Input scaling example: pulse encoder – Watlow CPC400 User Manual

Page 75

CPC400 Series User’s Guide

Chapter 3: Operation and Setup

Doc. 0600-2900-2000

Watlow Anafaze

61

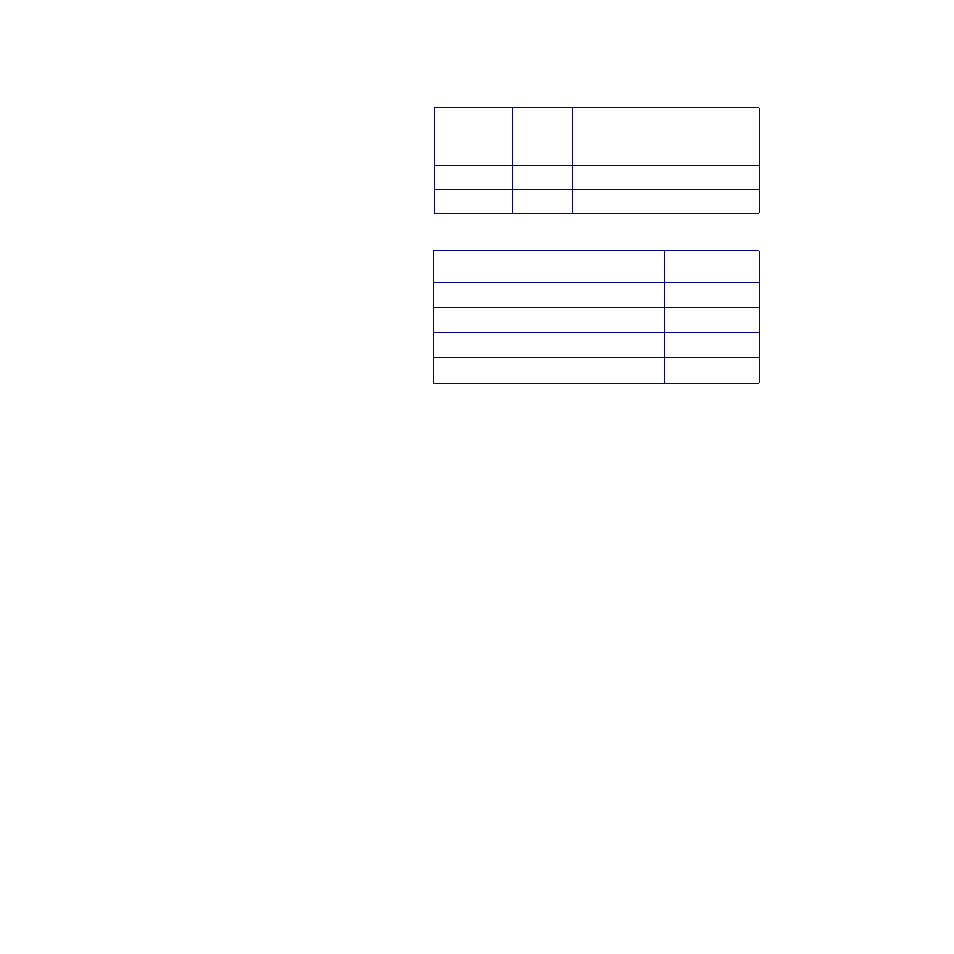

Table 3.6

Input Readings and Calculations

Table 3.7

Scaling Values

Input Scaling Example: Pulse Encoder

Situation

A pulse encoder measures the movement of a conveyor. The

encoder generates 900 pulses for every inch the conveyor

moves. You want to measure conveyor speed in feet per

minute (FPM).

Setup

The encoder input is connected to the pulse input (loop 5 on

a CPC404, loop 9 on a CPC408). On that loop, set the Input

type parameter to pulse.

Set the Input pulse sample parameter to 1 sec, because a

one-second sample time gives adequate resolution of the

conveyor speed. The resolution is 0.006 feet per

minute:

Since the resolution is in thousandths, the Disp format pa-

rameter is set to -9.999to 30.000.

To determine the settings for the Input low range and Input

high range parameters, calculate the process variable val-

ues when the input signal is 0 Hz and 2000 Hz. (You could

calculate the values at other frequencies.)

•

At 0 Hz, the process variable is 0.000 FPM.

•

At 2000 Hz, the process variable is 11.111 FPM:

Process

Variable

Displayed

Sensor

Input

Reading in

Percent of Full Scale

65 GPM

4.75 V

(4.75 V / 5.00 V) x 100% = 95%

3 GPM

0.5 V

(0.5 V / 5.00 V) x 100% = 10%

Parameter

Value

Input range high

65 GPM

Input high signal

95.0%

Input range low

3 GPM

Input low signal

10.0%

1 pulse

1 second

------------------------x

60 seconds

1 minute

-------------------------------x

1 inch

900 pulses

-----------------------------x

1 foot

12 inches

--------------------------

0.006 FPM

=