Input scaling example: 4 to 20 ma sensor, Figure 3.6—input scaling 59, Figure 3.6 , a 20 – Watlow CPC400 User Manual

Page 73

CPC400 Series User’s Guide

Chapter 3: Operation and Setup

Doc. 0600-2900-2000

Watlow Anafaze

59

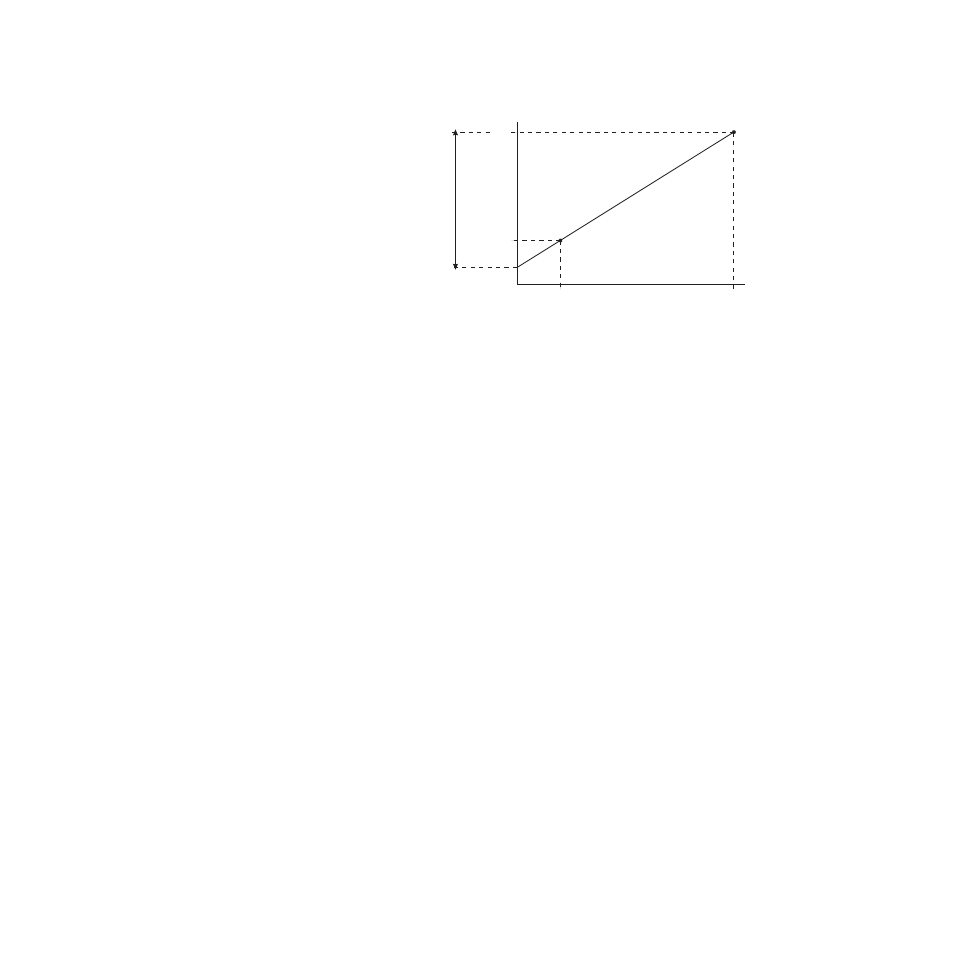

Figure 3.6

Input Scaling

The range for set points and alarms is bound by the process

variables that correspond to the 0 percent and 100 percent

input signals (or the 0 Hz and 2000 Hz signals for pulse in-

puts). Bear in mind that the range for set points and

alarms is not bound by the low and high process variable

ranges that you enter in the scaling parameters.

Input Scaling Example: 4 to 20 mA Sensor

Situation

Suppose the controller has a 0 to 20 mA process input that

is connected to a pressure sensor. The pressure sensor has

a range of 4 to 20 mA, representing 0.0 to 50.0 pounds per

square inch (PSI).

Setup

Set the scaling parameters in the Input menu as follows:

•

For the Input type parameter, choose process.

•

For the Disp format parameter, choose -999.9 to

3000.0, because the sensor measures PSI in tenths.

•

For the Input signal low and Input signal high param-

eters, use the minimum and maximum range of the

sensor. In this case, the sensor range is 4 to 20 mA.

The range must be expressed in percent of full scale.

To determine the percentages, divide the minimum

and maximum sensor range (4 mA and 20 mA) by the

maximum signal that the controller can accept (20

mA):

•

Input signal low = 4 mA/20 mA = 0.2 = 20%

0%

100%

20%

Input Signal

Pr

ocess V

ariab

le

8

28

Rang

e f

or set points and alarms