IAI America SCON-C User Manual

Page 231

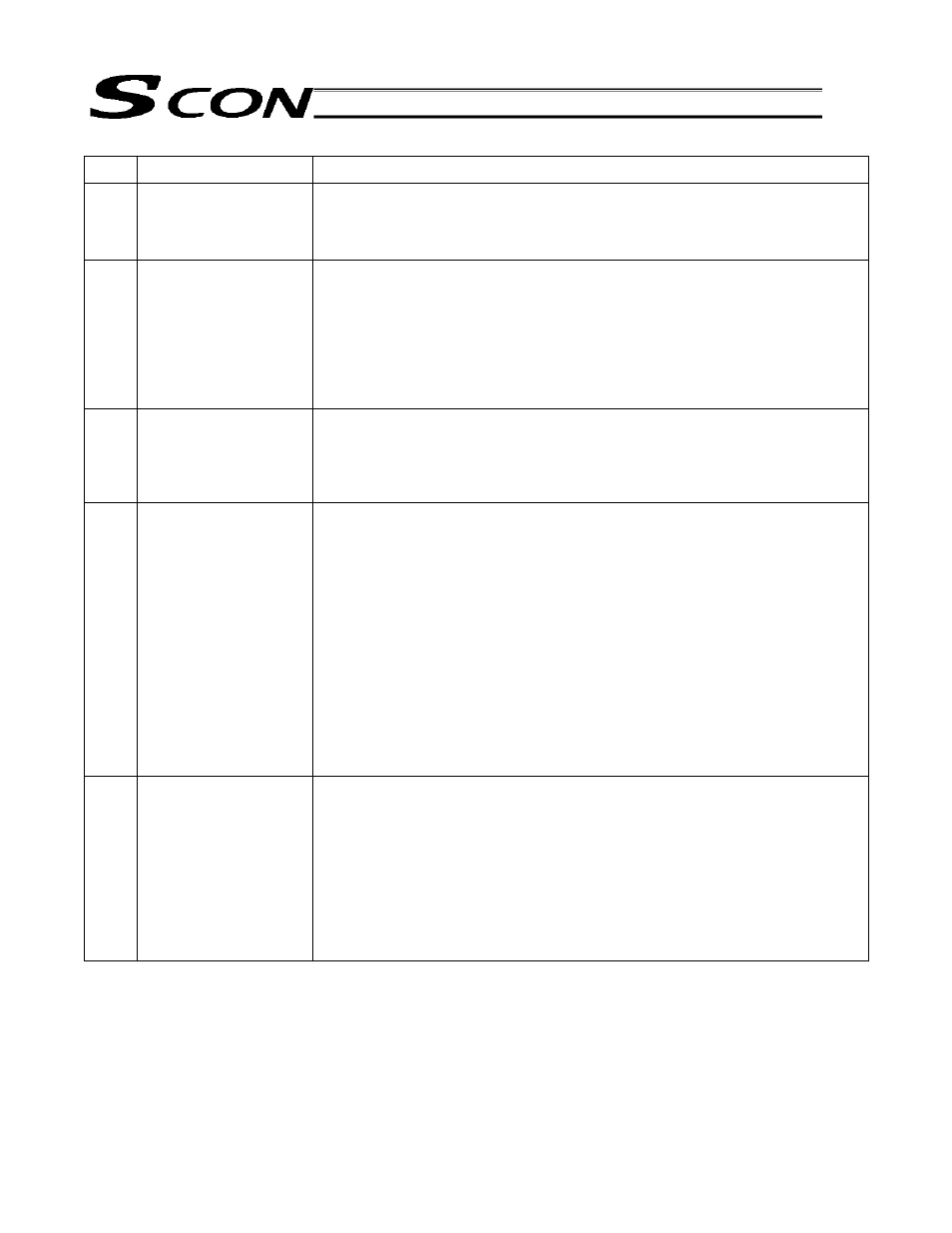

213

Appendix

Code Error

name

Cause/Action

0B5 Phase Z position error

The position where phase Z was detected at home return was outside the

specified range.

Cause: Encoder

failure

Action: Please

contact

IAI.

0BA Home

sensor

not

detected

This error indicates that the actuator equipped with the home check sensor has

not yet successfully completed the home return operation.

Cause: [1] The load contacted any surrounding equipment or structure during

home return.

[2] The slide resistance of the actuator is high in some location.

[3] The home check sensor is not properly installed, faulty or open.

Action: If the load is not contacting any surrounding equipment or structure,

[2] or [3] is suspected. Please contact IAI.

0BE Home return timeout

Cause: Home return does not complete after elapse of the time set by the

applicable manufacturer’s parameter following the start of home return

operation. (This error does not occur in normal operations.)

Action: The controller and actuator combination is wrong, among others.

Please contact IAI.

0BF Creep sensor not

detected

This error indicates during home return operation using a creep sensor a

home-sensor detection signal was output or mechanical end was reached

before a creep sensor signal was detected (or the actuator cannot move due to

an excessive load).

Cause: [1] Signal is not detected because the creep sensor is not installed in

an appropriate position.

[2] The cable is disconnected or the connector is not plugged in

properly.

[3] The load is receiving an external force.

Action: [1] Readjust the sensor installation position.

[2] Perform continuity check to see if the cable is disconnected. Also

check if the connector is plugged in properly.

[3] Review the mechanisms around the load and prevent the load from

receiving any strong external force.

If the cause cannot be specified, contact IAI.

0C0 Excessive actual speed Cause: The motor speed exceeded the maximum level set by the applicable

manufacturer’s parameter. Although this error does not occur in

normal operations, it may occur if the load decreased before a servo

error was detected and the actuator moved quickly as a result, which

can be caused by various reasons including the following:

[1] The slide resistance of the actuator is high in some location.

[2] The load increased due to momentary application of external force.

Action: Check the assembly condition of mechanical parts for any

abnormality.

If the actuator itself is suspected as the cause, please contact IAI.