Parameters, Parameter settings required for operation, 1 parameter settings required for operation – IAI America SCON-C User Manual

Page 180: 1 basic settings

162

5. Parameters

5.1 Parameter Settings Required for Operation

Parameters can be set or changed using the teaching pendant or PC software.

After a parameter has been changed, the new setting will become effective once a “software reset” is performed

using the teaching pendant or PC software or the power is reconnected.

5.1.1 Basic

Settings

The parameters that must be set before the actuator can be operated are explained below.

(The following parameters are all you need to set, if the actuator performs only positioning operation.)

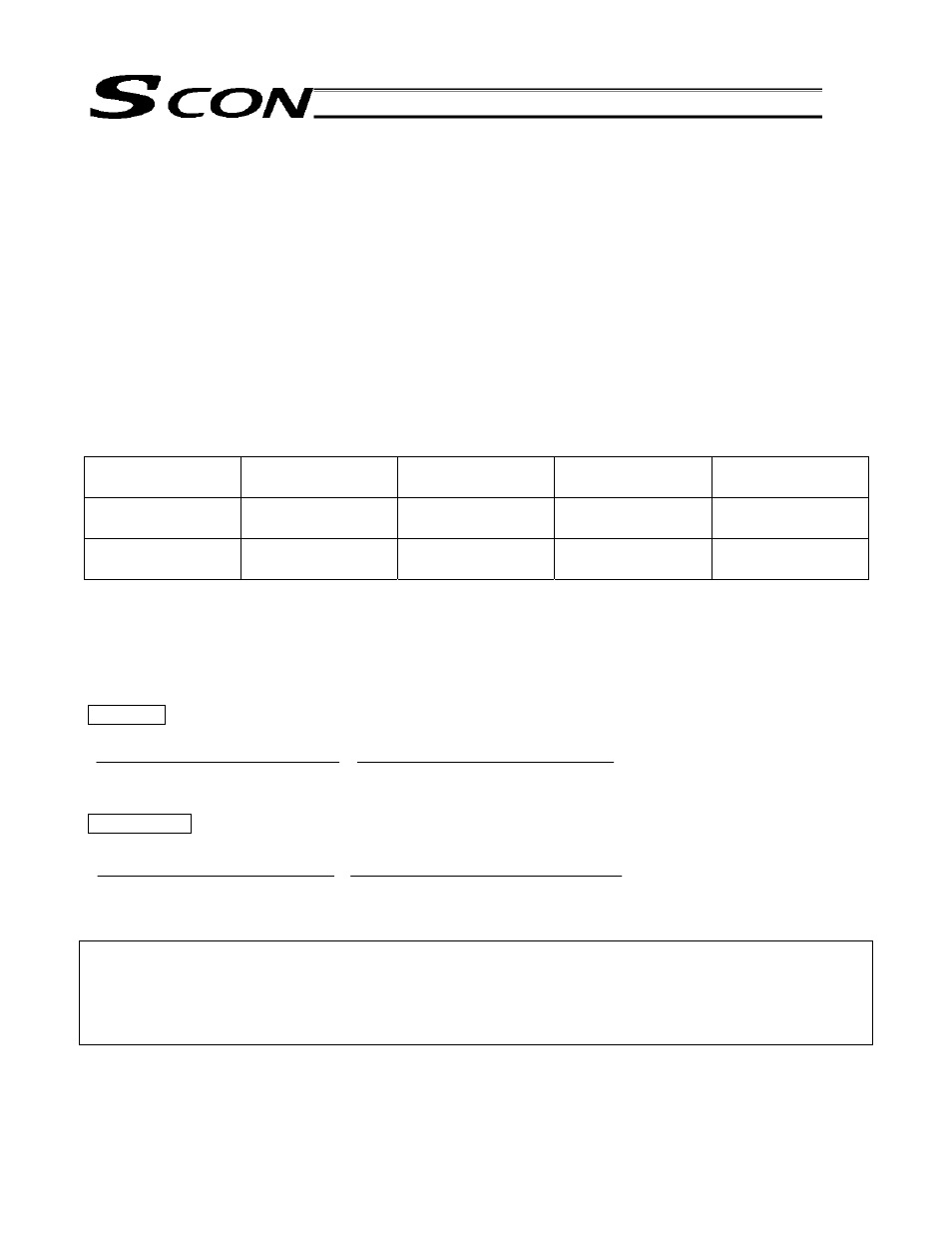

(1) Electronic

gear

User parameter Nos. 65/66, “Electronic gear numerator/denominator”

Name Symbol Unit Input

range

Default setting

(reference)

Electronic gear

numerator

CNUM -

1

to 4096

2048

Electronic gear

denominator

CDEN -

1

to 4096

125

These parameters are used to determine the unit travel distance of the actuator per each command pulse-train

input pulse.

Unit travel distance for linear axis = Minimum travel unit (1, 0.1, 0.01 mm, etc.) per pulse

Unit travel distance for rotational axis = Minimum travel unit (1, 0.1, 0.01 deg, etc.) per pulse

Electronic-gear calculation formula

Linear axis

Rotational axis

Reference

The actuator speed is calculated by the formula below:

Speed = Unit travel distance x Input pulse frequency (Hz)

Take note that setting the unit travel distance too small may prevent the actuator from reaching the maximum

speed in certain conditions.

(mm/pulse)

distance

travel

Unit

(mm/rev)

lead

screw

Ball

v)

(pulses/re

pulses

encoder

of

Number

(CDEN)

r

denominato

gear

Electronic

(CNUM)

numerator

gear

Electronic

)

(deg/pulse

distance

travel

Unit

axis

rotational

of

ratio

Gear

(deg/rev)

360

v)

(pulses/re

pulses

encoder

of

Number

(CDEN)

r

denominato

gear

Electronic

(CNUM)

numerator

gear

Electronic