178 appendix – IAI America SCON-C User Manual

Page 196

178

Appendix

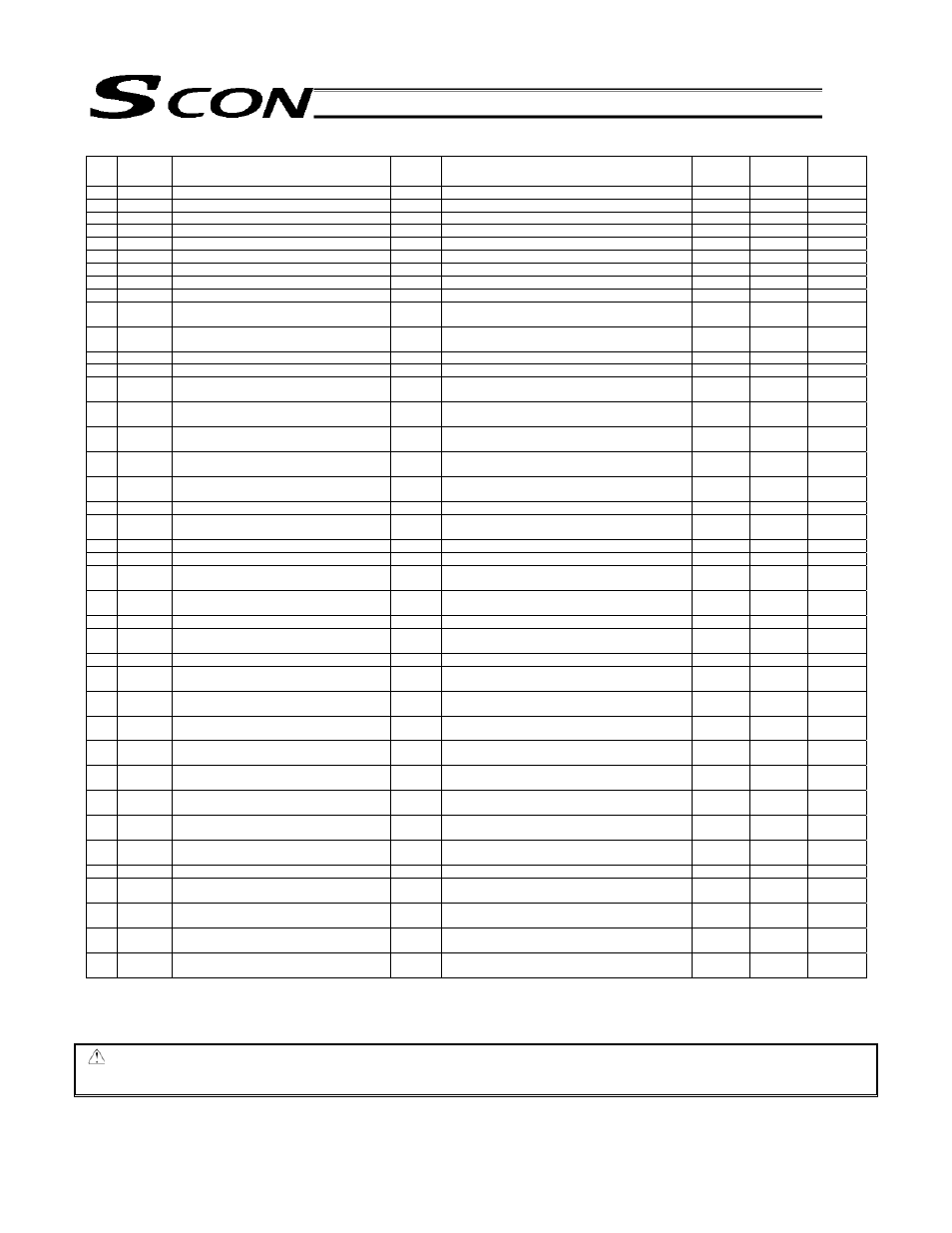

No. Category

Name

Unit

Default

factory

setting

Positioner

mode

parameter

Pulse-train

mode

parameter

Remarks

42

b

Enable function [0: Enable / 1: Disable]

