On/off control, Proportional control (p), Figure 4.1—on/off control 82 – Watlow CPC400 User Manual

Page 96

Chapter 4: Tuning and Control

CPC400 Series User’s Guide

82

Watlow Anafaze

Doc. 0600-2900-2000

On/Off Control

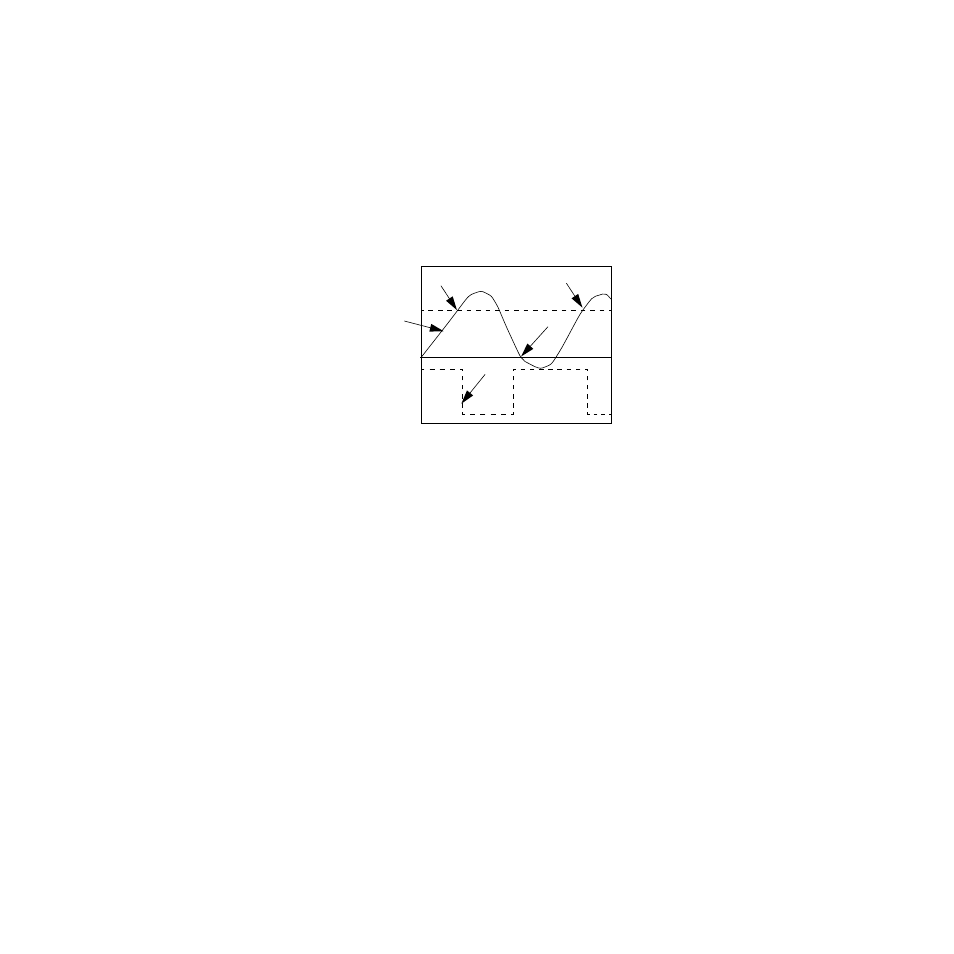

On/off control is the simplest way to control a process. The

controller turns an output on or off when the process vari-

able reaches limits around the desired set point. This limit

is adjustable.

For example, if the set point is 1000°F and the control hys-

teresis is 20°F, the heat output switches on when the pro-

cess variable drops below 980°F and off when the process

rises above 1000°F. A process using on/off control cycles

around the set point. Figure 4.1 illustrates this example.

Figure 4.1

On/Off Control

Proportional Control (P)

Proportional control eliminates cycling by increasing or de-

creasing the output proportionally with the process vari-

able’s deviation from the set point.

The magnitude of proportional response is defined by the

proportional band. Outside this band, the output is either

100 percent or 0 percent. Within the proportional band the

output power is proportional to the process variable’s devi-

ation from the set point.

For example, if the set point is 1000°F and the proportional

band is 20°F, the output power is as follows:

•

0 percent when the process variable is 1000°F or above

•

50 percent when the process variable is 990°F

•

75 percent when the process variable is 985°F

•

100 percent when the process variable is 980°F or be-

low

However, a process that uses only proportional control set-

tles at a point above or below the set point; it never reaches

the set point. This behavior is known as offset or droop.

When using proportional control, configure the manual re-

set parameter for the power level required to maintain set

point.

Heat Off

Heat On

Set Point

Set Point - Hysteresis

Process

On

Heat Off

Output

Off

Variable

980

°

F

1000

°

F