IAI America SCON-C User Manual

Page 232

214

Appendix

Code Error

name

Cause/Action

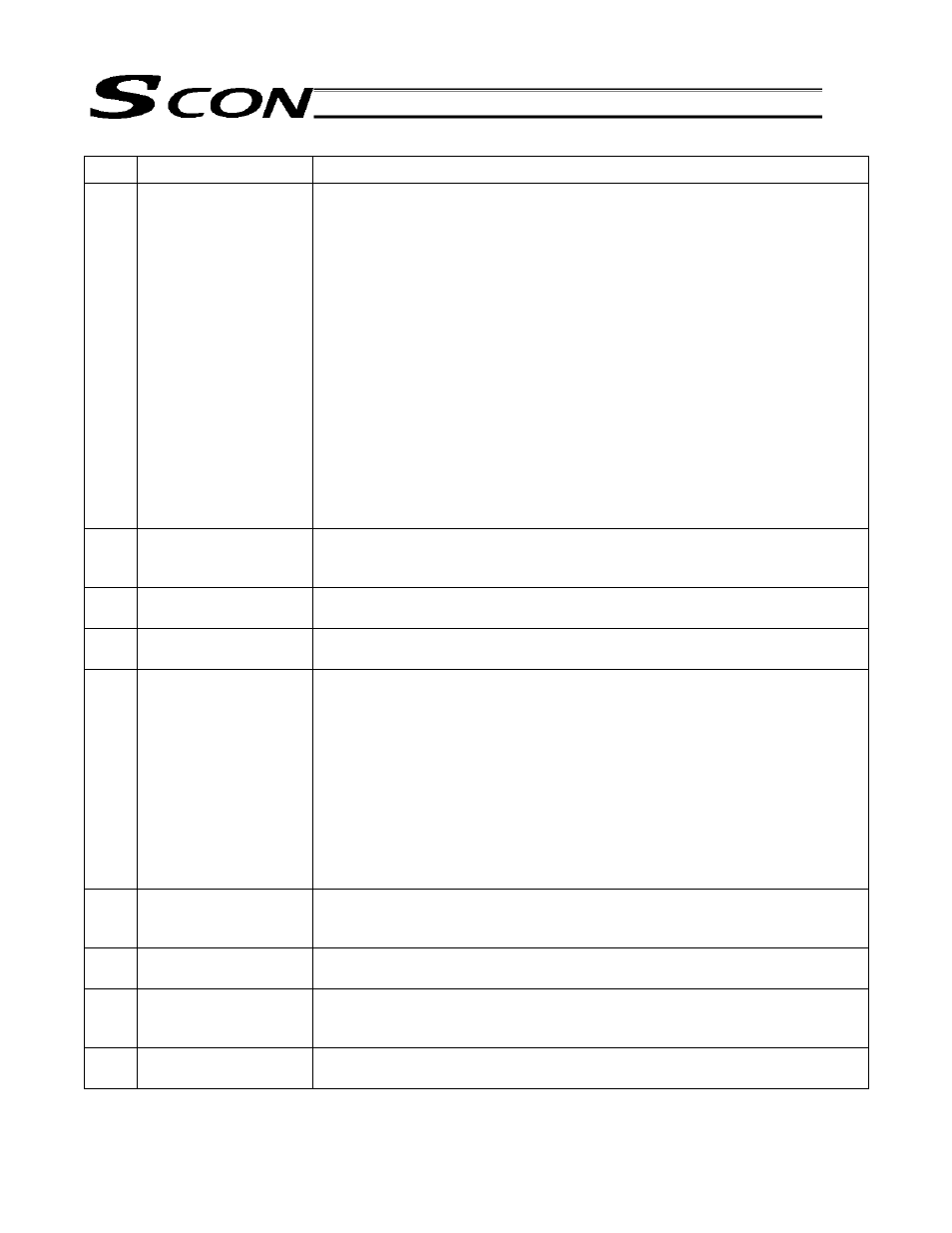

0C2 Overrun sensor signal

detected

This error indicates that a signal from the OT sensor installed at a mechanical

end was detected.

Cause: [1] The actuator was moved by hand or received an external force

while the servo was off (normal detection).

[2] The actuator was jogged in a condition where the home

coordinates were not yet established and thus the soft stroke

check did not function correctly (normal detection).

[3] The home position achieved by home return is not correct, or in the

case of an absolute type controller the coordinates have shifted

due to an inappropriate absolute reset position.

[4] The sensor characteristics do not match the setting of sensor

parameter No. 19, or the sensor is wired wrongly.

[5] The controller and actuator combination is wrong, or the soft limit

or screw lead set in the controller is not appropriate.

Action: If [1] or [2] is suspected, move the actuator in the opposite direction by

hand.

If this error occurred inside the effective stroke range, [3], [4] or [5] is a

likely cause. Check the home position, parameter setting, wiring, etc.

If the cause cannot be specified, contact IAI.

0CF 24-V I/O power error

Cause: The 24-V PIO power supply is abnormal.

Action: Turn on the 24-V PIO power first, and then turn on the controller

power.

0D2 Motor

power-supply

voltage excessive

Supported version: Up to V001A

Please refer to the cold start level code “0D2” for the detailed information.

0D3 Motor

power-supply

voltage low

Supported version: Up to V001A

Please refer to the cold start level code “0D3” for the detailed information.

0D8 Deviation overflow

The position deviation counter has overflowed.

Cause: [1] The speed dropped while the actuator was moving due to the

effect of an external force, etc.

[2] The excited-phase detection operation following the power on is

unstable.

[3] The power-supply voltage dropped.

Action: [1] Check the loading condition, such as whether the load is

contacting with any surrounding object or if the brake is released,

and remove the cause of the problem found.

[2] Since an overload condition is suspected, review the load weight.

Reconnect the power, and then perform home return.

[3] Check the power-supply voltage.

0D9 Software

stroke

limit

exceeded

Cause: After completion of home return, the current actuator position is

outside the software stroke limits.

Action: Move the actuator to a position inside the software stroke limits.

0DA Feedback pulse error

Cause: The feedback pulse data could no be output within the specified cycle.

Action: Implement noise elimination measures.

0DC Out of push & hold

operation range error

This error occurs when the actuator was pushed back to the target position due

to an excessive push force after completion of push & hold operation.

Review the entire system.

0F5 Nonvolatile

memory

write verification error

Supported version: Up to V001A

Please refer to the cold start level code “0F5” for the detailed information.