3 alarm description and cause/action, 1) operation-cancellation level alarms – IAI America ERC2 User Manual

Page 159

9. T

roubleshooting

136

9.3 Alarm Description and Cause/Action

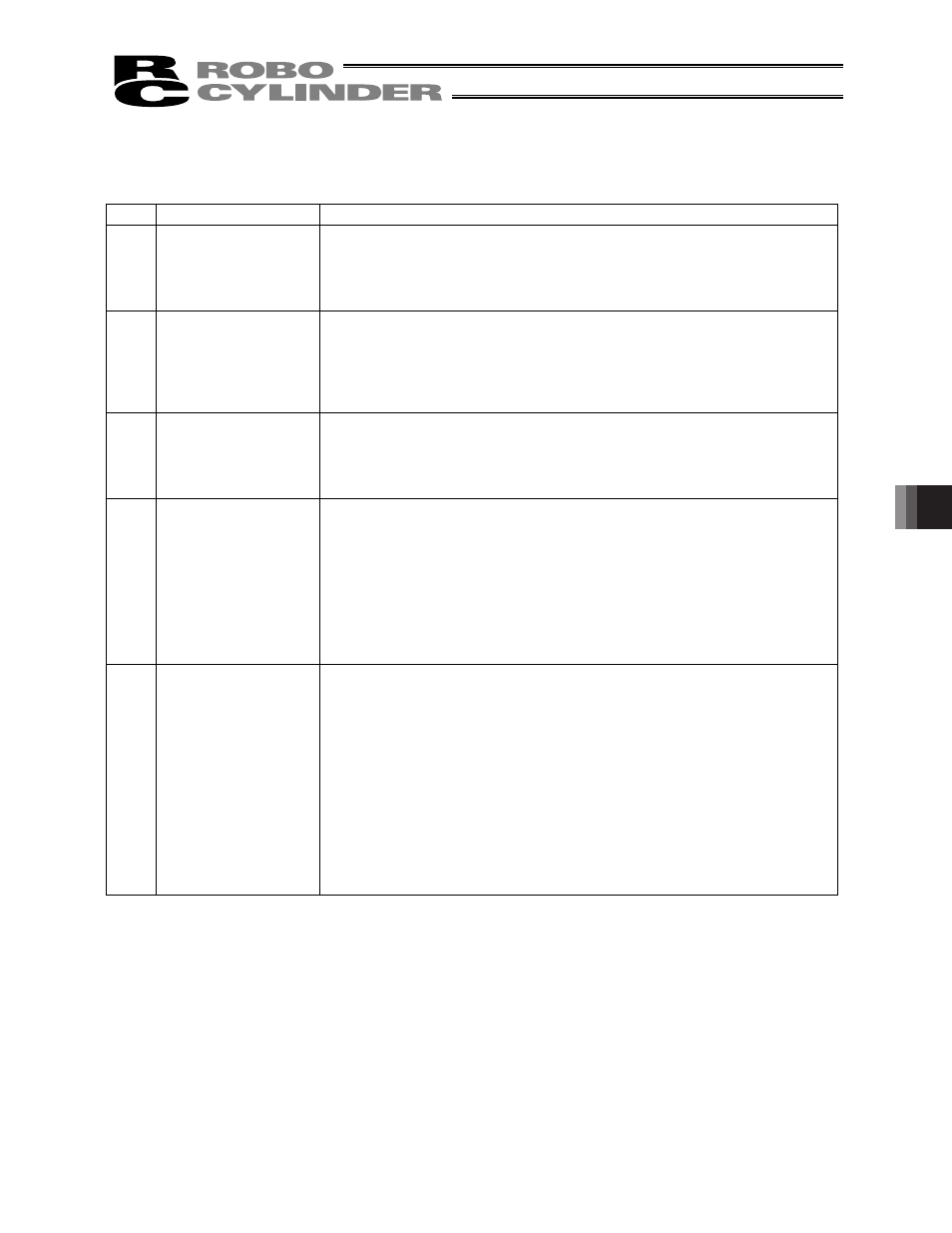

(1) Operation-cancellation level alarms

Code

Error name

Cause/Action

A1 Parameter data error

Cause: The parameter data does not meet the specified input range.

(Example) This alarm generates when a pair of values clearly has an

inappropriate magnitude relationship, such as when the soft limit +

setting is 200.3 mm, while the soft limit – setting is 300 mm.

Action: Change the settings to appropriate values.

A2 Position data error

Cause: [1] A movement command was input when a target position was not yet

set in the “Position” field.

[2] The target position in the “Position” field is outside the soft limit

range.

Action: [1] Set a target position first.

[2] Change the target position to a value inside the soft limit range.

BE Home return timeout

Cause: Home return does not complete within the period set in the applicable

system parameter after the start of home return operation.

(This alarm should not occur in normal operations.)

Action: Inappropriate controller/actuator combination is a possible cause.

Contact IAI.

C0 Excessive actual speed Cause: This alarm indicates that the motor speed exceeded the maximum

speed set in the applicable system parameter.

This alarm will not generate in normal operation, but may occur in the

following conditions:

[1] Large actuator slide resistance in certain area, or

[2] Instantaneous increase in load due to application of external force,

which may cause the load to decrease and actuator to move rapidly

before a servo error is detected.

Action: Check for abnormality in the assembly condition of mechanical parts.

If the actuator is suspected to be the cause, please contact IAI.

C1 Servo error

This alarm indicates that after receiving a movement command the motor is

unable to operate for two seconds or more before reaching the target position.

Cause: [1] Loose or disconnected connector of the motor extension cable

[2] Brake cannot be released on a controller equipped with brake.

[3] Large load due to application of external force

[4] Large slide resistance of the actuator itself

Action: [1] Check the wiring condition of the motor extension cable.

[2] Check the wiring condition of the brake cable, and also turn on/off

the brake release switch to check if a “click” sound is heard.

[3] Check for abnormality in the assembly condition of mechanical

parts.

[4] If the load is normal, turn off the power and move the actuator by

hand to check the slide resistance.

If the actuator is suspected to be the cause, please contact IAI.