Essential safety precautions, Safety icons, System design – Proface AGP3500 - 10.4 DIO HMI" User Manual

Page 3

2

Essential Safety Precautions

All safety-related procedures stated in this document must be followed to operate the GP correctly and safely. Be sure to

read this and any related documents thoroughly to understand the correct operation and functions of the GP unit.

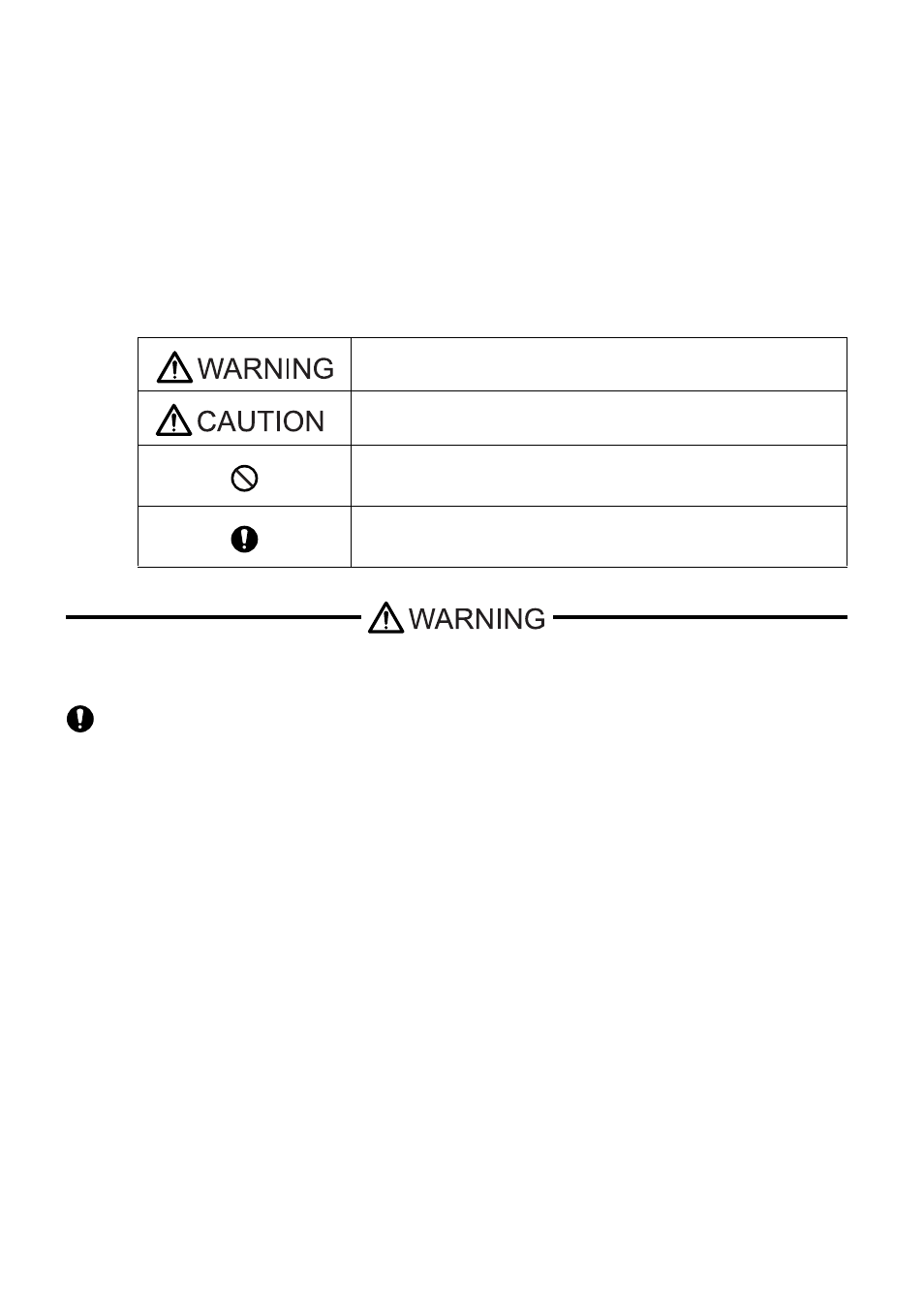

Safety Icons

Throughout this manual, these icons provide essential safety information for GP operation procedures requiring special

attention. These icons indicate the following levels of danger:

System Design

Indicates situations where severe bodily injury, death or major equipment

damage can occur.

Indicates situations where slight bodily injury or minor equipment dam-

age can occur.

Indicates actions or procedures that should NOT be performed.

Indicates actions or procedures that MUST be performed to ensure cor-

rect unit operation.

Be sure to design your GP control system so that, in the event of a main power supply failure or a GP acci-

dent, the user system’s overall safety integrity will be maintained. If this is not done, incorrect output sig-

nals or a GP malfunction may cause an accident.

1) Interlock and other circuits designed to interrupt or oppose normal machine movement (such as Emer-

gency Stop, General Protection, and forward and reverse rotation), as well as those designed to pre-

vent machine damage (such as upper, lower, and traverse movement limit positioning) should all be

designed to be located outside of the GP.

2) When the GP generates a “Watchdog Timer Error” during logic program operating, the logic program

operation will halt. Also, when Errors occur in Input/Output control areas that the GP cannot detect,

unexpected movement may occur in those areas. Therefore, and to prevent unsafe machine move-

ment, a “Failsafe Circuit” should be created which is completely external to the GP.

For a failsafe circuit, refer to “Installation Precautions” (page 8-15).

3) If a problem arises with an external unit’s relay or transistor, causing an output (coil) to remain either

ON or OFF, a major accident can occur. To prevent this, be sure to set up external watchdog circuits

that will monitor vital output signals.

- AGP3400 - 7.5 DIO HMI" AGP3300 - 5.7 DIO HMI" AGP3600 - 12.1 FLEX Network HMIs" AGP3500 - 10.4 FLEX Network HMI" AGP3400 - 7.5 FLEX Network HMI" AGP3600 - 12.1 CANopen HMI" AGP3500 - 10.4 CANopen HMI" AGP3400 - 7.5 CANOpen HMI" AGP3300 - 5.7 CANopen HMI" AGP3300H - 5.7 Handheld HMIs" AGP3750 - 15 Multi-Media HMI" AGP3650 - 12.1 Multi-Media HMIs" AGP3550 - 10.4 Multi-Media HMIs" AGP3450 - 7.5 Multi-Media HMI" AGP3360 - 5.7 Multi-Media HMI" AST3300 - 5.7 Basic HMI" AST3200 - 3.8 Basic HMI" AGP3600 - 12.1 Standard HMIs" AGP3500 - 10.4 Standard HMIs" AGP3400 - 7.5 Standard HMI" AGP3300 - 5.7 Standard HMI" AGP3200 - 3.8 Standard HMI"