7 greasing the ball screw (slider type) – IAI America ERC2 User Manual

Page 171

10. Maintenance and Inspection

148

10.7 Greasing the Ball Screw (Slider Type)

(1) Applicable grease

The following special grease is applied to the ball screw prior to shipment:

Kyodo Yushi

Multemp LRL3

This grease generates less heat and has other excellent properties suitable for ball screws. For equivalent grease

products, refer to the brands specified for the guide (lithium grease).

Note: Never use fluorine grease. If fluorine grease is mixed with lithium grease, the grease function will drop

and it causes damage to the mechanism.

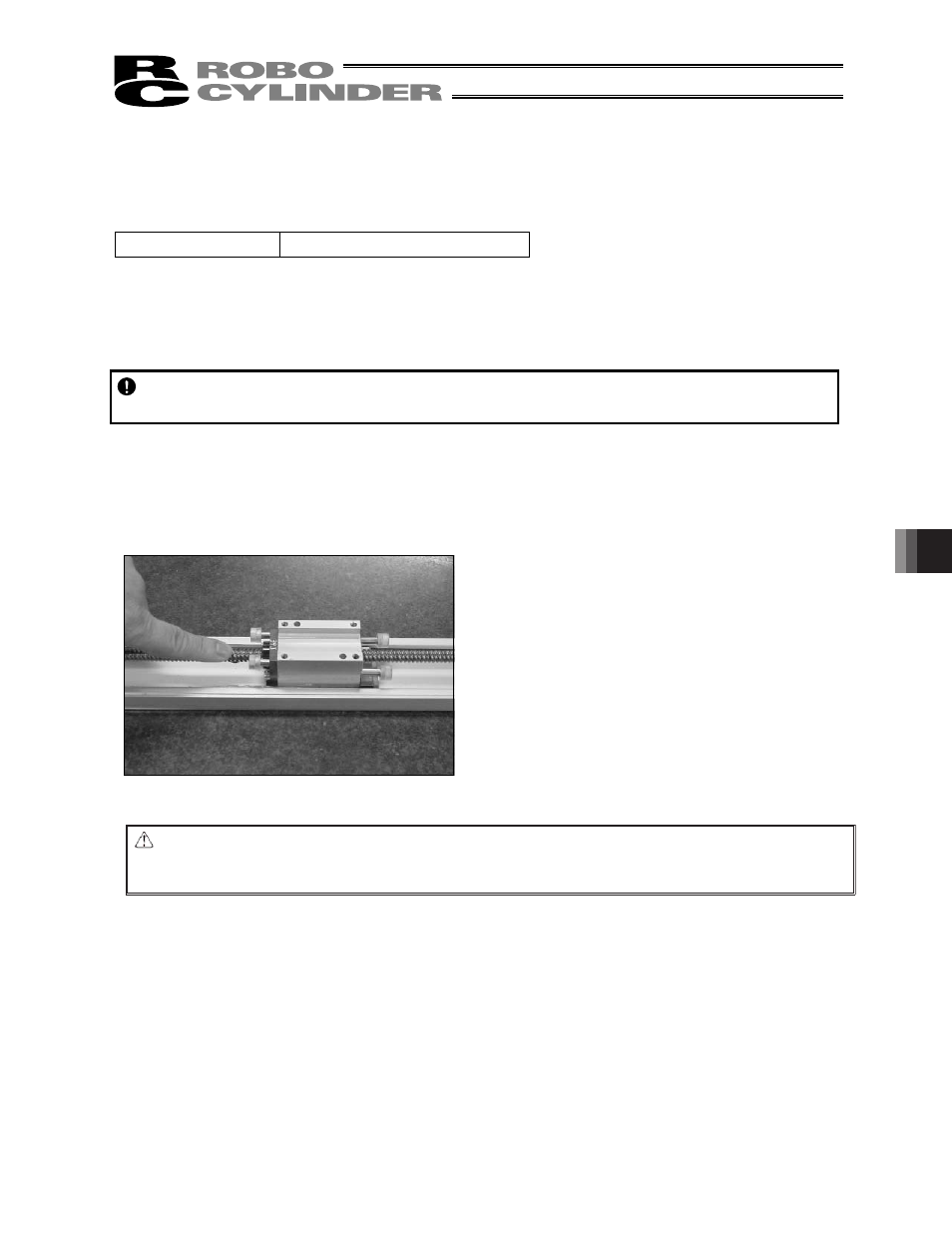

(2) Greasing method

After cleaning the ball screw, apply grease and

stroke the slider to let the grease spread evenly.

As the final step, wipe off excess grease from the

ball screw.

This is because excessive grease will cause the

agitation resistance to increase and allow the ball

screw to generate heat easily. Wiping off excess

grease will also prevent extra grease on the ball

screw from flying off and staining the surrounding

area as the screw turns.

* With the ERC2, the speed will vary depending

on the load. Be careful not to grease the ball

screw excessively.

Caution:

In case the grease got into your eye, immediately go to see the doctor to get an appropriate care.

After finishing the grease supply work, wash your hands carefully with water and soap to rinse the

grease OFF.