How to set up ratio control, Ratio control example: diluting koh, Set point of the ratio loop 74 – Watlow CPC400 User Manual

Page 88

Chapter 3: Operation and Setup

CPC400 Series User’s Guide

74

Watlow Anafaze

Doc. 0600-2900-2000

.

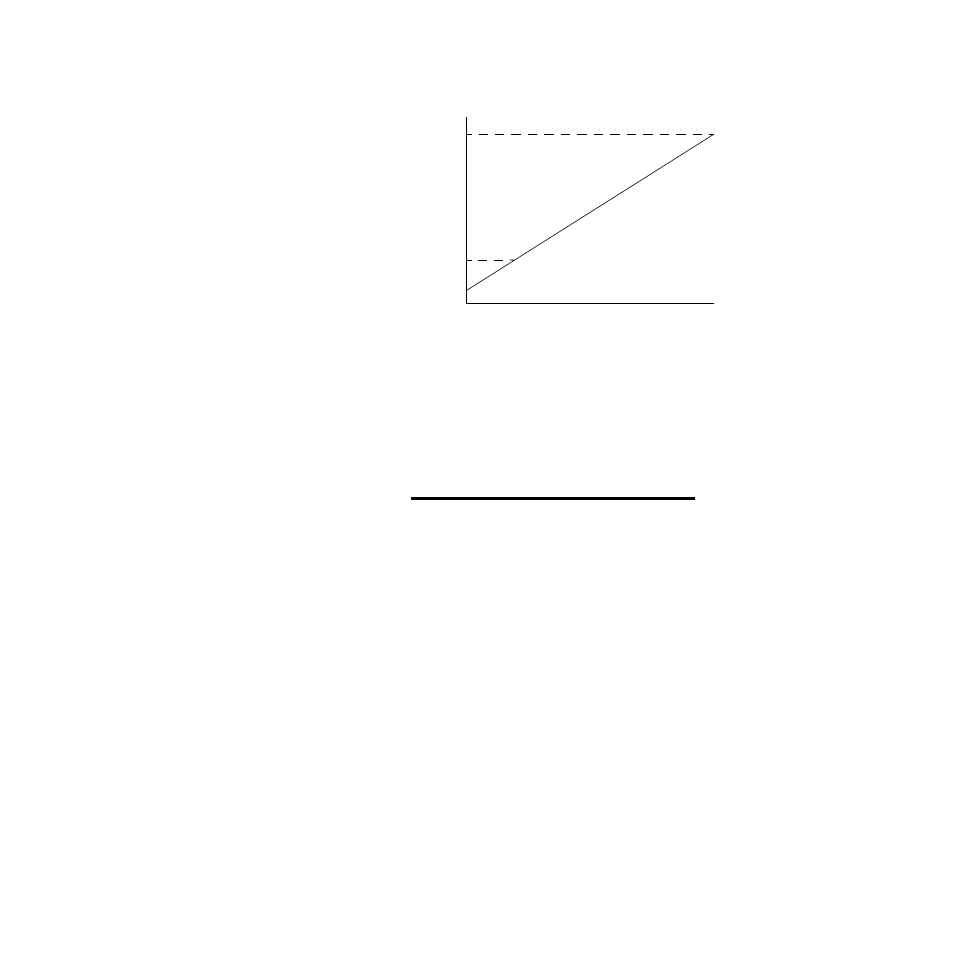

Figure 3.13 Relationship Between the Process

Variable on the Master Loop and

the Set Point of the Ratio Loop

NOTE!

Ratio control cannot be used on the same control

loop as cascade control.

How to Set Up Ratio Control

1.

Adjust and tune the master loop for optimal perfor-

mance before implementing the ratio setup.

2.

For the ratio loop, set the parameters in the Ratio

menu.

3.

Configure both the master loop and the ratio loop for

inputs, outputs, and alarms.

Ratio Control Example: Diluting KOH

A chemical process requires a formula of two parts water

(H

2

O) to one part potassium hydroxide (KOH) to produce

diluted potassium hydroxide. The desired flow of H

2

O is 10

gallons per second (gps), so the KOH should flow at 5 gps.

Separate pipes for each chemical feed a common pipe. The

flow rate of each feeder pipe is measured by a CPC400, with

H

2

O flow measured on loop 1 and KOH flow measured on

loop 2. The outputs of loops 1 and 2 adjust motorized

valves.

High SP

Low SP

Input Range

Input Range

Master PV * Control Ratio + SP Diff

erential

Ratio Loop Set P

oint

Master Loop Process Variable

SP Differential

SP = Set Point

PV = Process Variable

Low

High