IAI America SCON-C User Manual

Page 234

216

Appendix

Code Error

name

Cause/Action

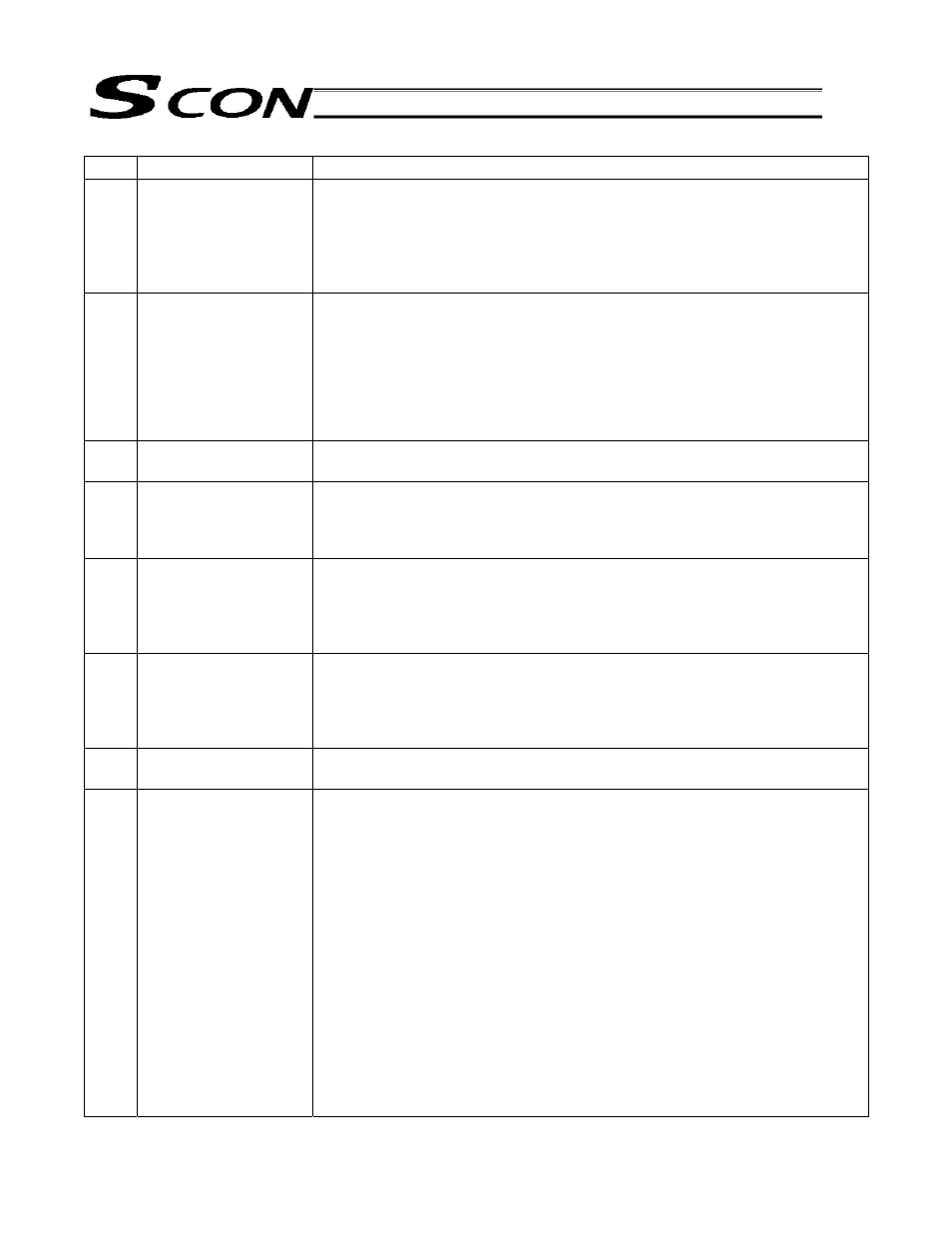

0CA Overheating

This error indicates that the temperature around the power transistor in the

controller is excessively high (95

C or above).

Cause: [1] The surrounding air temperature is high.

[2] A faulty part inside the controller.

Action: [1] Lower the surrounding air temperature.

[2] Add one or more regenerative boxes.

0CB Current-sensor

offset

adjustment error

When the controller is started, the condition of the current detection sensor in

the controller is checked during the initialization processing. This error indicates

that this sensor was found abnormal.

Cause: [1] The current detection sensor or any of its surrounding parts is

faulty.

[2] Inappropriate offset adjustment

Action: The board must be replaced or the offset must be adjusted. Contact

IAI.

0CD Emergency stop relay

fused

Cause: The emergency stop relay in the controller is fused.

Action: The relay or controller must be replaced. Contact IAI.

0CE Control

power-supply

voltage low

Cause: [1] The AC power-supply voltage is low.

[2] A faulty part inside the controller.

Action: Check the input power-supply voltage.

If the voltage is normal, please contact IAI.

0D2 Motor

power-supply

voltage excessive

Supported version: V001B~

Cause: [1] The input power-supply voltage of the motor is high.

[2] Faulty component in the controller

Action: Check the input power-supply voltage of the motor.

If the voltage is normal, please contact IAI.

0D3 Motor

power-supply

voltage low

Supported version: V001B~

Cause: [1] The motor input voltage is low.

[2] Faulty component in the controller

Action: Check the power-supply input voltage of the motor.

If the voltage is normal, please contact IAI.

0D7 Belt-breaking

sensor

detected

Cause: The belt of the ultra-high thrust RCS2-RA13R was broken.

Action: Contact IAI to arrange for belt replacement.

0E0 Overload

Cause: [1] The load increased due to application of external force.

[2] If the actuator is equipped with a brake, the brake cannot be

released.

[3] The sliding resistance of the actuator is large in some areas.

Action: [1] Check the load and its surrounding area. If the load is receiving an

abnormal external force, make the necessary correction to remove

the external force.

[2] Turn on the brake release switch to see if the brake is released. If

the brake is not released, the brake itself may be faulty, cable may

be disconnected, or there may be a faulty brake circuit component

in the controller, among others.

[3] If the load can be moved by hand, move the load to check if the

sliding resistance increases at a given point.

If [2] or [3] is suspected, contact IAI.

Caution: Be sure to remove the cause of the error before resuming the

operation. If the power was cut off, wait for at least 30 minutes

before turning on the power to prevent the motor coil from burning.