Setting up cascade control, How the secondary set point is determined, Setting up cascade control 69 – Watlow CPC400 User Manual

Page 83

CPC400 Series User’s Guide

Chapter 3: Operation and Setup

Doc. 0600-2900-2000

Watlow Anafaze

69

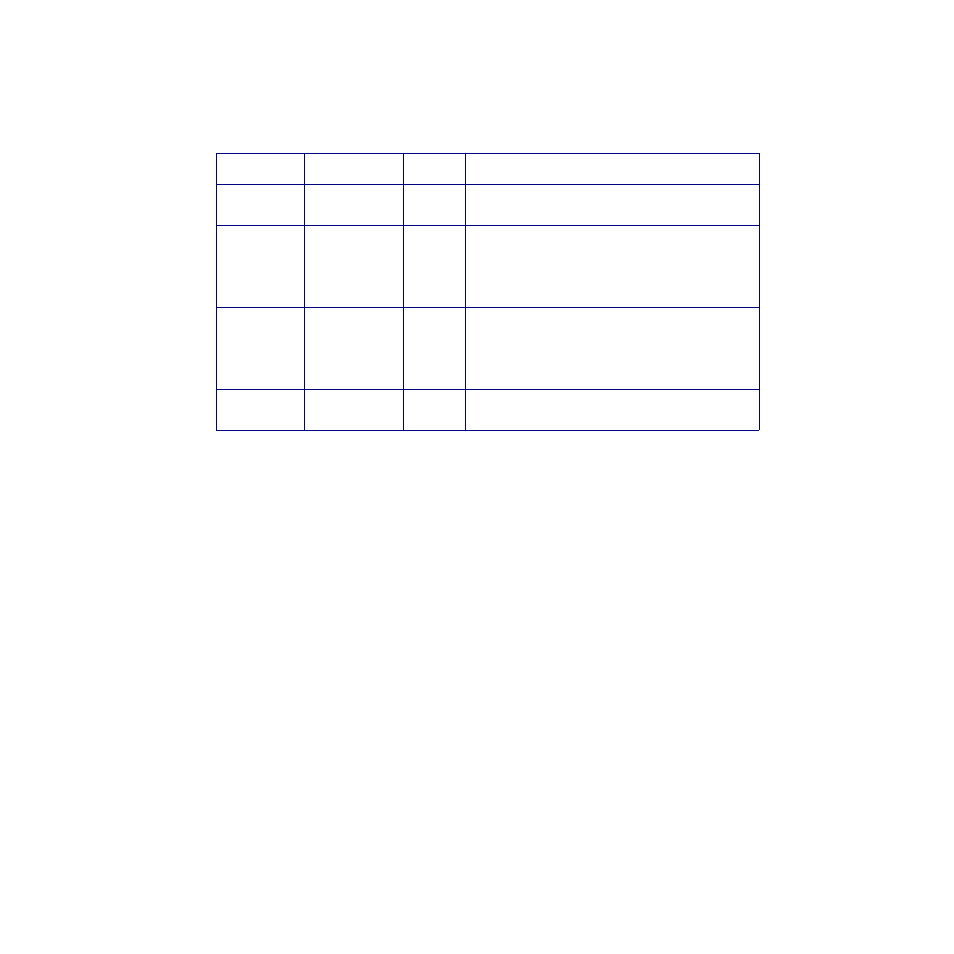

Table 3.9 shows the parameter setup for this example.

Table 3.9

Parameters Settings for Process

Variable Retransmit Example

To complete this configuration, the output for loop 2 must

be configured to provide the 4 to 20 mA analog signal (via

the Serial DAC) that is required by the data logger.

When setup is completed, the controller will produce an

output on loop 2 which is linear and proportional to the loop

1 process variable.

Setting Up Cascade Control

Cascade control is used to control thermal systems with

long lag times, which cannot be as accurately controlled

with a single control loop. The output of the first (primary)

loop is used to adjust the set point of the second (secondary)

loop. The secondary loop normally executes the actual con-

trol.

Some applications, such as aluminum casting, use two-

zone cascade control where the primary output is used for

the primary heat control and the cascaded output is used

for boost heat. You can use the primary heat output for

both control and for determining the set point of the sec-

ondary loop.

How the Secondary Set Point is Determined

The set point of the secondary loop is determined according

to the heat and cool output values from the primary loop

and user-specified cascade parameters:

Menu

Parameter

Value

Comment

PV retrans

Ht output

retrans

PV 1

Choose to retransmit the loop 1 process variable.

PV retrans

Ht retrans

LowPV

0˚F

This is the input value represented by a 0 percent

output signal. The recorder input is a linear 4 to 20

mA signal representing a range of 0 to 1000°F, so

we will use a 0 percent output signal to represent

0°F.

PV retrans

Ht retrans

HighPV

1000˚F

This is the input value represented by a 100 percent

output signal. The recorder input is a linear 4 to 20

mA signal representing a range of 0 to 1000°F, so

we will use a 100 percent output signal to represent

1000°F.

PV retrans

Cl output

retrans

none

Not using the cool output of loop 2 to retransmit a

process variable.