Multiple pid sets, Burst fire – Watlow Series F4S/D User Manual

Page 70

6 . 6

■

F e a t u r e s

Wa t l o w S e r i e s F 4 S / D

Multiple PID Sets

The Series F4 has five PID sets available for each

channel, sets 1 to 5 for Channel 1 and sets 6 to 10

for Channel 2, allowing optimal performance under

different conditions, loads and temperatures. In the

Static Set Point mode, PID Set 1 is used for Chan-

nel 1 and PID Set 6 is used for Channel 2 control.

When programming a profile, you can assign differ-

ent sets to each Ramp step and Soak step.

A PID set includes proportional, integral and

derivative settings for outputs A and B. It also in-

cludes dead band, as long as the proportional band

is not set to 0.

Location in software: Operations Page > Edit PID >

PID Set Channel x (1 or 2) > PID Set x (1 to 5) or

(6 to 10).

Channel 1 (Heat/Cool)

Output 1A Heat

Output 1B Cool

PID Sets 1 to 5

PropBand A

Integral A

Derivative A

Dead Band A

PropBand B

Integral B

Derivative B

Dead Band B

Channel 2 (Relative

Humidity)

Output 2A Humidify

Output 2B Dehumidify

PID Sets 6 to 10

PropBand A

Integral A

Derivative A

Dead Band A

PropBand B

Integral B

Derivative B

Dead Band B

Burst Fire

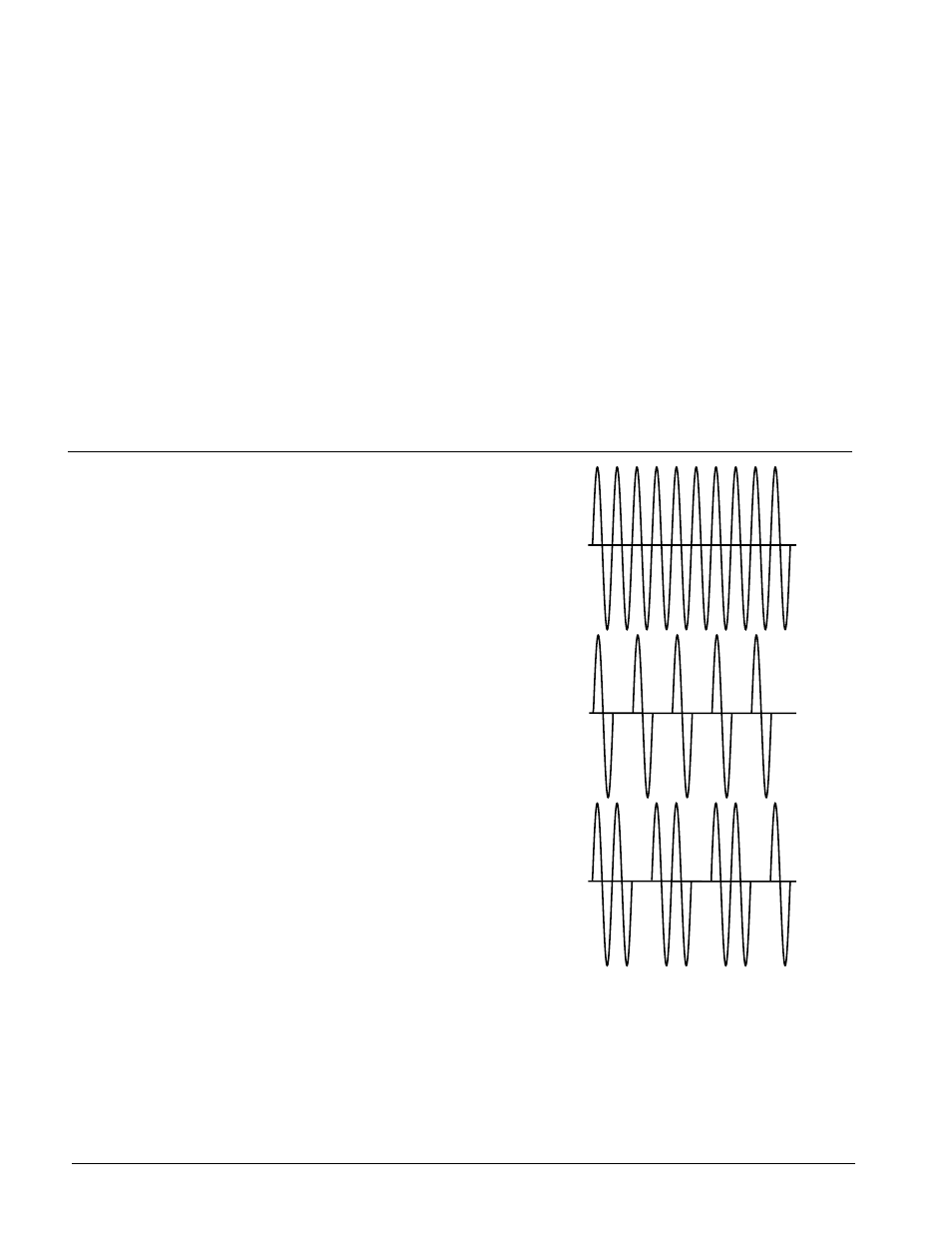

Burst firing provides even output power with the

lowest level of noise generation (RFI). Burst fire is

the preferred method for controlling a resistive

load, providing a very short time base for longer

heater life.

The controller determines when the ac sine wave

will cross the 0-volts point, then switches the load

on or off only at this point, minimizing RFI.

Location in software: Setup Page > Control Output

x (1 to 3).

Figure 6.6 — Burst Fire.

66% output

2 ON, 1 OFF

50% output

1 ON, 1 OFF

100% output

10 ON, 0 OFF