Range/Deviation

100% = Cascade High Range/Deviation

Error Signal

+

-

+

-

Outer Loop

Inner Loop

Time

Temperature

Curve A (PID)

Set

Point

Curve B (Cascade)

Curve C (Single-control)

input

1

input

3

output 1

limit

limit sensor

oil in

heater

oil out

inner-loop

thermocouple

Lube O il Ta nk

outer-loop

thermocouple

F

4

1

2

1B

1B

1A

1A

A

M

/