Noise elimination measures and grounding, 3 noise elimination measures and grounding – IAI America SCON-C User Manual

Page 42

24

3.3 Noise Elimination Measures and Grounding

The following explains the noise elimination measures that should be taken when using this controller.

(1) Wiring and power connection

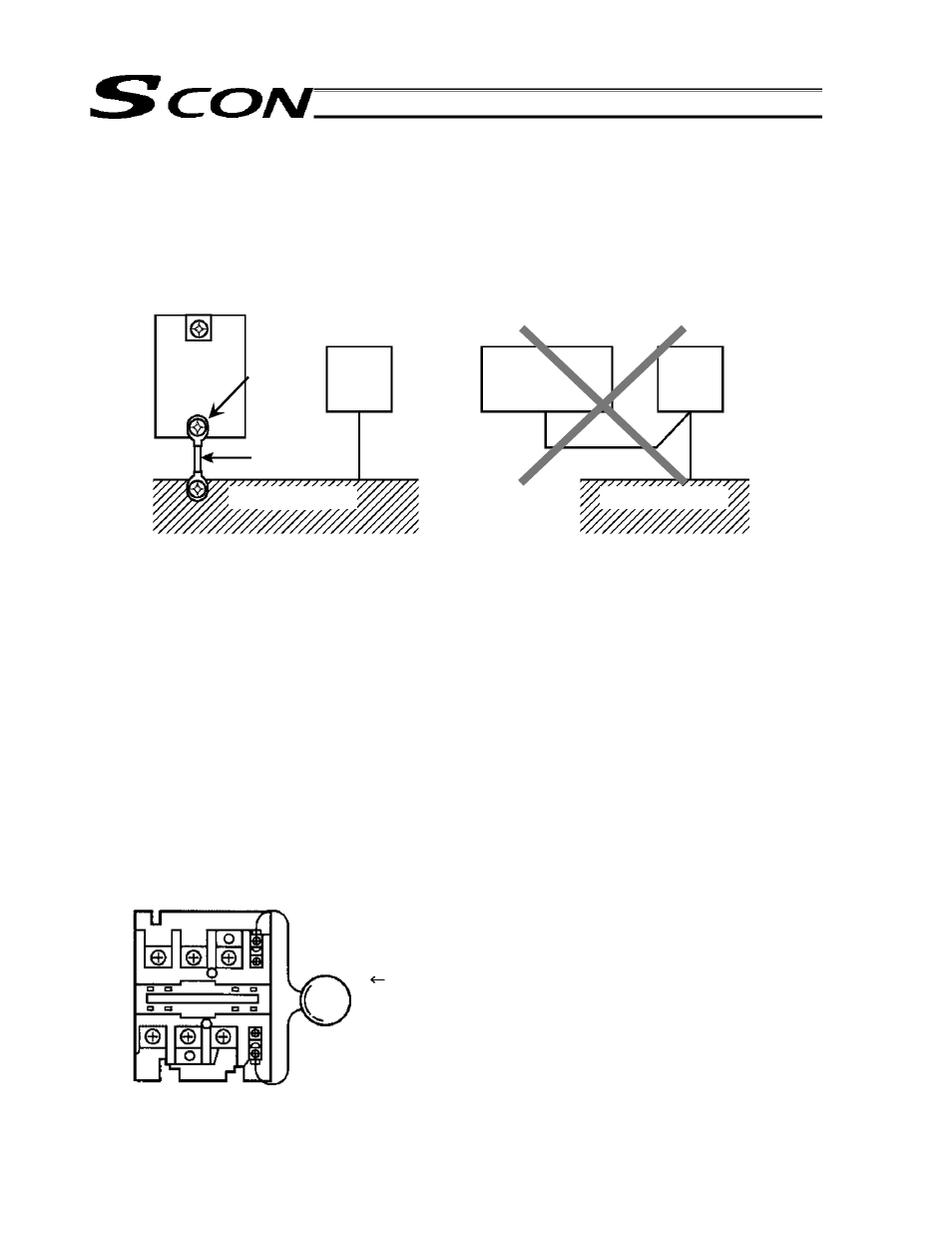

[1] Provide dedicated class-D grounding (former class-3 grounding: Grounding resistance 100

or less) using

a grounding wire with a size of 1.6 mm

2

or larger.

[2] Cautions on wiring method

Separate the controller wiring from high-power lines of motive power circuits, etc. (Do not tie them together

or place in the same cable duct.)

If the supplied motor or encoder cable is to be extended, consult IAI’s Engineering Service Section or Sales

Engineering Section.

(2) Noise sources and elimination

Noise generates from many sources, but the most common sources of noise you should consider when

designing a system are solenoid valves, magnet switches and relays. Noise generation from these components

can be prevented by the method explained below.

[1] AC solenoid valves, magnet switches, relays

Method --- Mount a noise killer in parallel with the coil.

Noise killer

Connect to each coil over the shortest possible wiring distance.

When a surge absorber is installed on the terminal block, etc., its

noise elimination effect will decrease if the distance from the coil

is long.

Controller

Other

equip-

ment

Controller

Other

equip-

ment

Class-D grounding

(Former class-3 grounding:

Grounding resistance 100

or less)

Attach the

grounding

wire to the

mounting

screw of the

main unit.

Connect a cable of

the largest possible

size over the shortest

possible distance

Grounding terminal

Grounding terminal

Ground the grounding wire for each controller:

do not share with or connect to other equipment.