-

1 [Disable]

45

c

Silent interval multiplier

time

0 [Do not apply multiplier]

46 b

Speed

override

%

100

47

b

PIO jog speed 2

mm/sec

100

48 b

PIO

inching

distance

mm

0.1

49

b

PIO inching distance 2

mm

0.1

50

b

Load output judgment time

msec

255

52

b

Default acceleration/deceleration mode

-

0 [Trapezoid]

53

b

Default standstill mode

-

0

54 d

Current-control

band

number

-

Set individually in accordance with the actuator

characteristics.

55 b

Position-command primary filter time

constant

msec

0

56 b

S-motion

ratio

setting

%

0

57 g

Torque-limiting

value

[%]

%

70

58 g

Deviation clear at servo OFF & alarm

stop [0: Disable / 1: Enable]

- 1

59 g

Deviation error monitor during torque

limiting [0: Disable / 1: Enable]

- 0

60 g

Deviation counter clear input

[0: Enable / 1: Disable]

- 0

61 g

Torque limit command input

[0: Enable / 1: Disable]

- 0

62 g

Pulse count direction

[0: Forward / 1: Reverse]

-

Set individually in accordance with the actuator

characteristics.

63

g

Command pulse input mode

-

1

64 g

Command-pulse input mode polarity [0:

Positive / 1: Negative]

- 0

65 g

Electronic

gear

numerator

-

2048

66 g

Electronic

gear

denominator

-

125

67 g

Forced stop input

[0: Enable / 1: Disable]

- 0

68 g

Feedback pulse output

[0: Enable / 1: Disable]

- 1

69 g

Feedback

pulse

pattern

-

0

70 g

Feedback pulse pattern polarity

[0: Positive / 1: Negative]

- 0

71 d

Feed-forward

gain

-

0

72 f

Timer period for emergency-stop relay

fusing monitor

msec

3000

73

f

Encoder voltage level

-

(In accordance with the specification at the time

of order)

74 f

PIO power monitor

[0: Enable / 1: Disable]

- 0

[Enable]

75 f

Electromagnetic-brake power monitor [0:

Disable / 1: Enable]

-

Set individually in accordance with the actuator

characteristics.

76

f

Belt-breaking sensor input polarity

-

Set individually in accordance with the actuator

characteristics.

77

b

Ball screw lead

mm

Set individually in accordance with the actuator

characteristics.

78

e

Axis operation type

-

Set individually in accordance with the actuator

characteristics.

79

e

Rotational axis mode selection

-

Set individually in accordance with the actuator

characteristics.

80

e

Rotational axis shortcut selection

-

0

88

a

Software limit margin

mm

Set individually in accordance with the actuator

characteristics.

89 b

Allowable time of exceeding torque

allowing continuous push & hold

sec

Set individually in accordance with the actuator

characteristics.

91 b

Current limit value at stopping due to

missed push & hold

-

0 [Current limit value during movement]

139 a Home

preset

mm

Set individually in accordance with the actuator

characteristics.

(Note) The numbers are displayed in the PC software, but not on the teaching pendant. Skipped numbers are not used and therefore omitted.

The classification codes are provided for the sake of convenience and are not displayed either in the PC software or on the teaching pendant.

(Note) For the pulse-train mode parameters corresponding to Nos. 57 to 70, refer to 5.2, “Effective Parameters in the Pulse-train Mode.” For all other

parameters, refer to 3.2, “Detail Explanation of Parameters” on the following pages in this Appendix.

Caution: When controlling the SCON controller via serial communication, always set the controller in the “positioner mode” (piano switch 1: OFF).

If it happens to be in the “pulse-train mode” by mistake, the SCON controller may operate erratically because it is operated according to

the “pulse-train mode” parameters.