Setting up ratio control, Setting up ratio control 73, Variable in cascade example 73 – Watlow CPC400 User Manual

Page 87

CPC400 Series User’s Guide

Chapter 3: Operation and Setup

Doc. 0600-2900-2000

Watlow Anafaze

73

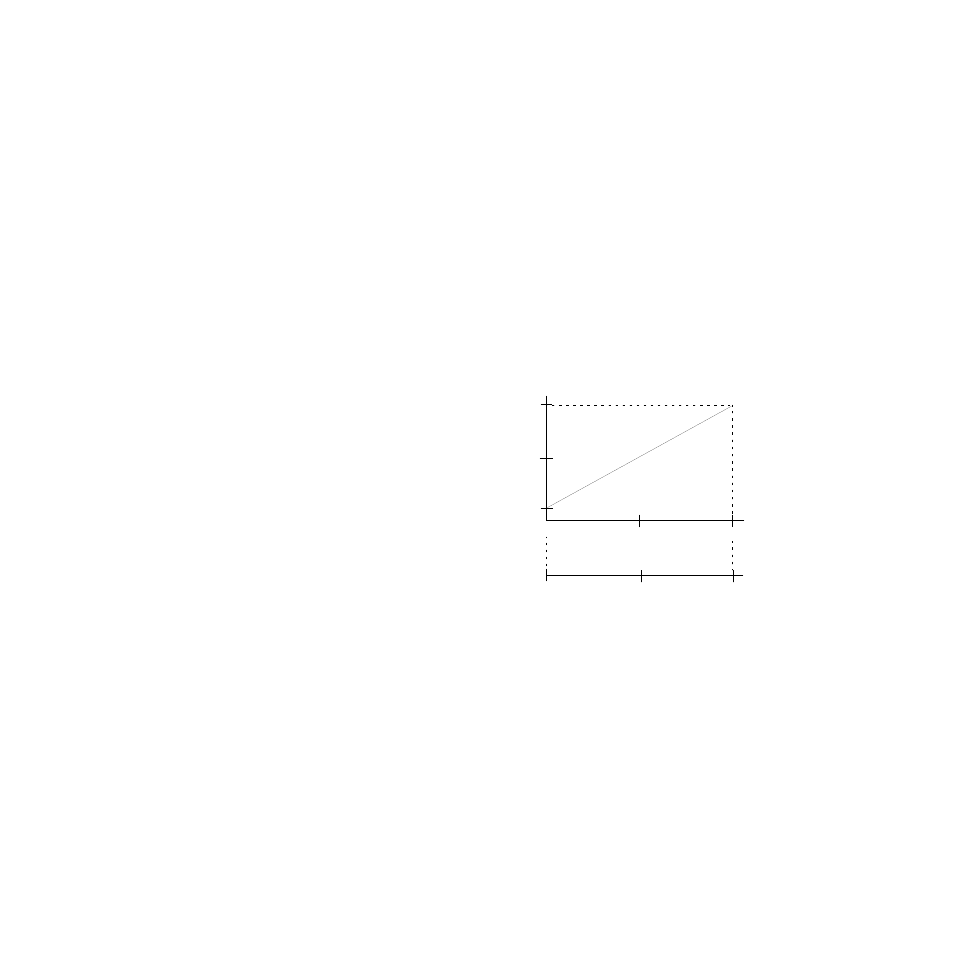

As the temperature in the middle of the tank (loop 1) drops,

the output goes up proportionally and the set point of loop

2 goes up proportionally. Thus heat is added to the system

at the element even though the temperature near the ele-

ment may have been at the desired temperature.

With proportional control, when loop 1 is at set point, its

output is 0 percent, and the set point of loop 2 is equal to

the desired temperature 150°F. If the temperature of the

loop 1 drops below 149°F, the deviation results in a propor-

tional output of 10 percent. This results in an increase to

the set point for loop 2 equal to 10 percent of the set point

range. In this case the range is 40°F (190 - 150°F = 40°F),

and 10 percent of 40°F is 4°F.

So when the temperature at loop 1 drops 1°F, the set point

of loop 2 increases by 4°F until the output of loop 1 is 100

percent and the set point of loop 2 is 190°F. At this point,

further decreases of the loop 1 process variable have no ad-

ditional affect on loop 2. Figure 3.12 illustrates this rela-

tionship.

Figure 3.12 Relationship of Secondary Loop

Set Point to Primary Loop Process

Variable in Cascade Example

Setting Up Ratio Control

Ratio control allows the process variable of one loop (mas-

ter loop), multiplied by a ratio, to be the set point of another

loop (ratio loop). You can assign any process variable to de-

termine the set point of a ratio loop.

By adjusting the ratio control parameters, you can adjust

the influence that the master loop process variable has on

the set point of the ratio loop

Set P

oint of the Secondar

y Loop

(Engineer

ing Units)

Process Variable of Primary Loop (ºF)

Heat Output of Primary Loop

(Percent of Full Scale)

0%

50%

100%

150ºF

145ºF

140ºF

190ºF

170ºF

150ºF