Setting up differential control, How to set up differential control, Setting up differential control 75 – Watlow CPC400 User Manual

Page 89: Figure 3.14—application using ratio control 75

CPC400 Series User’s Guide

Chapter 3: Operation and Setup

Doc. 0600-2900-2000

Watlow Anafaze

75

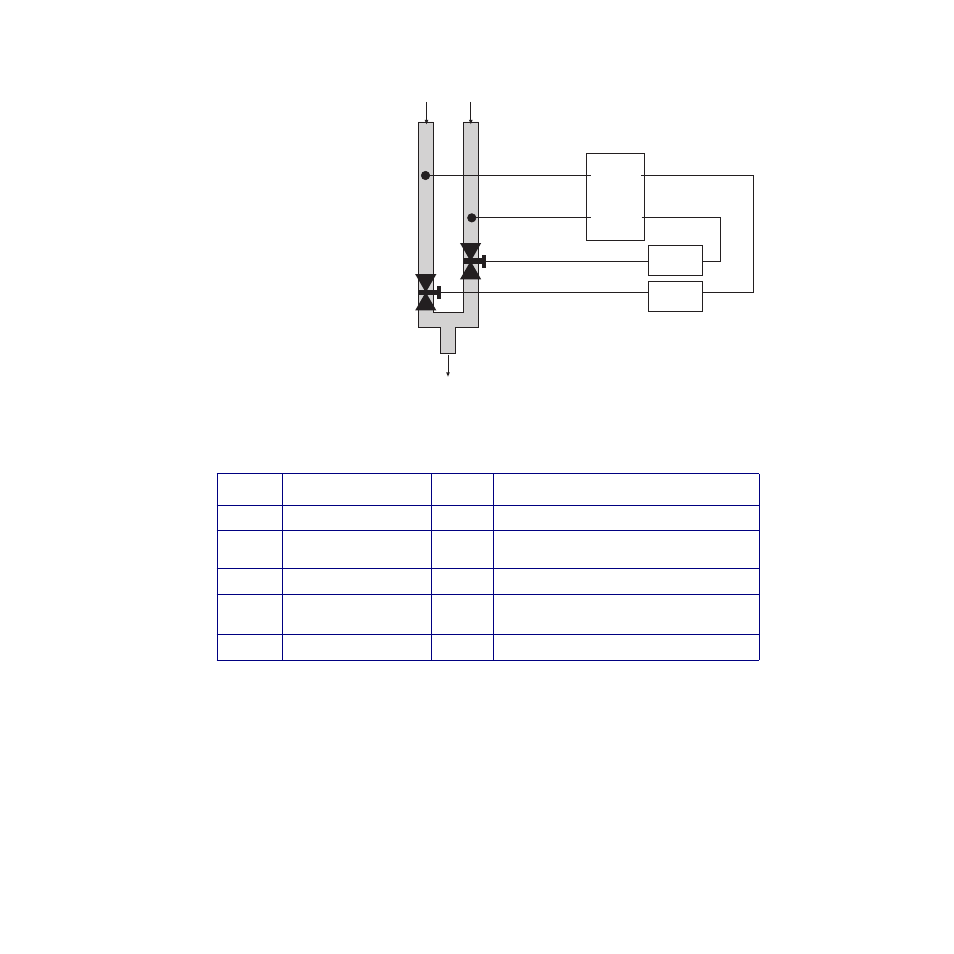

Figure 3.14 Application Using Ratio Control

Table 3.12

Ratio Control Settings for the Ratio

Loop (Loop 2) in the Example

Setting Up Differential Control

Differential control is a simple application of ratio control,

used to control one process (ratio loop) at a differential, or

offset, to another process (master loop).

How to Set Up Differential Control

Set up differential control as you would set up ratio control.

Set the Control ratio parameter to 1.0, and enter the de-

sired set point differential (offset) at the Ratio SP diff pa-

rameter.

Menu

Parameter

Value

Comment

Ratio

Ratio master loop

01

Loop 1 is the master loop.

Ratio

Ratio low SP

0.0

The minimum ratio loop set point is 0.0 gallons

per second (gps).

Ratio

Ratio high SP

7.0

The maximum ratio loop set point is 7.0 gps.

Ratio

Control ratio

0.5

The H

2

0 flow rate (10 gps) is multiplied by 0.5

to obtain the KOH flow rate (5 gps).

Ratio

Ratio SP diff

0

For this example, there is no set point differential.

CPC400

Loop 1 PID Output

Loop 2 PID Output

Loop 1 Input

Process Variable

Loop 2 Input

Process Variable

Motorized Control Valve 2

Motorized

Control

Valve 1

Mixture Output

Water Input

KOH Input

Flow

Transducer

Loop 1: Water Flow Control Loop

Loop 2: KOH Flow Control Loop

Serial

DAC

Serial

DAC